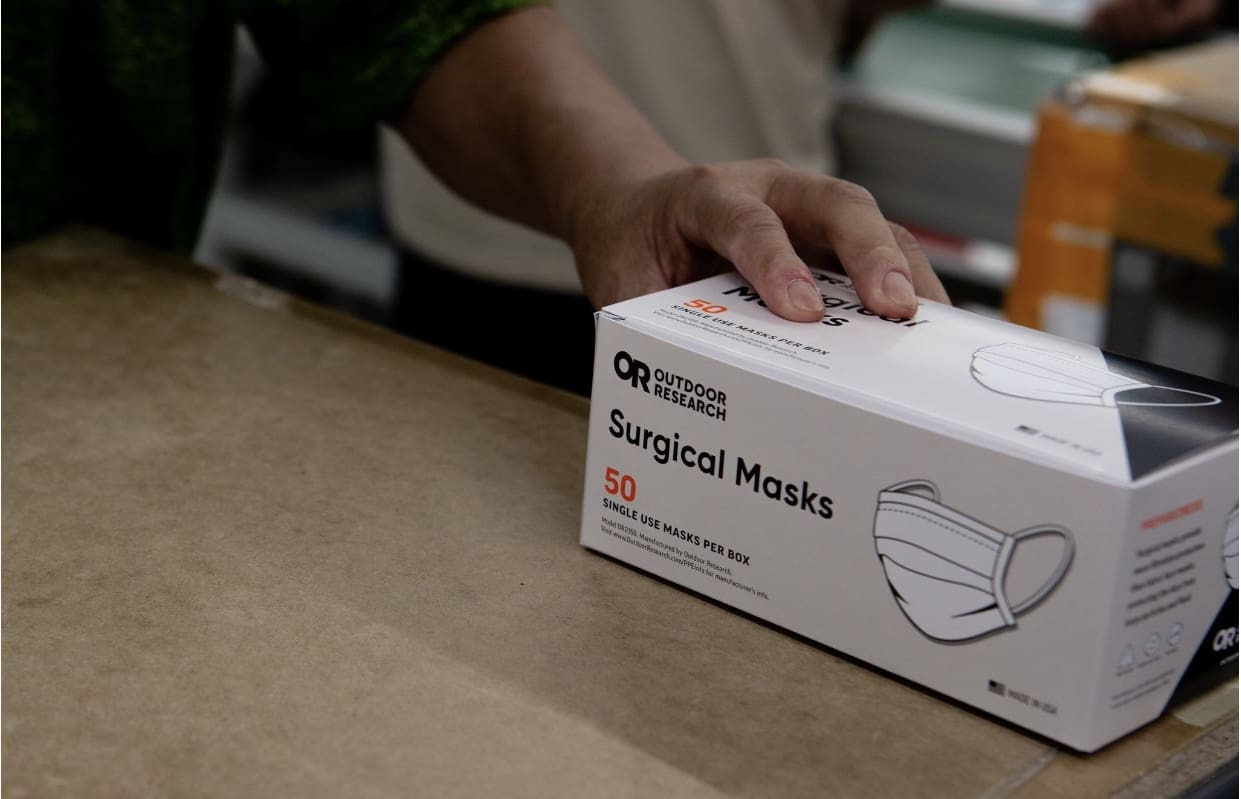

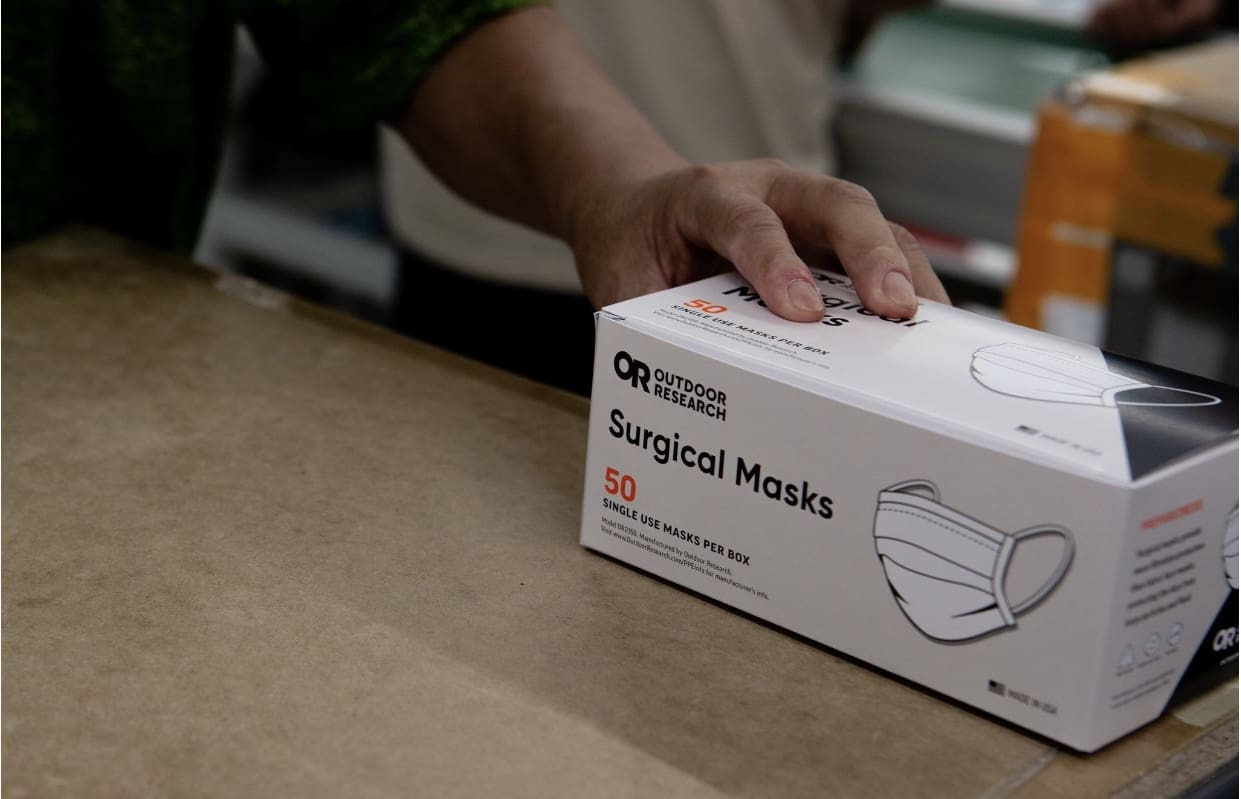

Seattle-based company one of only four companies to achieve FDA authorization for U.S.-made surgical masks since pandemic began

SEATTLE, Wash. – Outdoor Research, LLC. (OR), a leading brand in the tactical and outdoor apparel industries, has earned U.S. Food and Drug Administration Emergency Use Authorization (EUA) for its U.S.-made surgical mask. This authorization is designed to help strengthen the availability of key products needed during public-health emergencies.

FDA EUA authorization follows quickly on the heels of National Institute for Occupational Health and Safety (NIOSH) approval in late July of OR’s Flat Fold Respirator Mask. NIOSH is a division of the U.S. Center for Disease Control and Prevention (CDC).

Federal authorization of OR’s personal protective equipment (PPE) is the culmination of a months-long effort and represents two significant accomplishments. OR is one of only four organizations to achieve FDA authorization for U.S.-made surgical masks since the COVID-19 pandemic began. OR is also one of only six organizations to achieve expedited NIOSH certification to make healthcare respirators since the beginning of the pandemic. It is the only manufacturer within the outdoor and tactical spaces to do either.

While many companies have entered the mask market temporarily by creating “face coverings” for general public use, OR has made a strategic commitment to expanding the company’s manufacturing capabilities to build advanced medical-devices, providing PPE to frontline healthcare workers during and after this current crisis.

“With the onset of COVID-19, it quickly became clear that securing more reliable sources of medical PPE within the U.S. was critical to our country’s response to this pandemic,” said Jason Duncan, Head of Tactical, Innovation and CSR at Outdoor Research. “Because Outdoor Research already had long-established U.S. manufacturing capabilities and the know-how to quickly pivot to building new kinds of technical products, we are able to be part of the solution. These FDA and NIOSH authorizations speak to the success of that effort and to the vast amount of team work that has gone into this here at Outdoor Research.”

In the past five months, OR invested in equipment and training to convert two floors of its Seattle manufacturing facility to produce two different types of N95 masks as well as medical-grade surgical masks. The company also produces the Berry Amendment-compliant Resolute Face Mask in Seattle. Along with investing in equipment, OR has hired more than 130 people to support mask production. These investments have resulted in the capability to produce up to 200,000 U.S.-made masks per day. To date, it has produced more than 3 million U.S.-made masks.

OR is also producing reusable, technical and functional face masks for the general public. Like the Resolute Face mask, the Essential Face Mask Kit features an integrated and replaceable filter.

Highly respected in the outdoor industry for developing functional solutions for extreme environments, OR has a history of successfully leveraging the best commercial market technologies to serve the needs of the armed services and first responders. Over the past two years the company has conducted a comprehensive review of the U.S. supply chain and is in active development with textile mills and materials providers to expand and elevate the capabilities of products that are 100% American-made.

OR has made significant capital investments designed to improve and modernize its Seattle factory. These investments have taken advantage of the company’s global knowledge of design, materials, and innovative manufacturing techniques while producing the next generation of outdoor and tactical products at its facilities. OR has continued to accelerate its product-development cycle, allowing the latest innovations to be rapidly fielded to the end user, helping increase the mobility and protection of soldiers, sailors, airmen, marines, first responders, outdoor enthusiasts, and now the medical community.

For more about Outdoor Research, visit www.outdoorresearch.com.