An area of increasing concern for all of us is the occupied home invasion, which can be defined as an incident where the family occupies the house, and they are confronted with an imminent lethal threat by one or more intruders.

Recently, the number of reported violent encounters inside the home has increased. These violent encounters aren’t even limited to your home anymore. You could be thrust into a violent encounter when shopping at a mall or even walking to your car afterward.

This growing concern has prompted a surge of new gun owners who intend to keep that newly purchased firearm for the primary purpose of home defense. Additionally, many states have adopted constitutional carry where gun owners now don’t need to attend any training to carry concealed.

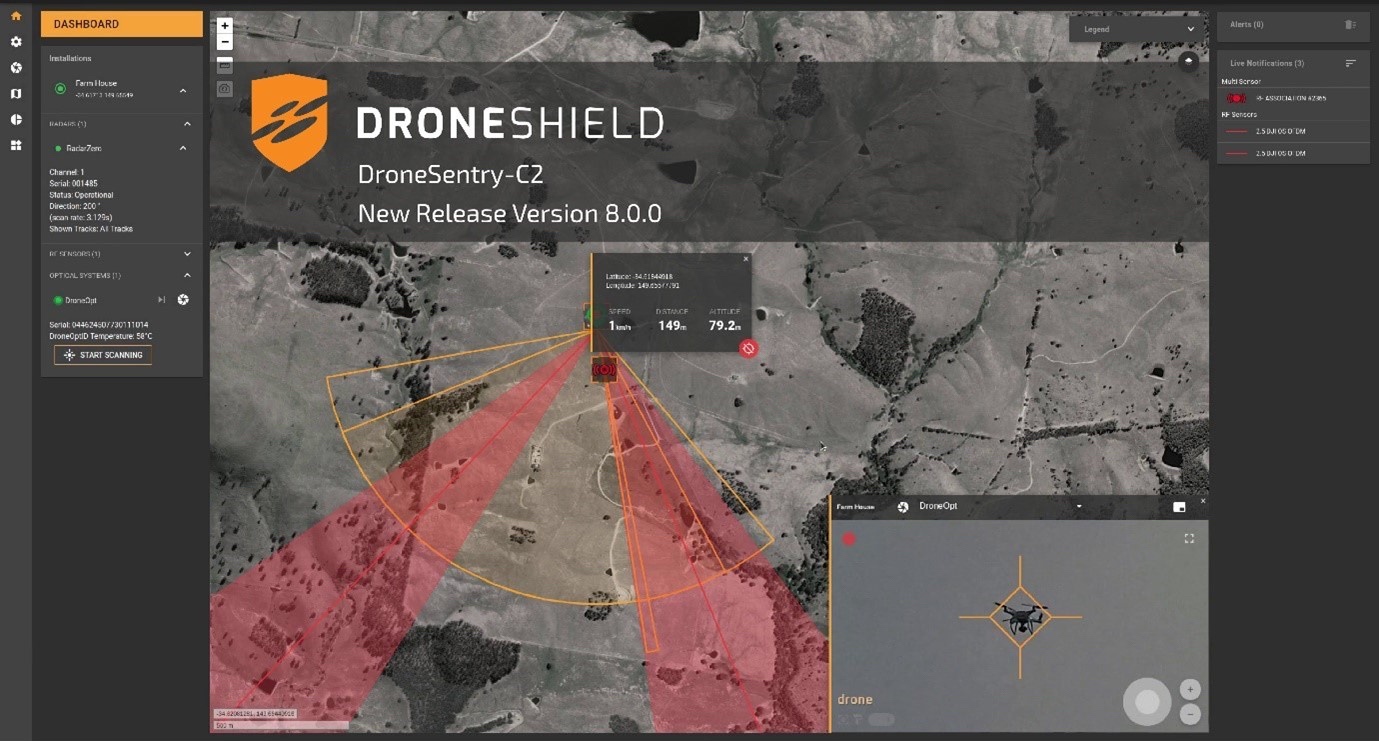

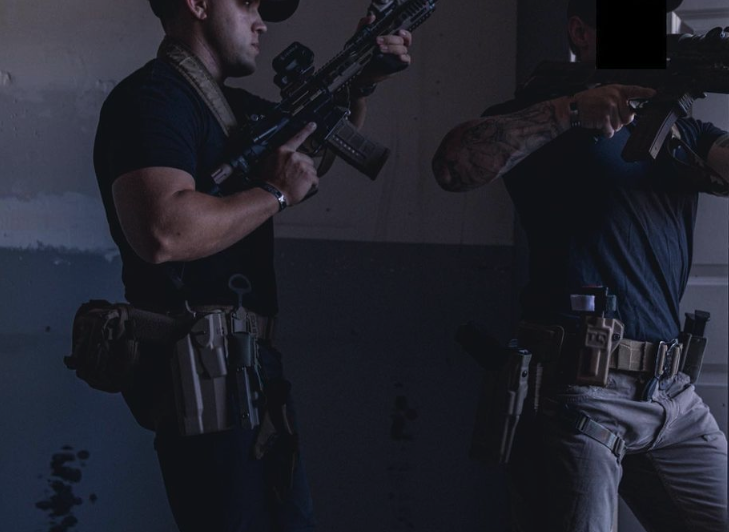

There is a void in the training industry regarding preparing for violent encounters, at least in the context of home defense. Core Vision Training has stepped into that void in a big way.

Why Spend The Money and Time on Training

Self-defense, home defense, and other preparedness training are necessary to effectively defend yourself, your family, and your home when targeted by crime or violence. There will always be criminals who want to take what isn’t theirs and predators who want to hurt the innocent. When you train to become more proficient in these skills, you gain the tools to stand your ground and live to see another day.

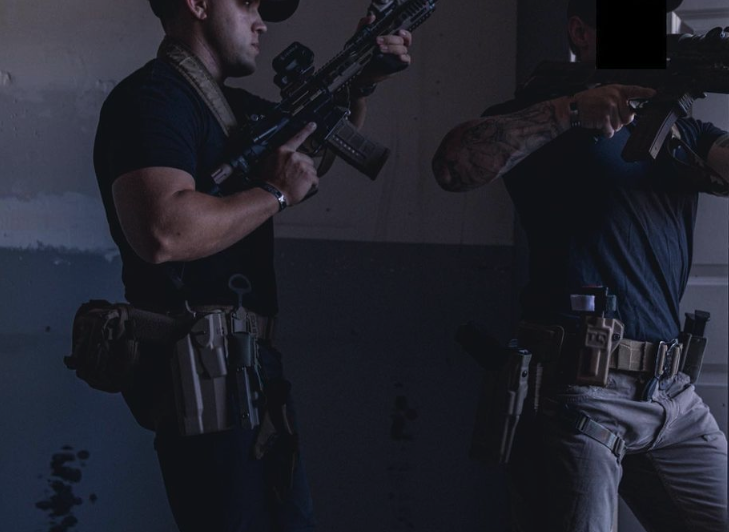

As with any training courses you attend, you want to ensure it fits your context of use and goals. However, many “tactical” training courses claim to train students in the art of fighting with a pistol and rifle, room clearing within your home, and a host of other “tacticool” courses.

Many courses people attend for the experience rather than for learning life-saving skills. Nevertheless, teaching these concepts takes days to execute correctly with the proper instructor cadre.

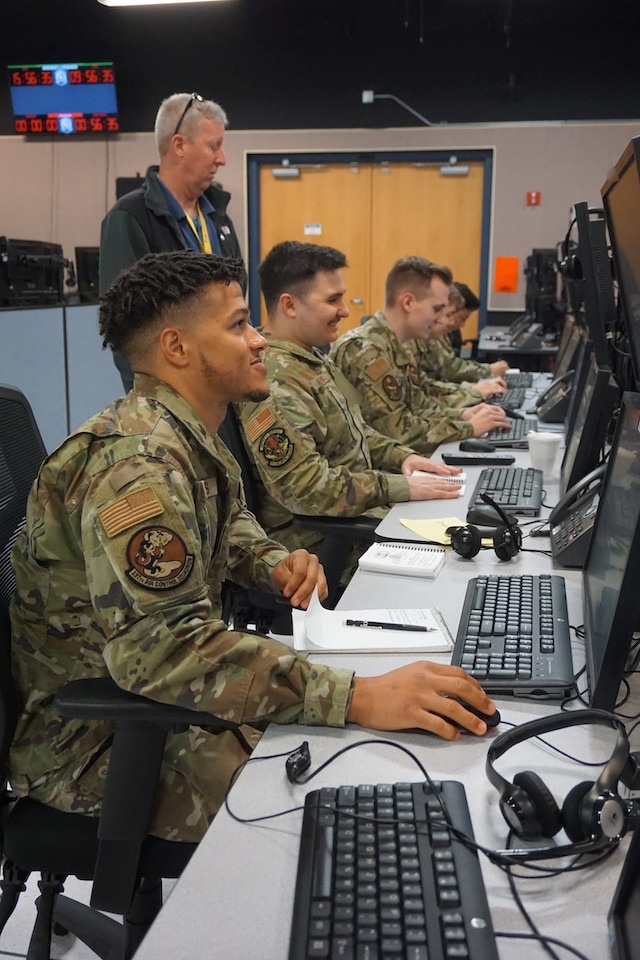

Core Vision Training employs instructors with proven operational experience, some of which are still operational, which gives you the most up-to-date relevant training available.

Why Choose Core Vision Training

Core Vision Training is the top self-defense training company and facility in the Pacific Northwest. Their instructors bring decades of relevant operational experience to provide their clients with the highest quality training possible.

In addition to their premier courses, they also offer a monthly membership program. By signing up for the recurring monthly membership, individuals who have taken any form of our Structure Assessment courses now have the opportunity for additional reps and recurring training to maintain and master the skills they acquired in our classes.

Recurring training covers medical, structure assessment, teamwork, land navigation, live fire, vehicle work, and several more.

Let’s take a quick look at a few of their premier courses.

Structure Assessment Active Defense Course

If you are unlucky enough to find yourself in a fight with an armed assailant, learning to load and clear a malfunction is far easier if you are familiar with that weapon or type of weapon ahead of time. This is something you won’t want to figure out on the fly.

Imagine fighting your attacker in a dark parking lot or inside your home, and gaining control of his loaded weapon, only to die because you didn’t know how to operate the safety.

When you become skilled with your primary defensive tool, learn to use other weapons. Clint Smith said it best “There’s nothing that says you are going to fight with just your gun.”

The Core Vision Training Structure Assessment courses prepare you for just that. The Active Defense course, which is a combination of the home defense course and trauma training, is tailored to the everyday citizen looking to sharpen their skills and better protect their family.

What’s Covered

• 1 & 2 person structure assessment

• CCW Pistol mechanics & manipulations

• Link up procedures

• Casualty assessment and treatment

• Call up procedures for 911

• Center fed, corner fed rooms & hallways

• Positive Threat Identification

Vehicle Escape Concepts

Let’s look at a different type of EDC; your Every Day Car. This is your daily driver, whether a Honda Civic or a Rolls Royce.

When you leave the safety of your home and get into your vehicle to take kids to school, pick up passengers, or go to the store, it becomes your mobile command center.

When you get behind the wheel of your vehicle, think of yourself as the Transporter. It’s not only an excellent movie but highlights some key points. Such as how he maintains driving the car and moves within and around the confines of his vehicle. Everything is done professionally and with a purpose.

The Core Vision Training Vehicle Escape Concepts course teaches you to be ready for a fight in and around your vehicle. Everything they teach you is done professionally and with a practical purpose.

What’s Covered

• Avoidance

• Preparation

• Movement within and out of a vehicle

• What is and is not cover on a vehicle

• Gear & Equipment Preparations

• Vehicle Considerations

Land Navigation

When many of us first enlisted, there was no handheld GPS to tell us where we were and how to reach our destination. Instead, we had to learn how to use a compass and protractor with our maps. Land Navigation courses were taught with the old school military issue Lensatic compasses and a map whether it was daytime or night-time.

The use of a compass is a perishable skill, much like shooting. It requires practice. Nowadays, we have wrist-mounted GPS units, handheld units, and smartphones that provide us with navigational aids. But what if the batteries run out or your GPS gets submerged and shorts out? Now what? How do you get back home? Do you have a backup method of navigation?

The Core Vision Training land navigation course teaches you how to read and orient a map and navigate using a compass so that you make it back home safely. The two available courses are Intro To Land Navigation and Basic Map Reading.

What’s Covered

• How to read and orient a map

• How to familiarize yourself with a map using a compass

• Individual Pace Count

• Dead Reckoning & Terrain Association

• How to identify significant terrain features

• How to identify minor terrain features

• How to read contour lines

• How to plot locations on a map

In the end, the time you invest in training for an event that may never occur is your responsibility. The flip side of that is if that event ever does happen, do you want to be the one who lets your spouse and children down?

We encourage you to reflect on the cost of your personal decisions and how you choose to spend your time and money. Remember, when seconds count, law enforcement is minutes away, and a lot can happen in that time. You can lose your whole world in those few minutes.

If you are ready to accept that risk, that’s on you. But, if you believe your life and the lives of your loved ones are worth every ounce of your effort, train like it. Train like they matter. Train with Core Vision Training.

For more information, you can find them on Instagram, Facebook, and YouTube.