LENGGRIES, GERMANY, and KOMENDA, SLOVENIA (1 April 2023) — Following on the heels of their successful joint participation at SHOT Show 2023in Las Vegas, U.S.A., UF PRO and Lindnerhof-Taktik have agreed to collaborate further on the creation of special, one-of-a-kind tactical-use products.The two brands say they are united by a shared drive for constant innovation, a love of detail, and a desire for greater creativity. This powerful combination has led UF PRO and Lindnerhof to bring to market a radically new concept, one that takes the product portfolios of both companies to a higher level.

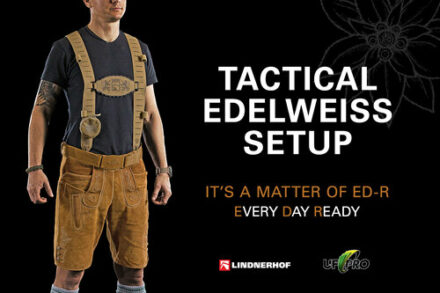

Beginning Saturday, 1 April, the gates will fling open wide for pre-ordering the brands’ hot new tactical Edelweiss set-up consisting of UF PRO’sP-40 Tactical Lederhosenof UF PRO and Lindnerhof’s matching and adaptive Chest-Rig Harness Edelweiss BY732.

Said Armin Wagner, Head of Product Development at UF PRO, “Never settle for ordinary Lederhosen when you can experience the comfort, style, and adaptability of our P-40 Tactical Lederhosen, which features the innovative Waist/Flex System and scholler®-dynamic stretch material to ensure a comfortable fit for all your Oktoberfest adventures.”

However, the advantages of the P-40 Tactical Lederhosen don’t end there. Equipped with an array of pockets—including cash pockets for your expenses, a dedicated coaster pocket, and even pockets for pens and knives—these Lederhosen are the ideal companion for any unpredictable situation, Wagner contended. “And yes, they’re Knee-High-Socks-ready, so you can maintain that authentic Bavarian look without sacrificing practicality,” he added.

Jakob Kolbeck offered insights concerning the process by which the product was developed: “In the course of discussing the initial design concept, it was clear that we needed to come up with something that would enable our customers to stay tactically ‘cool’ during their free time—and also to allow us,as a Bavarian-based company, to include the look of our traditional Alpine costume.”

The Chest-Rig Edelweiß BX732 is classically designed but with softer padding and extra MOLLE/PALS slots and loops for carrying additional equipment (such as hydration tube guides, cable guides, and more). Moreover, users can personalize the Chest-Rig by means of MOLLE fixation with just a bit of adaptation to the traditional design and included center part.

Included with the Chest-Rig is the BY623 Multi-Purpose Pouch Edelweiß – a small,round multi-purpose bag that provides storage space for AirTags, beer tokens, coins, snus, and all other EDC items.

The Chest Rig also offers the necessary adaptation points for UF PRO’s XXXPants so that set-up users can enjoy additional safety, loss protection, freedom of movement,and above all, comfort in EVERY situation.

Kolbeck promised, “You will love wearing this combi—let’s call it tacti-cool or ED-R, meaning Every Day Ready! And not just for your trip to the world’s largest folk and beer festival.”

For more information about those products of each respective brand, please visit UF PRO’s website at ufpro.com and Lindnerhof’s webshop at hqg.de.