I recently made a visit to SIG SAUER’s newest factory in Rochester, New Hampshire. This 200,000 square foot facility started out in a different industry and has been repurposed several times since SIG started using it but they are adapting it quickly to their purpose. SIG began occupying it in the spring and by summer there were over 300 employees working on the floor. Envisioned as additional capacity to accommodate machine gun manufacturing, the factory is accomplishing a variety of tasks as they ramp up to meet the upcoming demands of the Next Generation Squad Weapons program.

For example, one of the new capabilities developed for this factory is in-house magazine production for NGSW.

During the down select process, SIG used a modified version of the 20 round Lancer L7AWM polymer magazine. However, SIG has begun development of a stamped steel magazine.

The Army has not evaluated this magazine yet due to the stop work order associated with Lone Star Future Weapon’s NGSW contract award protest. Consequently, although the magazine production capability is primarily envisioned for NGSW, the team is currently refining the process by producing pistol magazines.

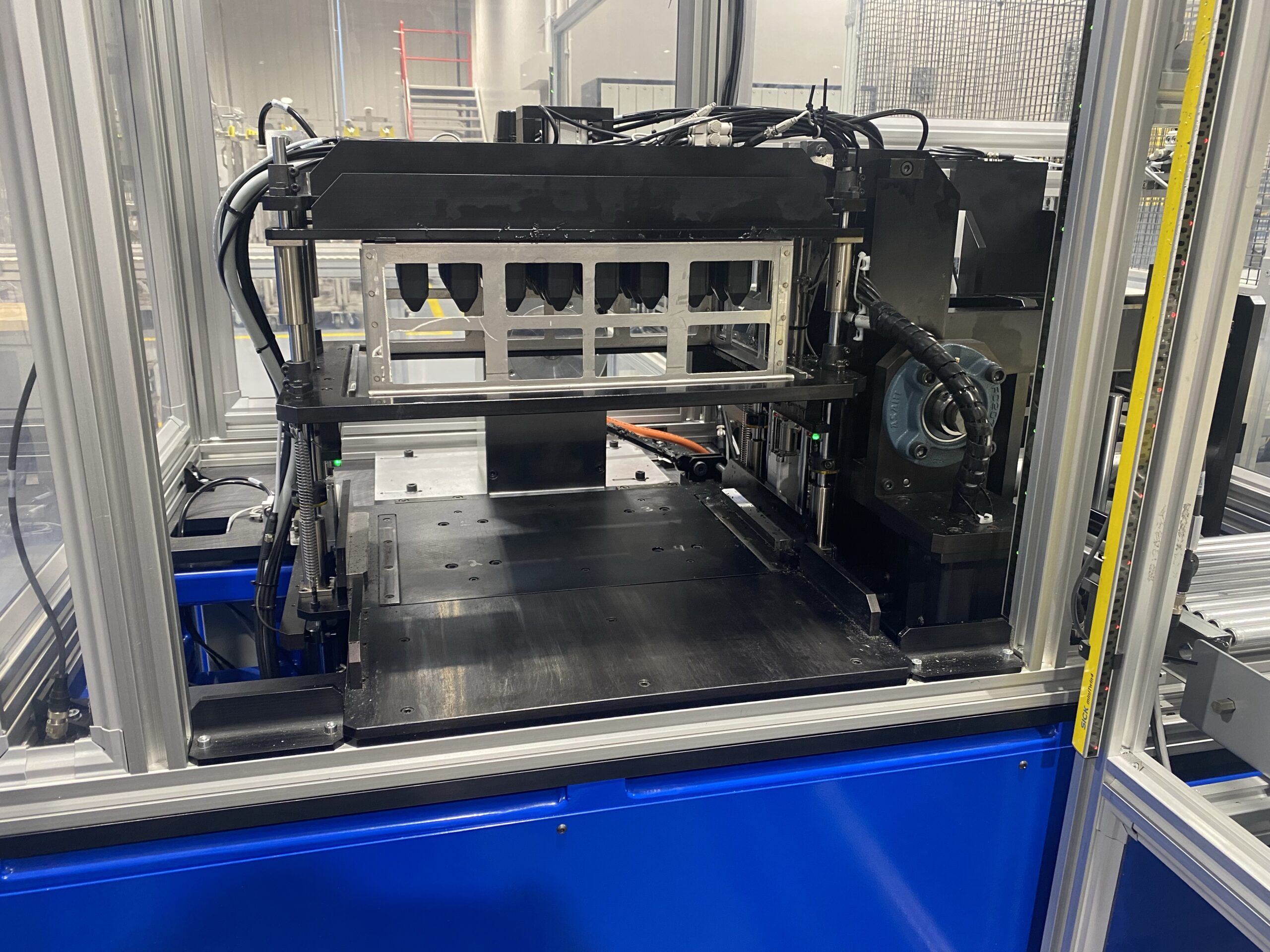

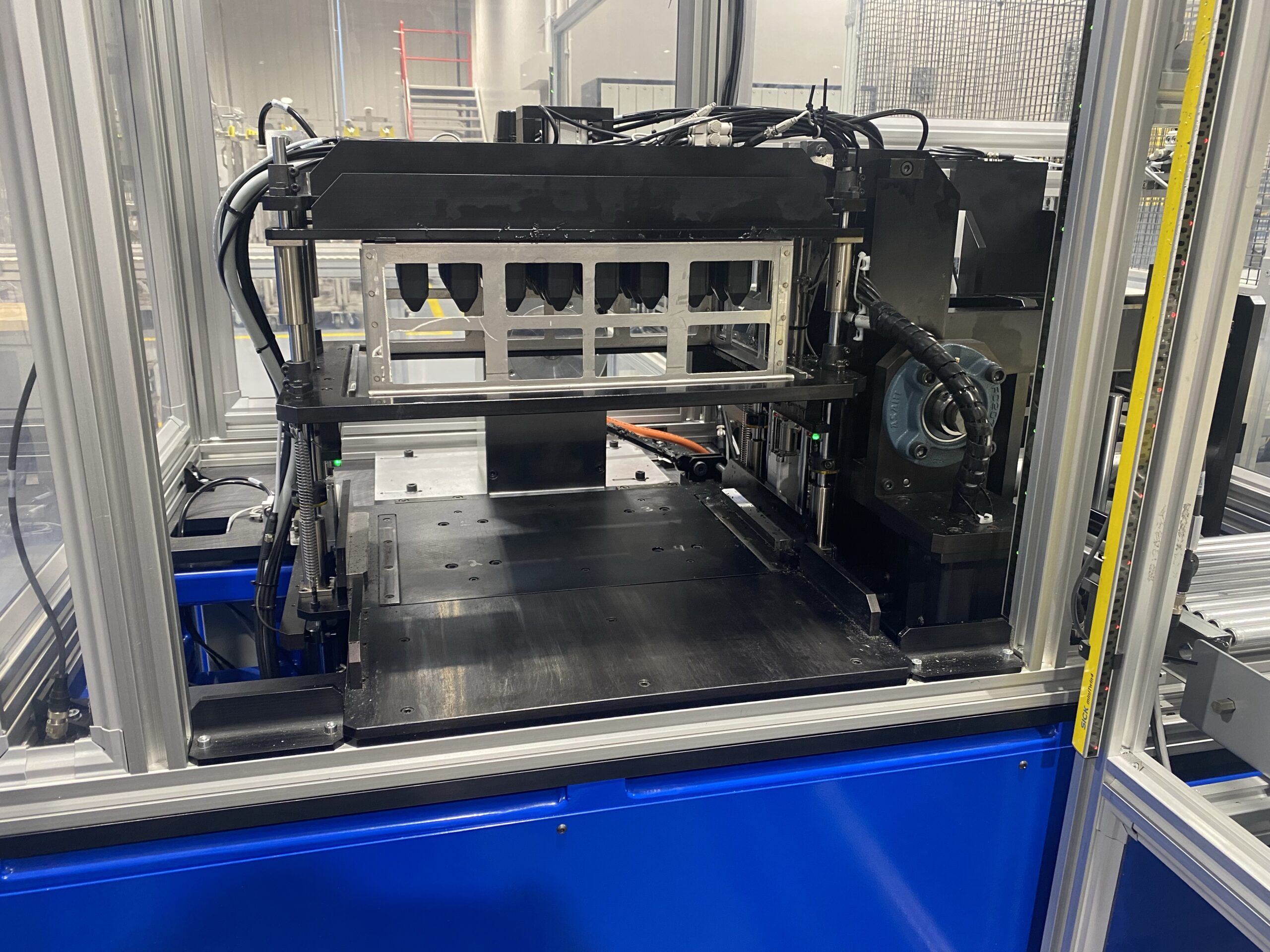

They take pre-stamped blanks from an industry partner and run them through a process which is highly automated and currently creates one magazine every eight seconds.

Initially, the stamped steel blanks are washed, with one completing the process every four seconds. This process includes wash and rinse followed by spray and tumble. They also press the blanks together and inspect them as if they were already welded into a solid body.

Next, the blanks are flipped in order to be fed into the assembly process.

I spoke with SIG Chief Operating Officer Ron Goslin about this process. He told me that at its heart SIG is an engineering company. They took a look at how magazines have traditionally been manufactured and decided to go at it from a different angle. They worked with industry partners to integrate capabilities into the magazine production line.

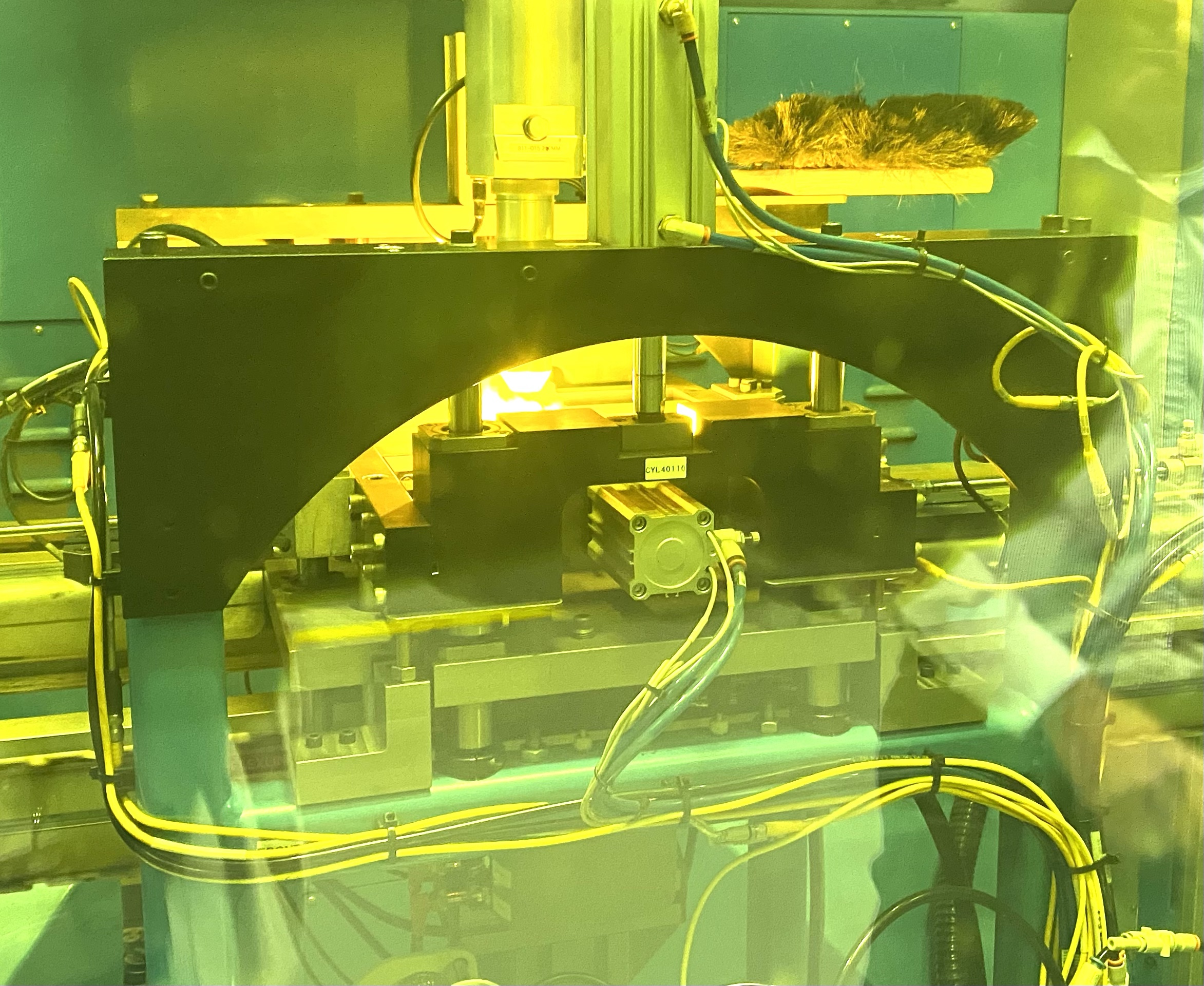

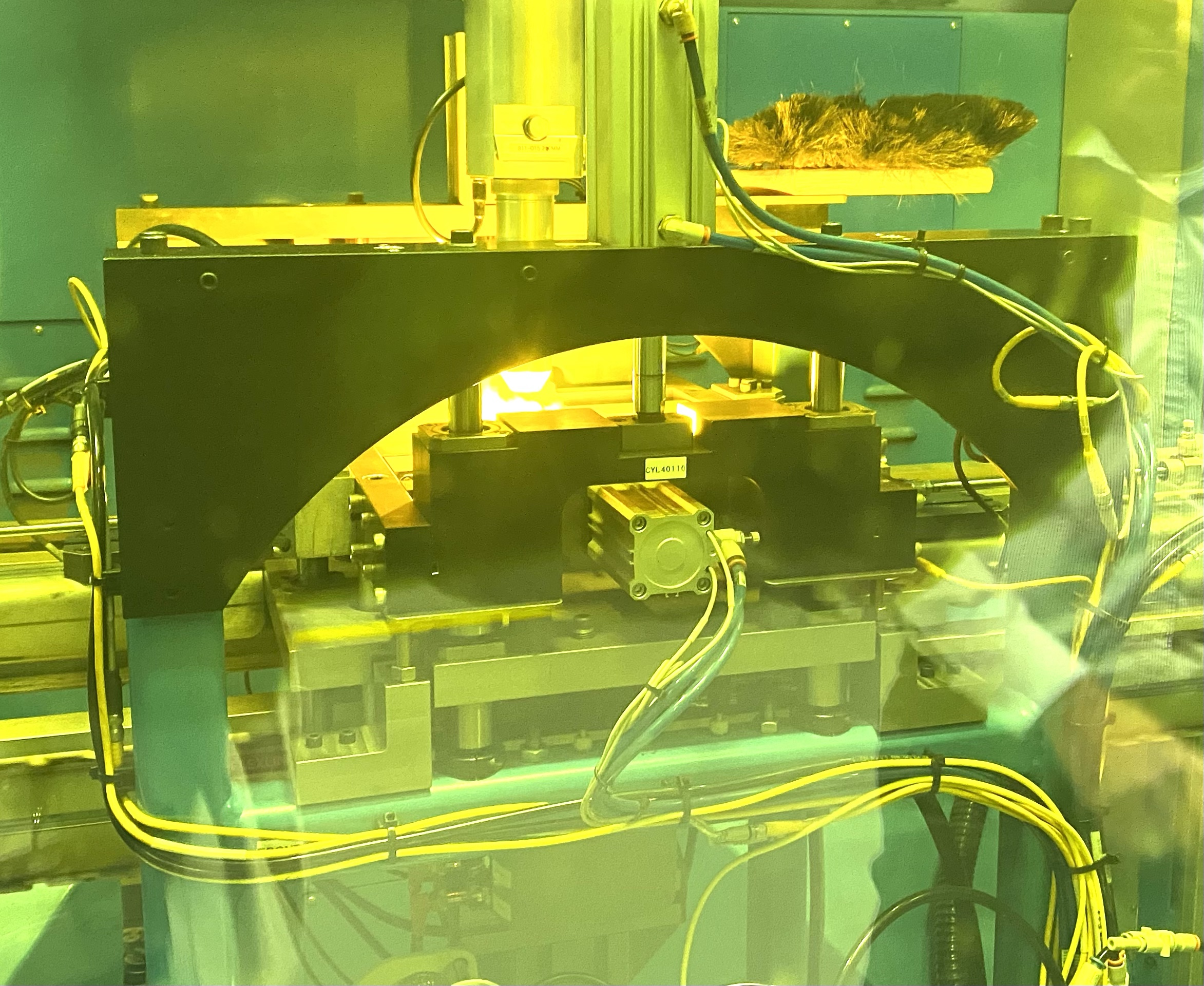

Their secret is laser welding. Traditionally, steel magazines are TIG welded with extended tabs which are removed to accommodate the puddles at the beginning of a weld. SIG VP of Manufacturing Engineering Nick Fappiano related that laser welding, combined with robotic automation to align the two sides of the stamped blank, has proven more precise and consistent.

The welded bodies are then sanded by a robot for consistency.

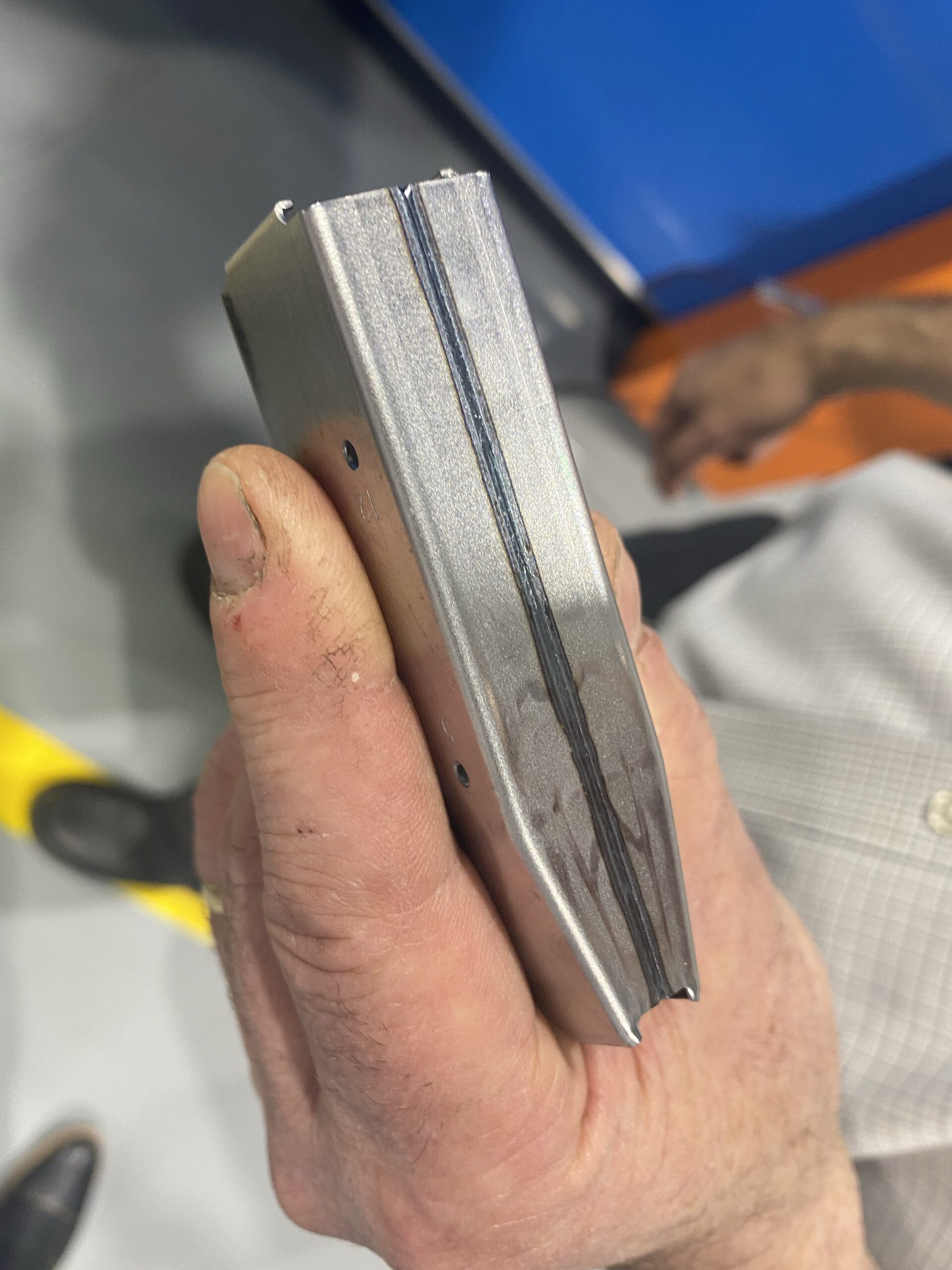

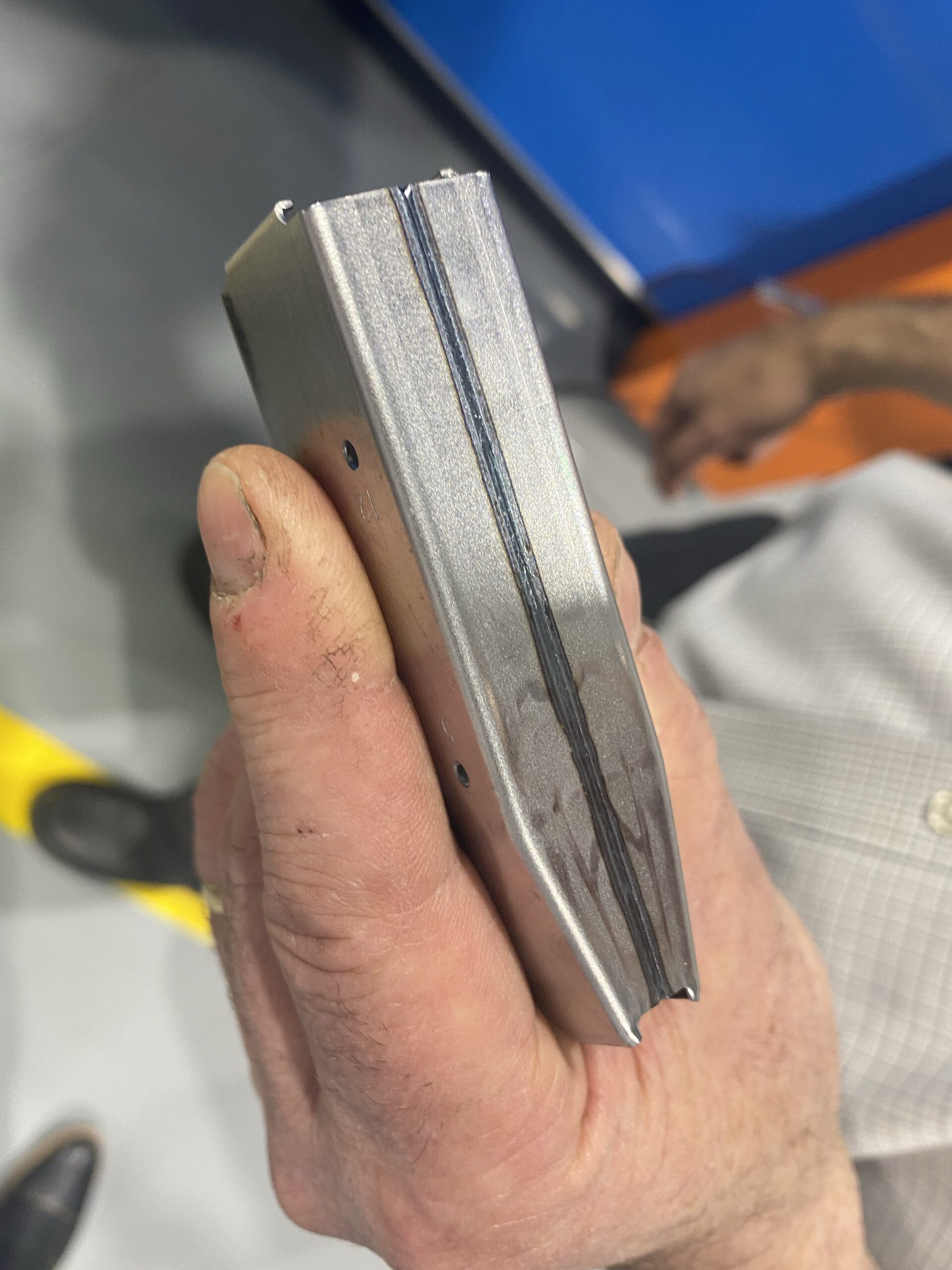

Below you can see the results, with the weld line barely visible.

The bodies are currently going out for heat treating and black oxide treatment but those capabilities will eventually migrate in-house as well.

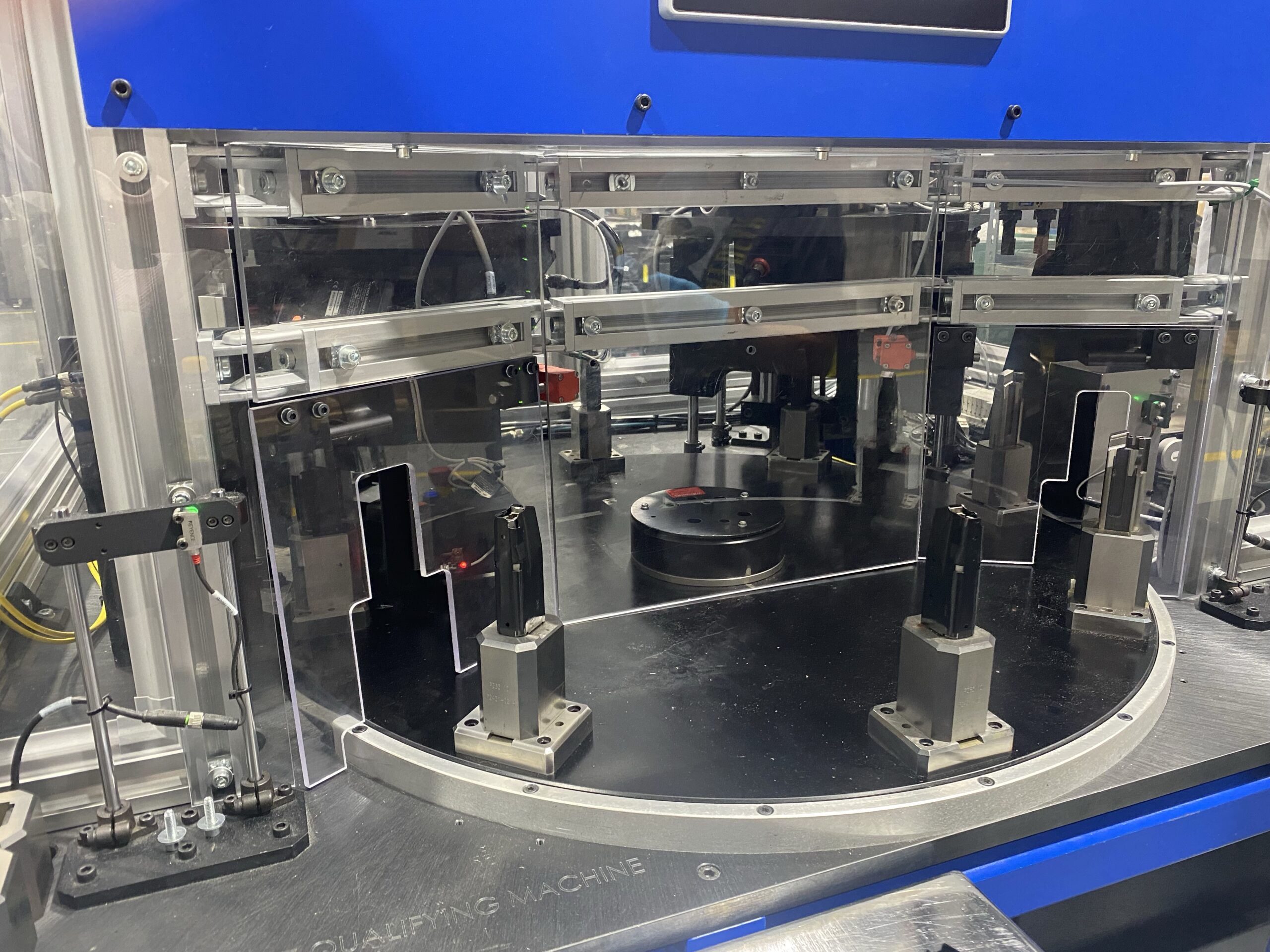

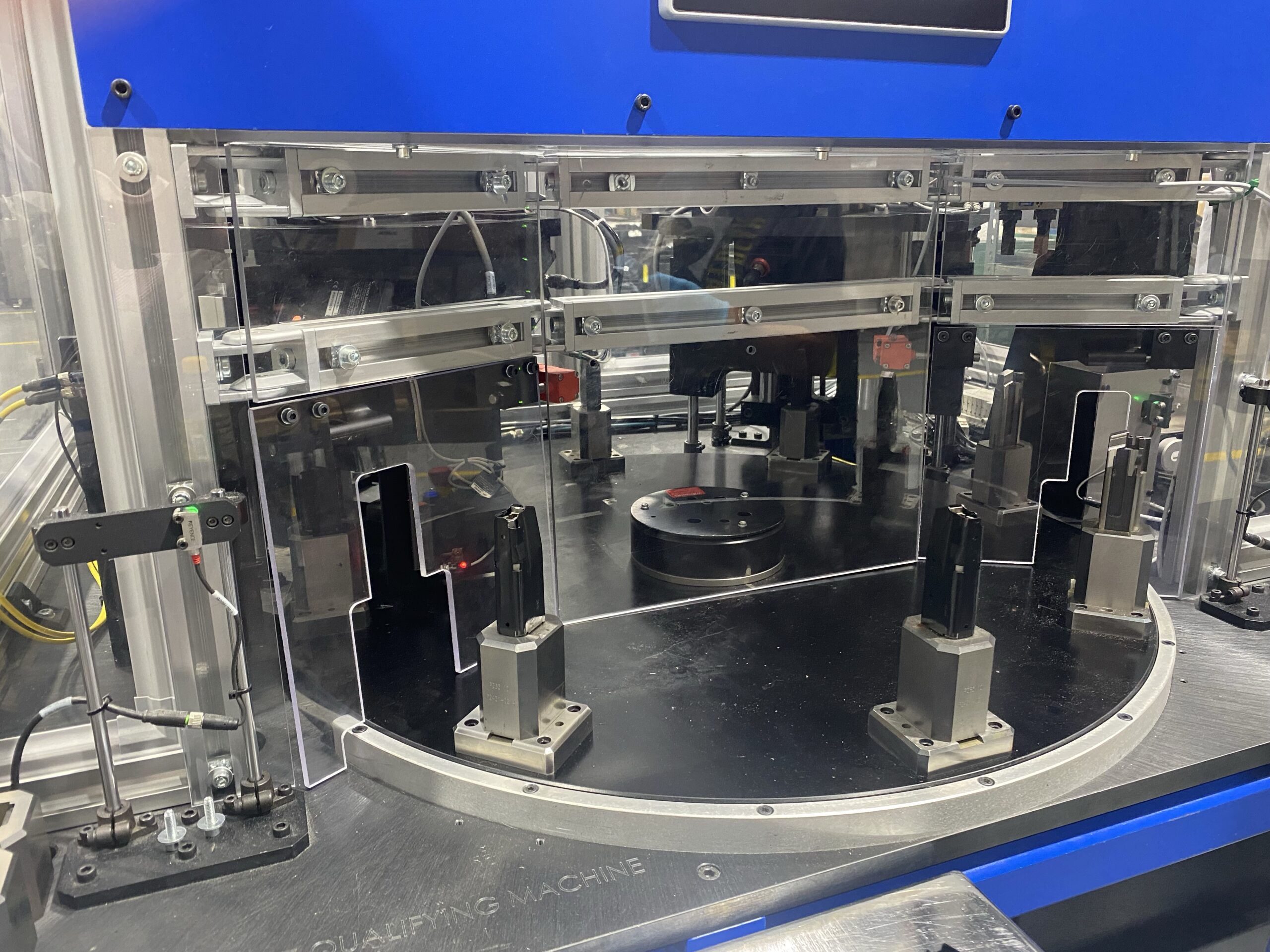

Although the bodies are gauged throughout the process, finished bodies are treated to a full going over on a rotary table with two stations looking for precision in the body’s construction. Additionally, the feed lips are formed into place with the body’s resistance taken into account during the procedure to ensure consistent feed lip alignment.

Finally, assembly with follower, spring and floor plate is accomplished by technicians, but they are already looking toward automation of this step.

In the future this assembly line will be replicated, resulting in a manufactured magazine every four seconds to match the production rate of the wash system.

Currently, the line requires six technicians. With the doubling of production capacity to two lines, that number will grow to 11; five per assembly line and one for the shared wash station.

In addition to supporting NGSW, the in-house magazine production capability could support commercial sales in the event of future supply chain shortages.