The Big Picture

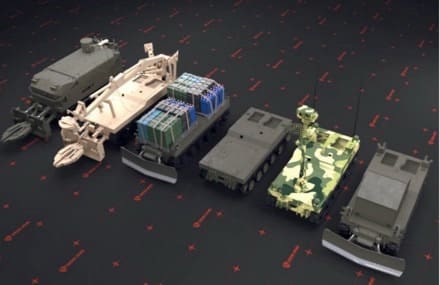

At several 2024 U.S. Army demonstrations such as Project Convergence and Army Futures Command’s Experimental Demonstration Gateway Event (EDGE), Lockheed Martin is demonstrating crewed-uncrewed teaming, uncrewed-uncrewed operations, Artificial Intelligence (AI)/Machine Learning (ML) and integrated systems in various missions relevant to 21st Century Security® in all domains including through the digital frontier.

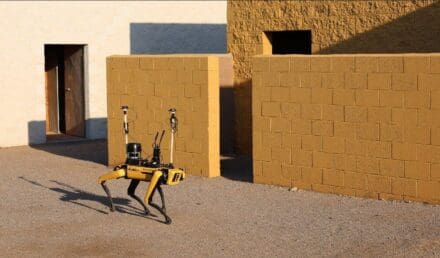

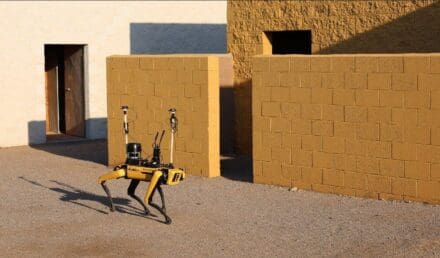

During EDGE, Lockheed Martin conducted highly realistic air/ground teaming scenarios with uncrewed aerial and ground vehicles. A launched effect provided overwatch guidance for a quadruped that navigated urban terrain with human and vehicle obstacles. This technology is designed to operate in environments with degraded or intermittent communications, and scale to many uncrewed systems. Image courtesy DVIDS.

The Details

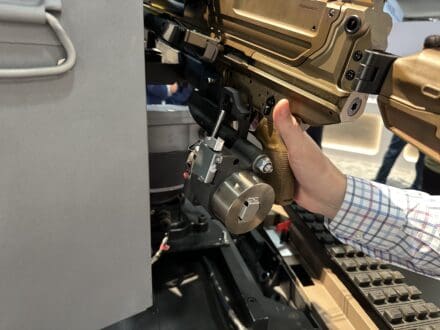

During EDGE, Lockheed Martin conducted successful AI and launched effects demonstrations including rapid integration into Lockheed Martin’s mission systems thanks to the company’s open architecture systems. Image courtesy DVIDS.

During EDGE, Lockheed Martin conducted highly realistic air/ground teaming scenarios with uncrewed aerial systems (UAS), acting as launched effects surrogates, and uncrewed ground vehicles (UGV).

In one mission scenario, a launched effect provided autonomous overwatch guidance for a quadruped that navigated urban terrain with human and vehicle obstacles. This technology is designed to operate in environments with degraded or intermittent communications, and scale to many uncrewed systems.

The successful demonstrations included rapid integration into Lockheed Martin’s mission systems thanks to the company’s open architecture systems.

The scenario played out in the Air-Ground Littoral, an area where the majority of Army operations, both air and ground occur.

Lockheed Martin sees the Air-Ground Littoral as the space primarily occupied by ground forces, supporting helicopters and launched effects, between the ground and up to a few thousand feet of altitude.

Expert Perspectives

Dan Morrison, technical program manager, Lockheed Martin

“Our experimentation is refining autonomous, collaborative behaviors and proving out AI/ML systems in a realistic and challenging environment. Ultimately, this will further enable commanders to better integrate humans and machines in formation and offer increased standoff and reduced workload for Soldiers.”

Michael Harasimowicz, director, AI Innovations, Lockheed Martin

“AI enabling technologies are critical for the U.S. Army to harness decision advantage by extending and expanding sensor understanding at the edge of the battlespace. One day very soon you will see a mission where a Black Hawk helicopter sends information to launched effects that is out ahead of the fight and communicates with a UGV for first contact with the opposing force.”

Going Deeper: The Lockheed Martin AI Center

Lockheed Martin’s AI Center (LAIC), and the experience of our Applied AI researchers combined with the expertise of teammates who are U.S. Army veterans led to the successes at EDGE.

Fifteen members of the LAIC went to Yuma to support EDGE to support five separate AI-enabled capabilities.

“We are demonstrating our suite of AI capabilities for coordinated use and intuitive control across the Air and Ground domain featuring the Lockheed Martin Stalker uncrewed system and a Spot®, Boston Dynamics Quadruped Robot,” said Harasimowicz. “This synchronization of airborne and ground-based defenses demonstrates Lockheed Martin’s commitment to Force Protection Technologies, a key mission for the U.S. Army.”