JOB TITLE: Sales (Various positions within Department)

DEPARTMENT: Sales

REPORTS TO: VP of Sales and Department Manager

PURPOSE OF POSITION: To obtain sales personnel with a minimum of two years experience working within sales and sales support teams preferably in the firearms industry. This posting is for the Sales Department. Position can be in Commercial, Law Enforcement, Military or Foreign Sales.

EDUCATION & EXPERIENCE:

Minimum two (2) years’ experience in sales, customer service or military with responsibilities leading to the ability to perform required tasks

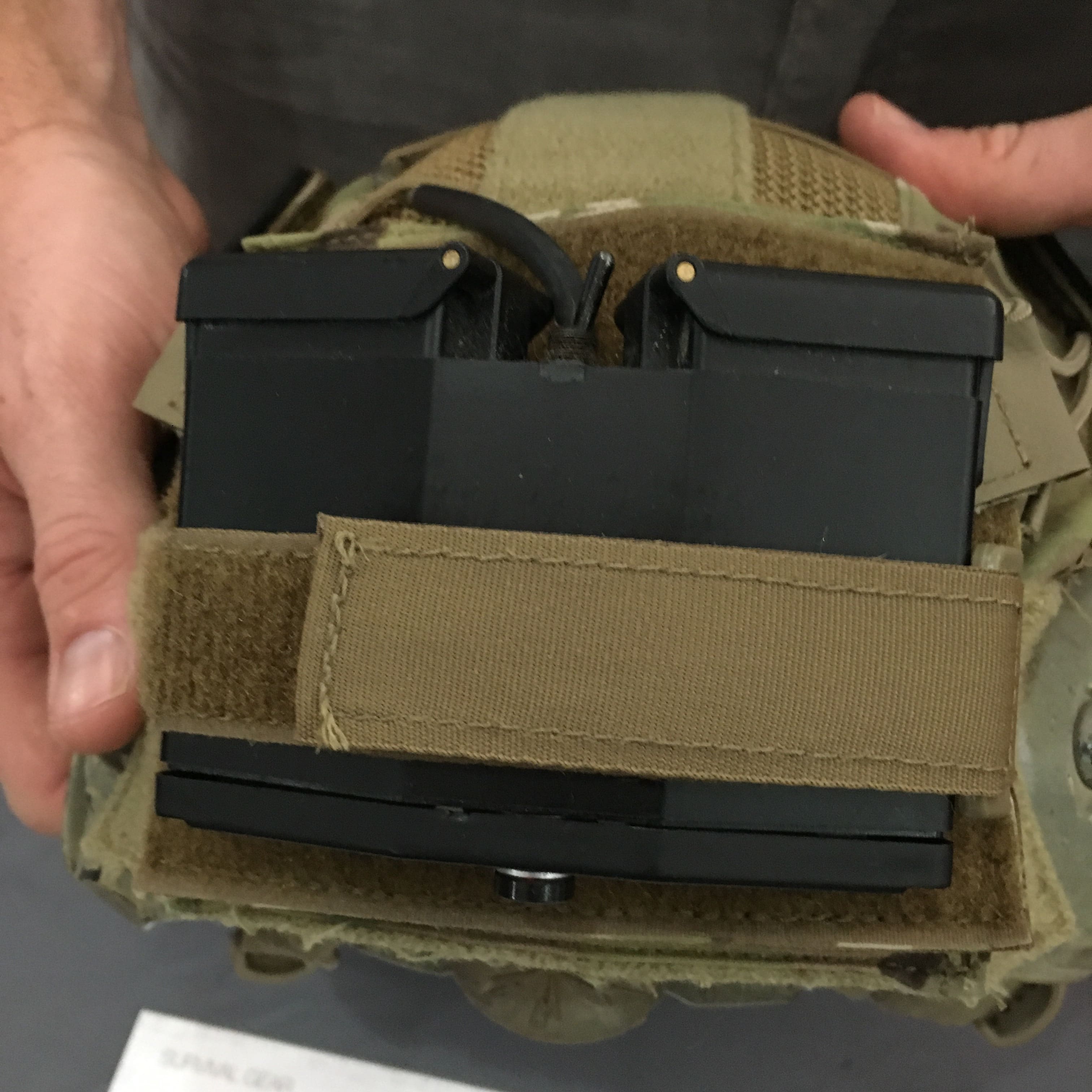

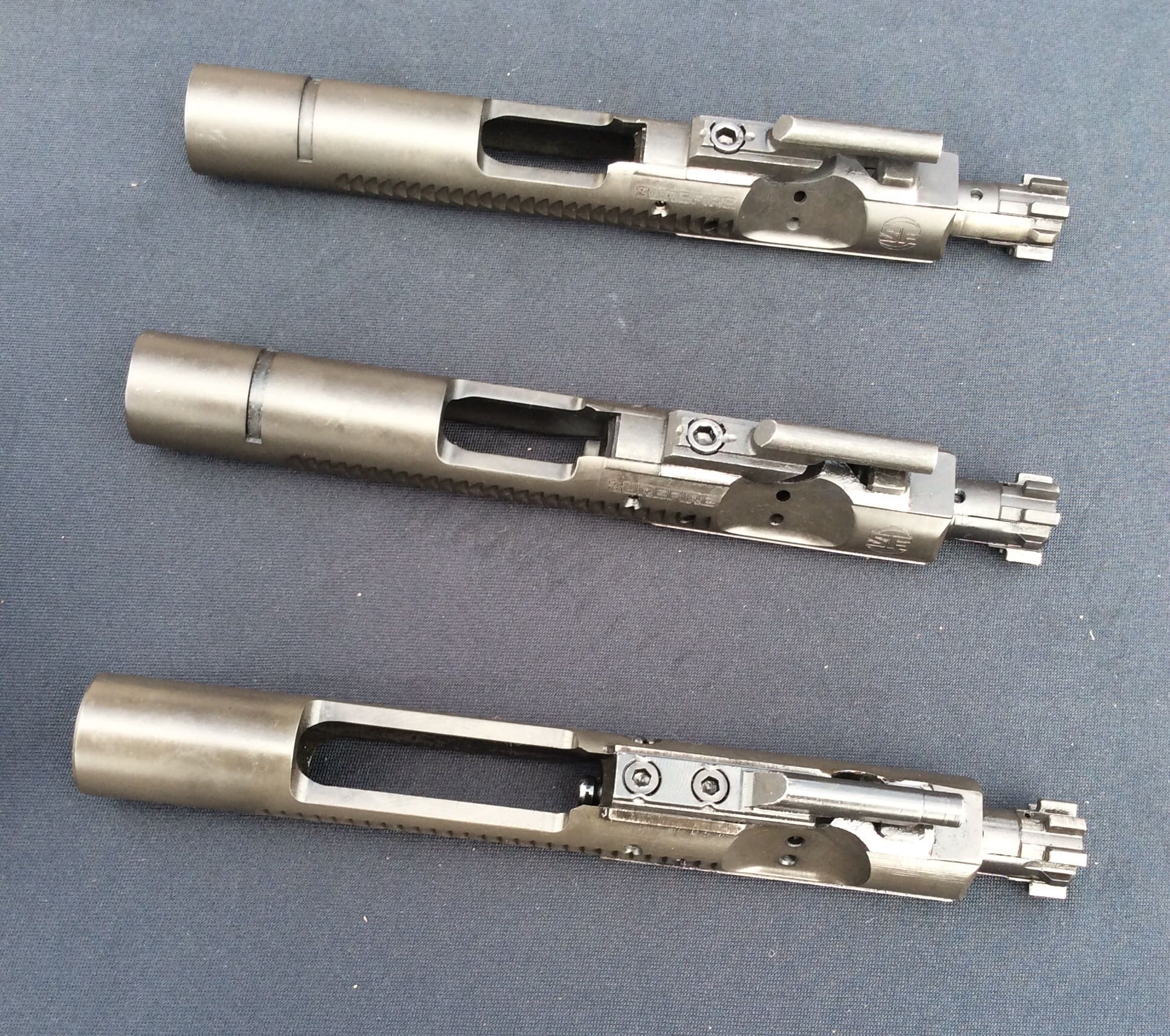

Small Arms or electro-optics experience required.

High School Diploma or GED preferred, however equivalent experience can be substituted.

Strong skills in Microsoft office suite, particularly Excel

Prior MRP experience highly desirable

DESCRIPTION OF JOB DUTIES:

Responsible for managing customer relationship of assigned accounts.

Ensuring that sales and marketing goals of the Company are met.

The initial company point of contact for sales and support of military, government and/or commercial inquiries concerning pricing, availability, part numbers, part descriptions, training and system interoperability.

Actively works with customers to interpret requirements and offer best product solutions.

Prepares price and availability quotations for military government and commercial entities.

Maintain database for pricing history, part numbers and support RFP efforts.

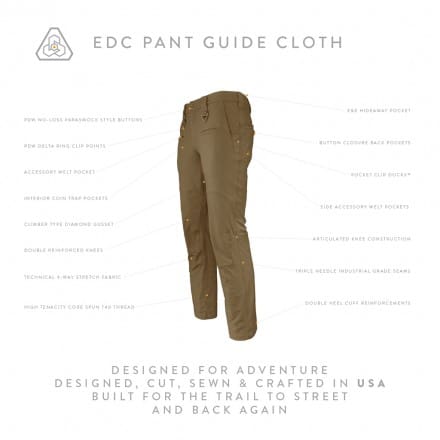

Provides input for commercial catalog creation.

Promote products in favorable manner with intelligence, technical and professional demeanor at trade shows, industry demonstrations and other sales events.

Co-ordinate with Department Manager to ensure that the information given for product catalogs, marketing material etc. is correct and relevant.

Monitors and analyzes sales promotion results to determine effectiveness of promotion campaign.

Keep abreast of general work issues, forecast trends and identify opportunities for improvement of established programs.

Solicit feedback regarding perceived/actual needs/ideas for developing new products and programs.

Will assist in the development of short and long range objectives and recommend goals to management.

Maintain liaison with federal, state and local agencies as required by assigned area.

Consistently follow departmental standards and customer service standards. Perform related duties as required and/or requested by management.

Knowledgeable of our weapon systems and products.

Prior responsibilities relating to military, commercial and foreign sales desired.

Knight Enterprises Management, L.L.C. is an equal opportunity employer and considers qualified applicants for employment without regard to race, color, religion, creed, sex, national origin, age, protected veteran status, disability status, ancestry, ethnicity, gender, gender identity, gender expression, sexual orientation, marital status, or any other protected factor by country, regional or local law. Knight’s policies regarding recruitment, hiring, compensation, benefits, promotions, transfers, training and all other personnel matters are free from discriminatory practices and are based on merit, qualifications, and abilities.

To apply, click here.

To view the U.S. Department of Labor’s (DOL) Equal Employment Opportunity is the Law poster, please go to the following link: www1.eeoc.gov/employers/upload/eeoc_self_print_poster