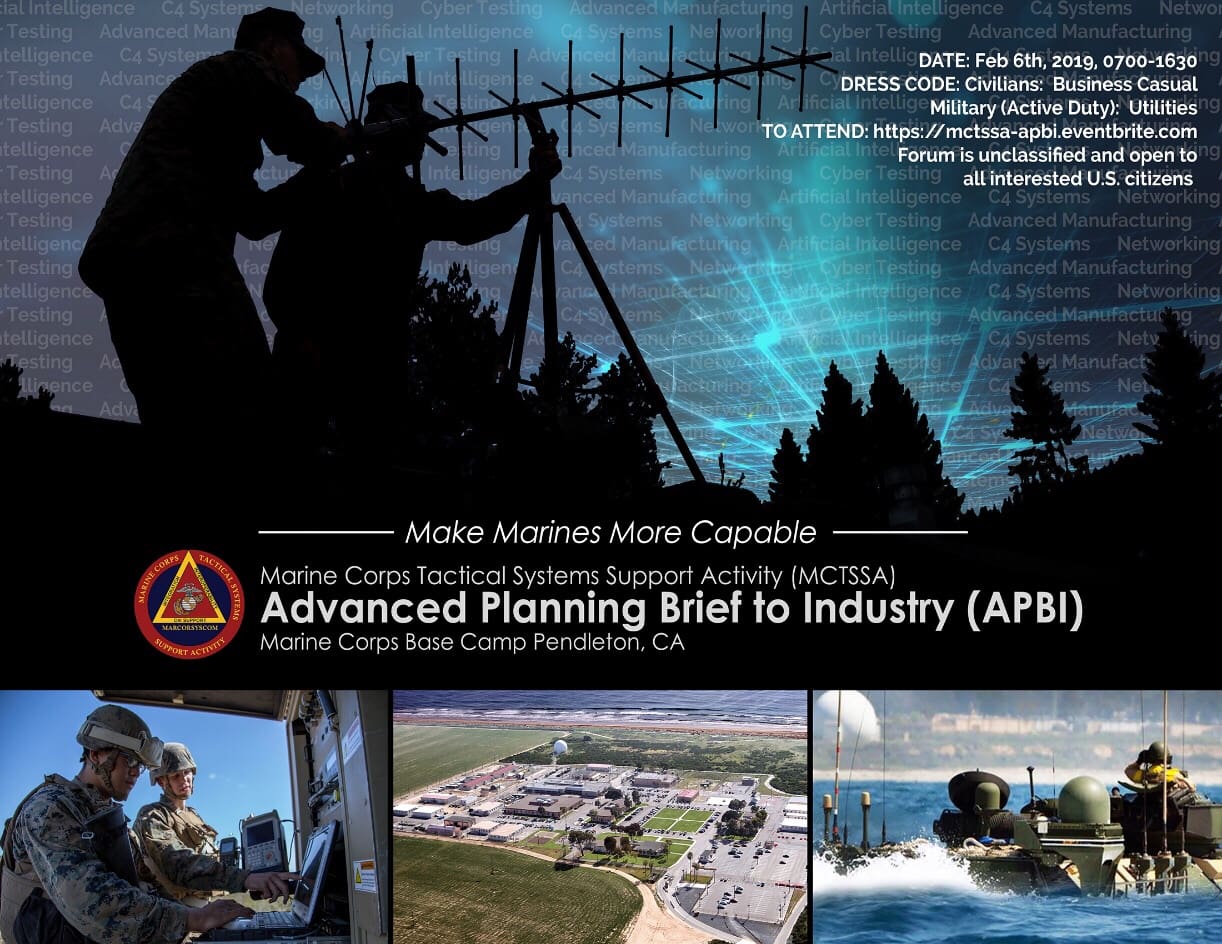

CAMP PENDLETON, Calif.— Marines, engineers and technical experts from Marine Corps Tactical Systems Support Activity hosted nearly 200 business leaders from across the country during an Advanced Planning Briefing to Industry Feb. 6, aboard Marine Corps Base Camp Pendleton.

Marine Corps Tactical Systems Support Activity hosted nearly 200 business leaders during an Advanced Planning Briefing to Industry Feb. 6 aboard Marine Corps Base Camp Pendleton. (Photo Illustration courtesy of U.S. Marine Corps)

The one-day event highlighted current technical objectives and associated challenges involved in supporting the command, control, communications and computers—or C4—systems used by expeditionary warfighters.

“The mutually beneficial partnership between private industry and the United States Marine Corps is our competitive advantage,” said Col. Robert Bailey, MCTSSA commanding officer. “Our talented business partners will be the ones creating the next generation of C4 systems, which must integrate seamlessly with the Marines operating at the tactical edge of the network.”

Specific areas discussed were, cybersecurity testing, wireless technology, advanced manufacturing, cloud computing, naval systems integration, automated testing, systems engineering, system and system of systems testing, data link analysis, tactical networking, and United States Marine Corps Operating Forces technical support.

Industry partners gathered with MCTSSA subject matter experts during an Advanced Planning Briefing to Industry Feb. 6 aboard Marine Corps Base Camp Pendleton.

“MCTSSA is doing some exceptional 21st century work for our Marine Corps,” said APBI participant and marketing director Greg Goodman. “This was a superb event.”

Other participants sought to gain knowledge of the technologies and processes that are important to the United States Marine Corps.

“MCTSSA and industry are trying to solve the same problems, there is a significant opportunity for cooperation if a business model can be worked out,” said James Valentine, a business development director.

Col. Robert Bailey (left), MCTSSA commanding officer, spoke with business leaders during an Advanced Planning Briefing to Industry Feb. 6 aboard Marine Corps Base Camp Pendleton.

Technical briefs were conducted at various locations throughout the MCTSSA compound and put the command’s subject experts in direct contact with their business counterparts.

“I’ve been able to learn more about command requirements and how Hewlett Packard Enterprise can assist,” said Ray McCrea, an account manager and APBI participant. “By starting that dialogue and meeting these contacts, I’ve accomplished my goal here today.”

Hearing directly from requirements officers was beneficial to many of the industry participants.

“Partnerships are vital in creating win-win relationships,” said APBI participant Wil Granados. “I am extremely supportive of these type of events and would like to see more in the future.”

Buck Connally (right), a MCTSSA subject matter expert, briefs industry leaders on joint interoperability of tactical command and control systems during an Advanced Planning Briefing to Industry Feb. 6 aboard Marine Corps Base Camp Pendleton.

MCTSSA leadership echoed similar sentiments.

“Cultivating and enhancing our relationship with industry will become even more essential as our nation faces new and evolving threats from a strategic and asymmetric adversary,” said Bailey. “We must make Marines more capable, enabling combatant commanders’ real-time command and control superiority and this industry event helps us strive to do just that.”

Business leaders taking part in the event equally expressed the importance of the day.

“These are valuable interchanges for industry,” said Valentine. “It ties industry into the Marine user through MCTSSA and will help steer our investment.”

MCTSSA, an elite, full-scale laboratory facility operated by the Marine Corps, is a subordinate command of Marine Corps Systems Command. MCTSSA provides test and evaluation, engineering, and deployed technical support for Marine Corps and joint service command, control, computer, communications and intelligence systems throughout all acquisition life-cycle phases.

Story and Photos By Sky M. Laron, Public Affairs Officer, MCTSSA