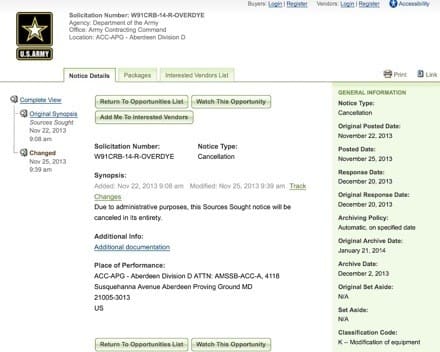

UPDATE – And it’s cancelled. This is becoming comical.

I’ve written several articles about the US Army’s impending change from the ill-named Universal Camouflage Pattern to the newly renamed Operational Camouflage Pattern also known commercially as MultiCam by Crye Precision. I’ve even mentioned a plan to repurpose current stocks of UCP equipment such as MOLLE and IOTV covers to a new, more usable colorway. But how do you change the colors of billions of Dollars worth of equipment? The answer is simple; you dye it. Think of it as a means to cut their losses.

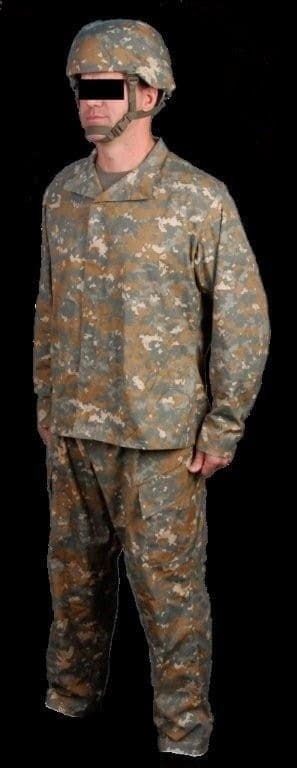

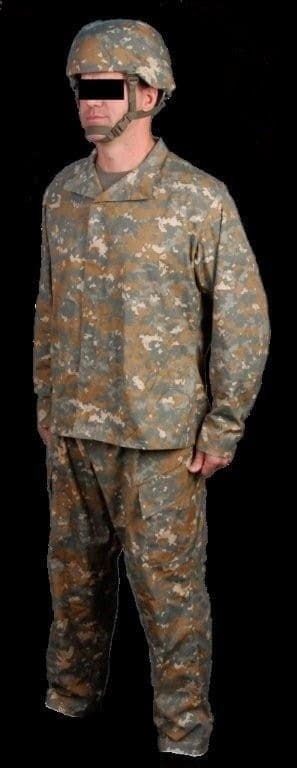

Earlier this year I began to hear reports that the Army had been working with a commercial vendor to develop a process to over dye UCP equipment with a shade of Brown in order to make it more compatible with OCP. Naturally, there are issues afoot here. For example, different materials are going to absorb the dye at different rates, and equipment exhibiting differing levels of wear will also absorb dye differently. In the end, it’s going to look rather interesting. It isn’t going to blend in so much as not clash, like traditional UCP would against OCP. Best case, it may end up somewhat resembling the brown-based UCP-Delta pattern tested in Afghanistan in 2009. Worst case? I shudder to imagine.

Specifically, the Army has issued a Sources Sought Notice. Interested parties have until 20 December, 2013 to respond. The link to the notice is www.fbo.gov.

Subject: Request for Information to Over-dye Nylon Fabrics and Items

Project Manager Soldier Protection and Individual Equipment (PM-SPIE) of the Program Executive Office (PEO) Soldier, Fort Belvoir, VA 22060 is seeking information from potential industry partners to provide a technology solution to modify the camouflage pattern on current equipment. The potential development effort is to over-dye items and/or fabric comprised of nylon 500D and 1000D. Specific items include the Modular Lightweight Load carrying Equipment (MOLLE) and Improved Outer Tactical Vest (IOTV). Items are treated with water repellant, polyurethane, and fire retardant on some equipment. The objective is to modify the Universal Camouflage Pattern (UCP) to more closely match the shade/color of Operation Enduring Freedom Camouflage Pattern (OCP). Of particular interest are portable technologies that can be utilized outside of the manufacturing environment.

Where will it be used? Your guess is as good a mine. Assuredly, it will be issued to the training base so anyone who attends BCT, AIT, Ranger School or any other resident school that issues TA-50 will see this stuff for years to come. Incidentally, TA-50 gets its name from Common Table of Allowances 50-900, Clothing and Individual Equipment which authorizes items for issue based on duty position, unit of assignment or climatic zone. Some of these over duded items may also end up in the reserve components but there has already been some pushback from National Guard commanders who refuse to be looked at as a second class force with second class equipment after being so active over the past 12 years in the war effort. But, over time we will see attrition and replacement of this over dyed UCP. And, I want to mention that the most recent MOLLE contract was only for OCP and the Army has stopped purchasing MOLLE in UCP.

Some have pointed to recent articles published by the press regarding statements by Army spokesmen to suggest that my evidence that the Army is marching ahead with the camouflage change is incorrect. If so, why would the PEO Soldier put out a call to industry just this past week looking for firms that are capable of over dyeing TA-50 if they weren’t still planning to make the camouflage switch?