6 January, 2026 — In an operational environment where precision, safety, and adaptability increasingly define capability, Crucial Defense Technologies is introducing Tartarus™ Gel Binary, a next-generation gelatinous binary explosive designed for tactical breaching, demolition, and specialized energetic applications.

Headquartered in Southwest Florida, Crucial Defense Technologies is an emerging manufacturer rapidly building a reputation for developing compliant, high-performance energetic systems for defense, security, and industrial users. Tartarus™ Gel Binary reflects the company’s focus on modern supply chains, modularity, and operational flexibility.

What Is Tartarus™?

Tartarus™ Gel Binary is a patent-pending gelatinous binary explosive formulation developed to address many of the limitations historically associated with binary energetic systems. A binary explosive consists of two stable components that only become energetic when combined. While binary explosives are not new, prior formulations have delivered inconsistent results or presented integration challenges.

Crucial Defense’s approach differs in that Tartarus™ suspends the fuel component within a proprietary gel matrix, allowing the material to be used in conjunction with plastic housings and polymer-based delivery systems. This capability has historically been a major hurdle for gel binary explosives, particularly for applications requiring integration into modern munition designs.

Extensive internal testing has been supported by independent evaluation. Testing conducted by General Dynamics demonstrated that Tartarus™ achieved a Relative Effectiveness (RE) factor of 1.28 when compared to TNT, the baseline reference for modern explosive testing. While this does not reach the approximate RE of C4 (~1.34), Tartarus™ offers a compelling balance of performance, safety, and logistics.

Unlike traditional high explosives, Tartarus™ is shipped as two non-energetic components that only become explosive once mixed. This approach significantly improves transportation safety, storage longevity, and regulatory compliance, making it particularly attractive for users operating in constrained or expeditionary environments. Tartarus™ also features a lower density of approximately 1.15 g/cm³, compared to TNT’s density of roughly 1.65 g/cm³, contributing to overall weight savings.

Why Gelatinous Binary Explosives Matter

Gel-based binary explosives offer several practical advantages over conventional cast or plastic explosives:

• Conformality: The gelatinous consistency allows Tartarus™ to be molded around irregular shapes and into confined spaces, improving surface contact and enabling more predictable blast effects.

• Reduced Shipping Burden: Traditional explosives such as TNT and C4 are regulated as DOT Class 1 materials, among the most heavily restricted categories for transport. Tartarus™ is shipped as a DOT Class 3 material, greatly simplifying shipping, storage, and handling. In some cases, Tartarus™ can be shipped via common carriers, including expedited options.

• Reduced Sensitivity: When stored and transported as separate components, Tartarus™ remains relatively insensitive to impact, friction, and static electricity. This reduces handling risk and eliminates the need for specialized storage magazines or hardened facilities.

• Pound-for-Pound Performance: With an RE factor approaching 30% greater than TNT and a significantly lower density, Tartarus™ delivers increased energetic output while weighing substantially less by volume.

In practical terms, these characteristics translate into consistent, controllable explosive performance that operators and engineers can rely on, even in environments with limited infrastructure or uncertain supply chains.

Operational Utility and Tactical Value

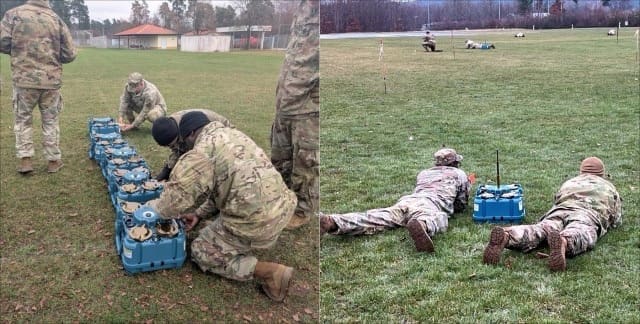

For military and law-enforcement breaching teams, explosive ordnance disposal (EOD) units, and defense engineers, Tartarus™ Gel Binary represents a meaningful shift in how energetic materials can be deployed. Field-mixing capability reduces logistical complexity and allows teams to move lower-hazard materials forward, converting them into an energetic state only when required.

Reduced storage constraints and improved transport flexibility directly support expeditionary operations where weight, volume, and regulatory compliance all influence mission planning. As the saying goes, pounds equal pain — and in aerial and unmanned systems, weight reduction translates directly into increased range, longer loiter times, and greater payload flexibility.

Looking Ahead — The Future of Energetics

While Tartarus™ Gel Binary is still progressing through broader product-development phases, its introduction highlights Crucial Defense Technologies’ growing footprint in advanced energetic materials. As demand continues to increase for safer, lighter, and more adaptable explosive solutions, binary gel systems like Tartarus™ may help define the next generation of tactical energetics.

As field evaluations continue and operational use cases mature, Crucial Defense plans to release additional data covering performance parameters, mixing practices, and integration guidance for military, law-enforcement, and specialized industrial users.

Learn more about Tartarus™ Gel Binary here.