PATRICK SPACE FORCE BASE, Fla. – Scientists and engineers across the U.S. Air and Space Force are being deployed to more than a dozen bases in the United States to develop innovative solutions to a variety of problems.

The Airmen and Guardians are part of Project Arc, a program that sends scientists and engineers to 13 bases in nine states where they use their skills to promote innovation and enhance mission efficiency.

“We need to be able to solve problems faster and with this program, we can put scientists and engineers side by side with operators to solve problems,” said Capt. Jason Goins, Air Force Technical Applications Center assistant director of operations and Project Arc manager.

“We talk about if we don’t accelerate change, we will lose,” Goins said. “And we know the next battlespace is going to be technologically focused. This is how we get after that. Our greatest strength is our diversity. Our advantage is our Airmen and Guardians. By taking advantage of their talents, we can deliver real time capabilities at the point of need.”

One Project Arc mechanical engineer deployed to Joint Base Pearl Harbor-Hickam, Hawaii, in October 2021. That engineer cut a monthly inventory check from eight hours to 20 minutes by automating tasks and using weight-based systems, Goins said. This saves “five-man weeks a year” at one base.

A team of computer scientists at Joint Base Andrews, Maryland, in November 2021, developed a software prototype for centralizing repair facility work order management that accelerates the repair process and saves 2,000-man hours a year, the captain said. The innovation is currently being considered for implementation across the service.

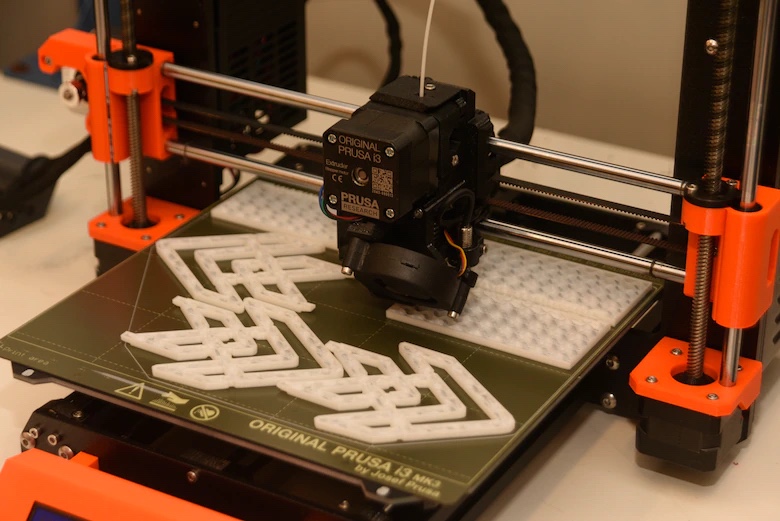

“The acquisition processes are in place to develop solutions, but they can take time to manifest and implement, so we are here to look at problem sets that are small in nature but can be scaled quickly through the products we develop,” said Space Force 2nd Lt. Kevin Tran, Space Analysis Squadron developmental engineer, Wright Patterson Air Force Base, Ohio.

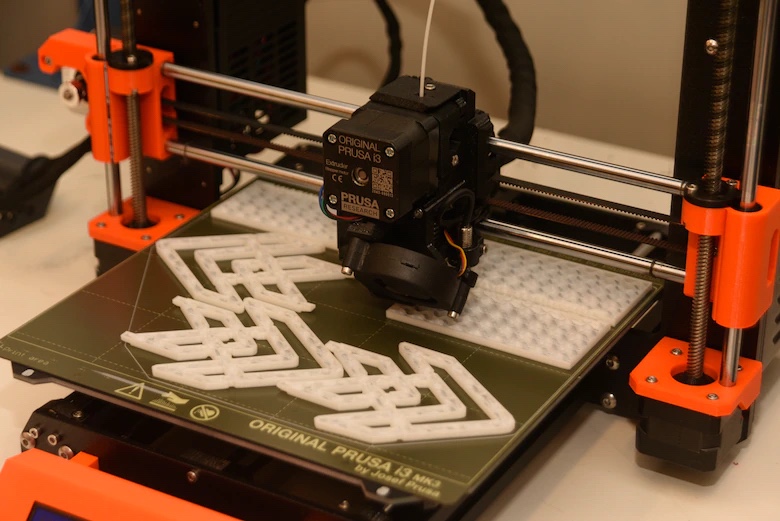

Tran is deployed to Patrick Space Force Base, Florida, where he works alongside Air Force 1st Lt. Kennith McLoud, Air Force Operations Test and Evaluations Center operations research analyst, who is deployed to Patrick from Eglin AFB, in Space Launch Delta 45’s innovation center, The Forge.

Since the duo arrived in April, they have met with several units at Patrick and Cape Canaveral Space Force Station. Those meetings identified several concerns including the damage corrosion causes, as well as the need for a medical training interface and a collaborative space launch environment where all launch data is centralized in one place.

“Corrosion is a big problem we are working on right now,” McLoud said. “Just from all the salt from the ocean and ultraviolet light, the environment is highly corrosive. Because of that the HVAC (heating, ventilation and air conditioning) chillers, which cool buildings and are supposed to last 15–20 years, are only lasting for four or five years.”

Research discovered corrosion was eating away the material the chillers are made of which eventually causes them to break down and be replaced.

Corrosion is also a concern of the 45th Logistics Readiness Squadron. The unit manages SLD 45’s government vehicle fleet.

“Many of those vehicles have to be serviced by a third-party company about every two years because the coating they’re using now isn’t holding up well,” McLoud said. “We discovered a silicon ceramic non-conductive coating that can be applied to multiple surfaces to prevent corrosion. That is something that can be used to extend the life of the chillers, protect government vehicles, and even extend the life of lighting fixtures.”

The coating can extend the life expectancy of HVAC systems and vehicles by at least four or five years, Tran added. This could lead to an estimated savings of $100,000 in annual maintenance costs.

Tran and McLoud are currently working on a dozen projects to enhance the space launch mission.

“Our adversaries are developing different ways to launch their payloads into orbit and if we don’t find ways to innovate, we will not be able to secure space and ensure access to space the way we want to,” Tran said. “We need to constantly push ourselves, take advantage of the expertise of our Airmen and Guardians, and help our warfighters. When we stop innovating, we start to lose the fight.”

McLoud echoed Tran’s sentiment and said he hopes Project Arc continues to grow.

“We have the capability, the Airmen and Guardians to do so many things,” he said. “We have people who know how to program, code, and so much more who can save money, several man hours, and enhance our mission, so why not? Let’s Invest in our Airmen and Guardians, so they can use their skills to advance our mission.”

By TSgt James Hodgman, Space Launch Delta 45 Public Affairs