Having recently completed Production Qualification Testing of the XM7 Rifle and XM250 Automatic Rifle, the US Army has begun issuing the first of the Next Generation Weapon System to 2nd Bde, 101st Airborne Division. Of note, the famed 101st was also the first unit to receive the M17 Modular Handgun System.

The capability

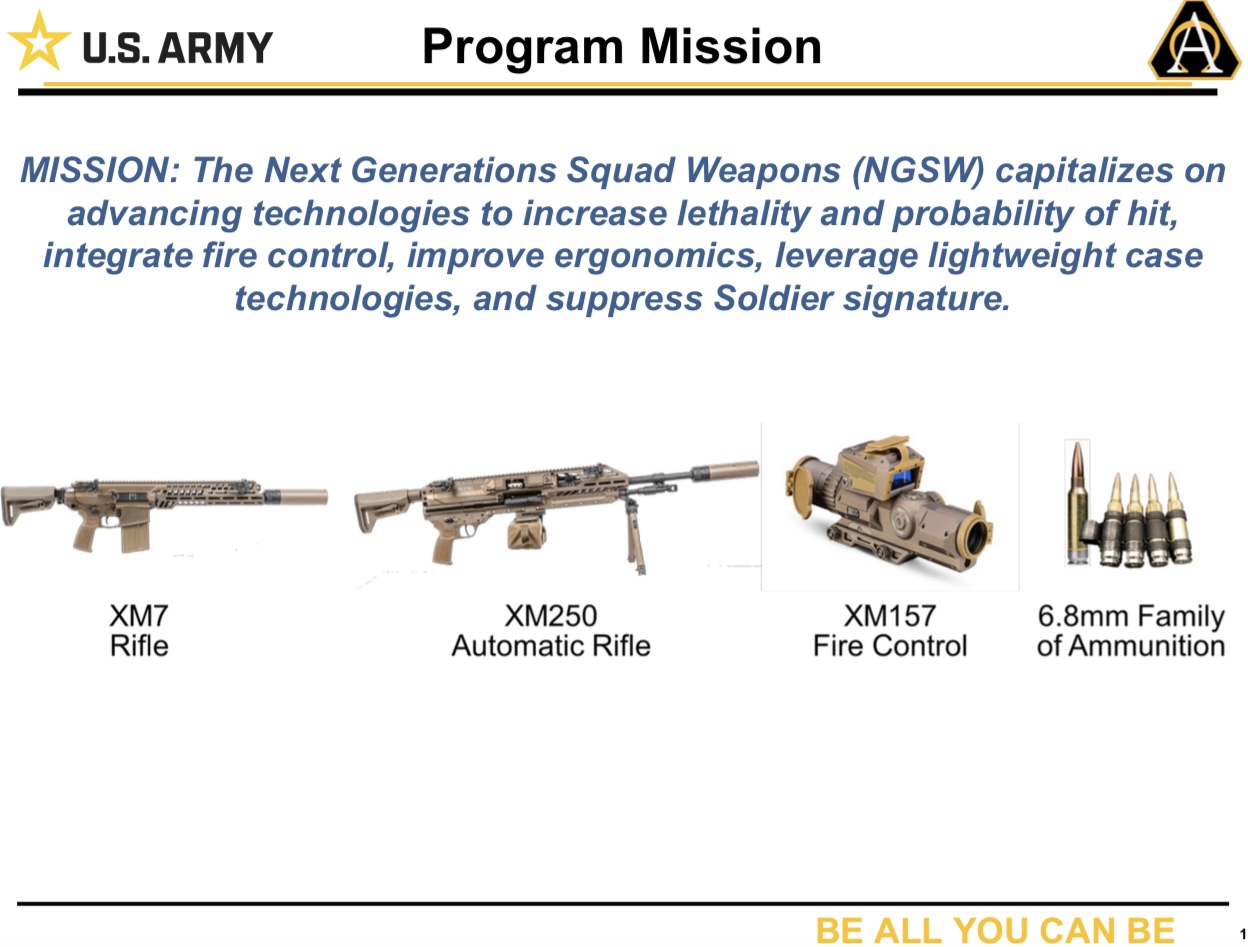

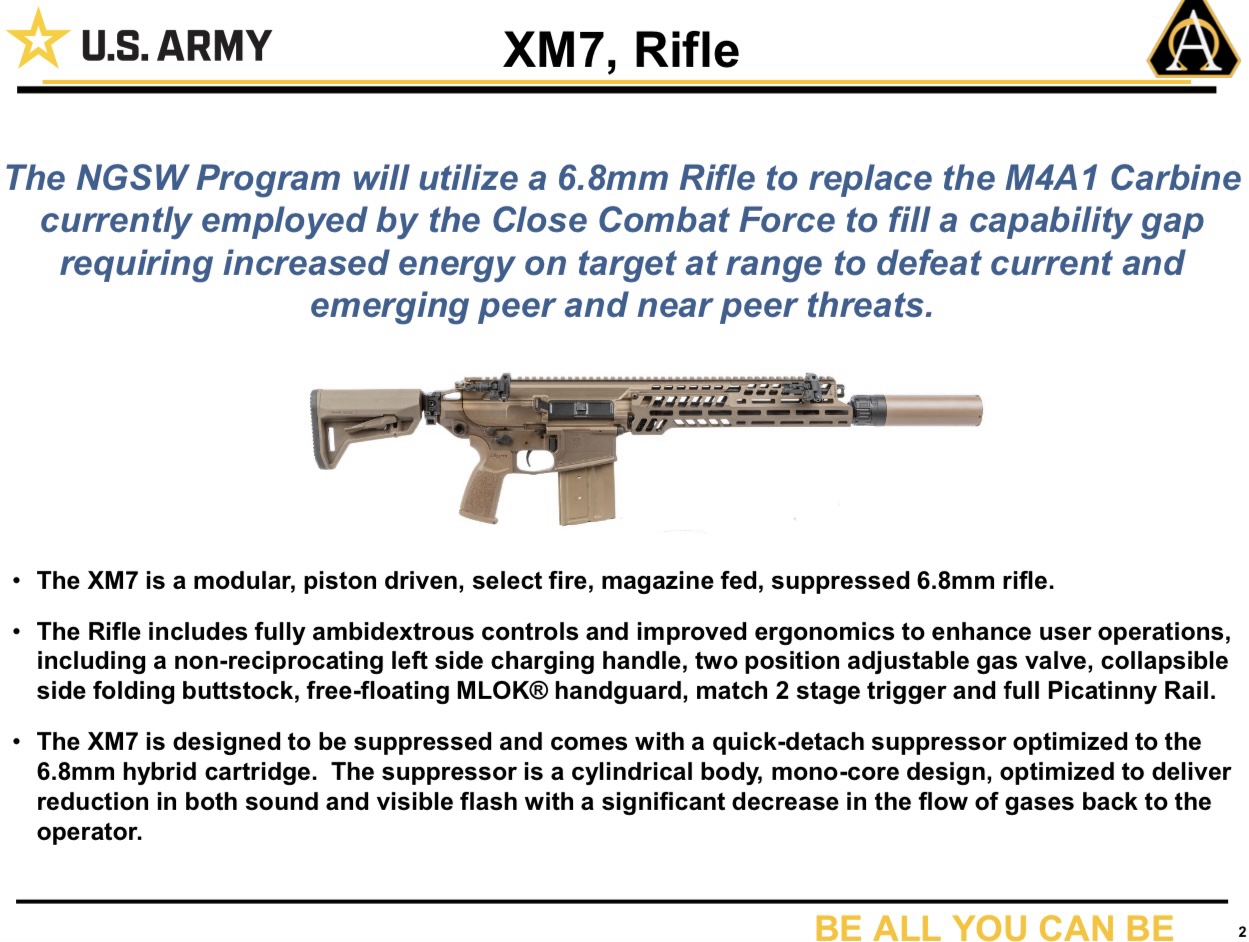

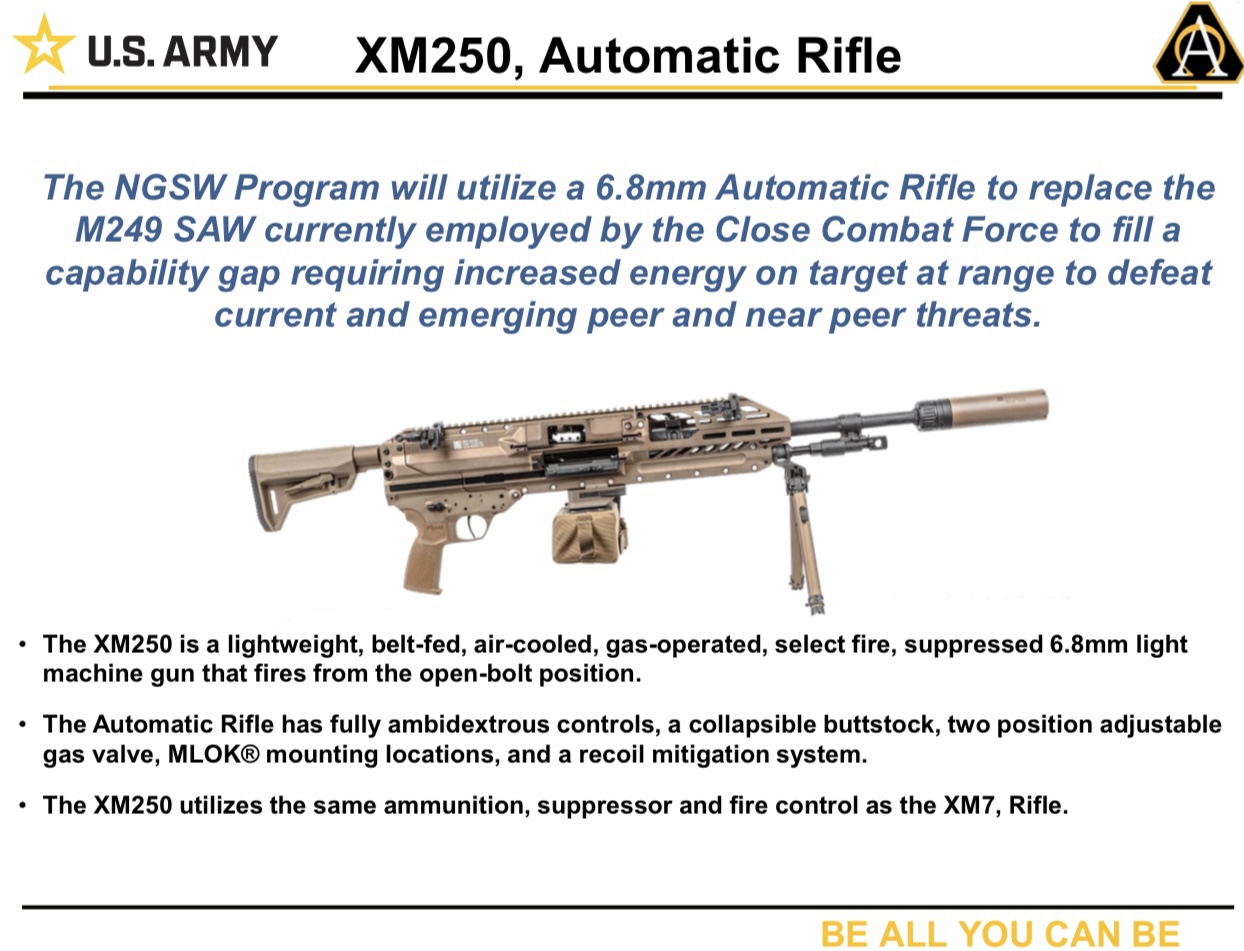

Manufactured by SIG SAUER, the NGSW consists of the two weapons along with a new hybrid cartridge in 6.8x51mm. These new weapons are being referred to by the Army as the, “most lethal small arms capability in the world” and are intended to replace the M4A1 Carbine, M249 Squad Automatic Weapon, and 5.56mm family of ammunition. But not every Soldier is getting these new weapons. They are reserved for the Close Combat Force which consists of Infantry and Cavalry Scouts as well as select Combat Engineers and enablers. All told, the Army aims to field around 100,000 XM7s and 20,000 XM250s.

XM7 Rifle

XM250 Automatic Rifle

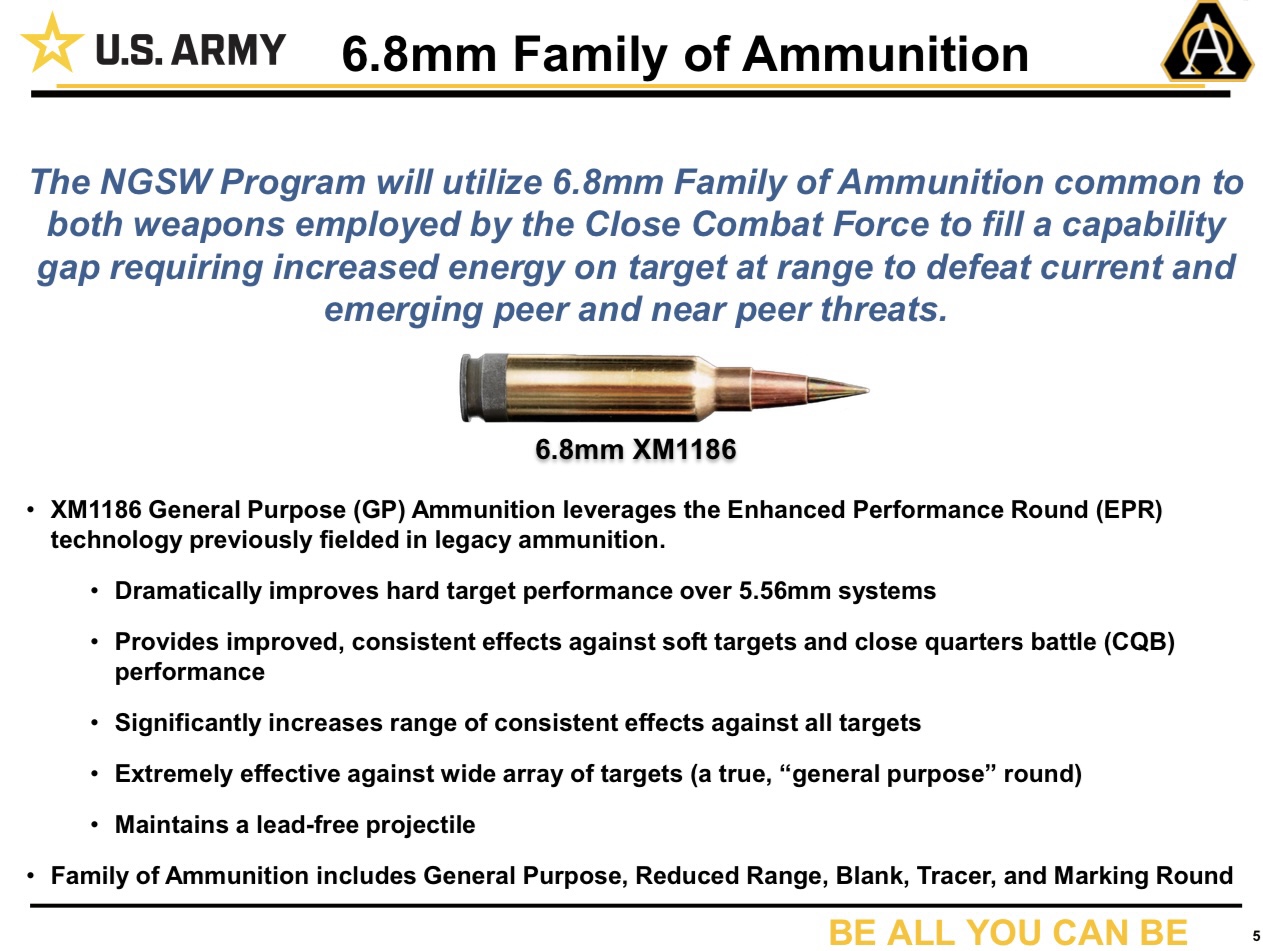

6.8mm Family of Ammunition

The Common Cartridge Family of Ammunition has similar performance to the commercially available .270 Win Short Mag cartridge and consists of the XM1186 GP ammo along with reduced range, blank, tracer, and a marking round for force-on-force training.

XM157 Fire Control

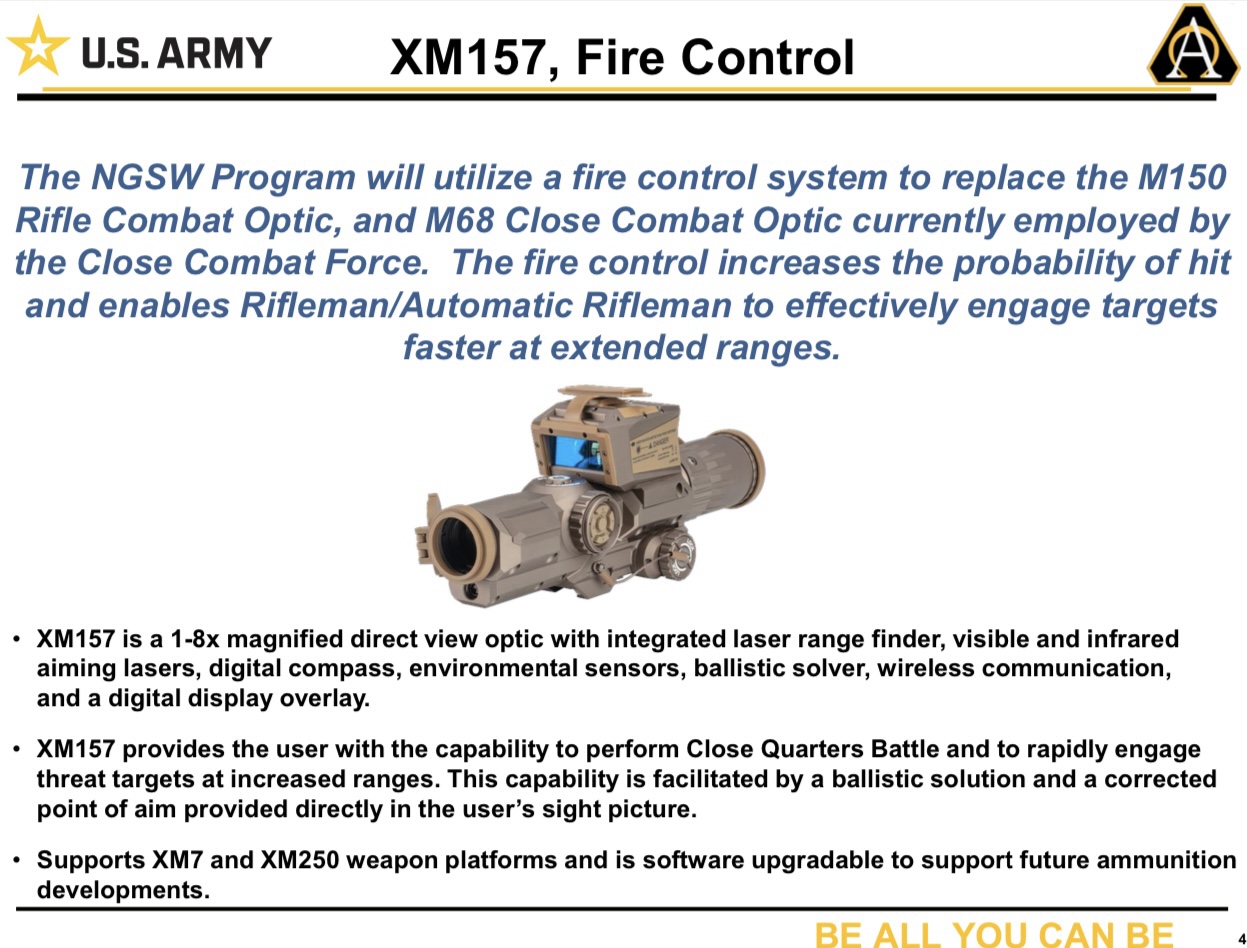

To further enhance lethality, NGSW is paired with a new Fire Control System manufactured by Vortex Optics. It integrates a number of advanced technologies including a variable magnification optic, backup etched reticle, laser rangefinder, ballistic calculator, atmospheric sensor suite, compass, Intra-Soldier Wireless, visible and infrared aiming lasers, and a digital display overlay.

The NGSW-FC is the planned replacement for the Close Combat Optic, Rifle Combat Optic, and Machine Gun Optic within the Close Combat Force.

It is important to note that the Army’s position is that Fire Control doesn’t replace training but enhances the fundamentals.

For those of you wondering, the XM157 uses two CR132 batteries and the life is 250 hours on the low setting.

Additionally, the Army has conducted integration testing between the XM157 and Integrated Visual Augmentation System in each iteration, including IVAS 1.2 which is currently in testing.

The team

To field NGSW, the Army has assembled a team of teams which include PEO Soldier, JPEO Ammunition, Close Combat Cross Functional Team and Army Test and Evaluation Command.

The road to the selection of a NGSW system was started about six years ago with a short lived quest for an Interim Combat Service Rifle in 7.62 NATO which quickly morphed into the search for 6.8mm weapons which resulted in contract award in April 2022.

SAAC Study

The Small Arms Ammunition Configuration study was published 26 June 2017 and several conclusions informed the requirement for NGSW.

They are:

-Caliber doesn’t matter

–Secondary performance driver

-Ballistic energy on target does matter

-Advanced bullet tech matters

-Fire control matters

-Aim error reduction has largest impact on performance

–Advanced fire control reduces aim error in lieu of extensive shooter experience /ability or significant training

The path ahead

On 25 Sep 2023 the A Co, 2-502nd, will go through New Equipment Training followed by a demonstration of the new capabilities of NGSW brings to the table.

Beginning 10 Oct 2023, the unit will participate in a Limited User Test which will examine Soldier mobility (timed) with both the new weapons as well as legacy systems. They will also evaluate overall system performance, how Soldiers interact with the new weapons, and how they feel about them. The NGSW team will also begin to consider how they may transform TTPs.

Additionally, a squad from the Ranger Regiment will join the members of the 101st in the LUT to gain SOF insight into the weapons.

In the coming months is environmental testing including desert, jungle and arctic and an Operational Assessment will be conducted 1st qtr 2025. This is an event designed to determine how Soldiers will fight with the new capability.

The Army plans for the 1st Bde, 101st to be the first unit equipped in 2nd Qtr, FY24, likely in March.

Turning cover into concealment

During a visit earlier today to Aberdeen Army Test Center, PM SL representatives demonstrated that the 6.8mm round will defeat cinder blocks used in the construction of buildings around the world and a barrier which the 5.56 cartridge fired by the M249 SAW will not penetrate through and through. This new capability is a huge advantage for those fighting in built up areas and against trench and bunker complexes.

As LTC Micah Rue, Product Manager Soldier Weapons, PEO Soldier put it, “NGSW turns cover into concealment.”

Ammunition production

Currently, the Army is manufacturing the 3-piece GP projectile which is based on Enhanced Performance Round technology and SIG is producing the cartridges at their factory in Arkansas.

Lake City Army Ammunition Plant will establish an interim capability in 2024 and transition to an enduring capability in 2026. All the while, SIG SAUER will continue to produce ammunition, pursuant to their contract.

The Elephant In The Room

If there’s a common criticism of the XM7 it’s the weight. Weight is certainly an issue for the Soldier and there is some good news and some not so good news when it comes to NGSW.

The raw data when comparing an M4A1 with Close Combat Optic to an XM7 fitted with the XM157 NGSW Fire Control System and suppressor sees the XM7 at three pounds heavier. However, that would be comparing apples to oranges. With the XM7 the Soldier is not only getting an Infantry Rifle capable of firing a more lethal projectile, but also a suppressor and an advanced optic which greatly increases the ability to hit targets, particularly out past 300 meters.

On the other hand, the great news with the XM250 is that it is 2.7 pounds lighter than the M249 SAW it replaces, both with 100 round belts in place. The Soldier is also getting a suppressor with the XM250 and that same 6.8mm round which will defeat cinder blocks at ranges exceeding 300 meters.

Constant improvement

As a completely new capability the program has faced some engineering challenges including toxic fumes, reliability and dispersion. However, the PM has worked with industry to quickly solve these problems and keep the program on track.

Other changes have been made to the weapons to enhance their performance. For example, SIG added an additional feed pawl to the feed tray cover which makes it easier to load a belt without lifting the cover. They also removed the forward assist from production versions of the XM7 to reduce the weight of an unneeded feature.

This is happening

NGSW is an Army modernization priority as they push forward with their fielding plan. Although there are still several events between now and First Unit Equipped, it is only six months away. This program is moving very quickly and will transform the squad in ways we are not even aware of yet.

All images and charts provided by PEO Soldier.