SCUBAPRO’s FRAMELESS mask is diving’s original frameless mask. The Frameless was the first mask to use the lens as its structural support, which significantly increased the field of vision for divers. Twenty-one years later, it is still the first choice of military and technical divers.

Its distinctive rectangular single-lens shape is classic, providing an excellent field of view on the periphery as well as straight ahead. By eliminating the frame, you create a mask that sits closer to your eyes. This provides a broader field of view to better take in the underwater sights, plus it reduces volume, which makes it easier to clear. Also, since there is no frame, the buckles attach directly to the skirt. This enables the mask to fold relatively flat for packing or for slipping into a BC cargo pocket. The soft silicone skirt on the FRAMELESS is comfortable yet durable, and the double-edge seal feels good against the skin. Buckles attach to flexible tabs on the skirt; this optimizes strap angle when dialing in the fit.

SCUBAPRO wanted to give it an update without taking away from its already iconic features. We also wanted it to work with our newest dive computer, the Galileo HUD. So, we develop a way to mount the HUD to the mask as the mount needs a hole drilled through the lens, which can only be done before the glass is tempered.

SCUBAPRO is always trying to innovate for the working divers and set the standard for new gear. The latest features for the Frameless/ Frameless Gorilla mask are the addition of the comfort strap adapter. They can be added onto existing masks, and this allows the user to add several new features to one of the most iconic masks ever made. We have new accessories for the classic Frameless mask. The latest version of the Frameless that is available with an integrated HUD Arm that allows you to mount the SCUBAPRO HUD hands-free dive compute.

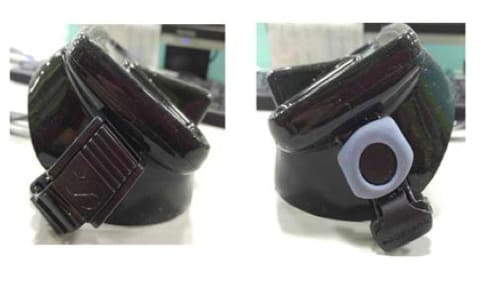

SCUBAPRO has also been working with some military units to make the Frameless mask non-magnetic. To do this, we decide to develop a conversion kit so it could use our comfort straps. With this, we removed the springs and pins in the mask straps. QR kit Part Number 24.340.039

The Frameless adapter kit includes two quick clips and the roll pins. The adapters also allow you to use the SCUBAPRO Odin Helmet Straps. Ops-Core is the primer brand when it comes to helmet innovation. The Odin system allows any mask with quick clips to be attached to any helmet that has the Ops-Core ARC rail systems. The Odin straps are perfect for any time you have to wear a helmet when diving or in the water. Like using a DPV, Wearing Jet-boots, Search and Rescue Operations, or working in Fast Moving Water. The Comfort Strap is similar to a ski goggle strap in design. It clips right into the mask buckle adapter and offers a wide adjustment range. It also is a lot less likely to break mid-dive as it is a nylon strap and not rubber or silicone. The adapter also makes the mask non-magnetic for EOD use, as it removes all metal parts.