In 2025, the Communications-Electronics Command Software Engineering Center advanced the Army’s modernization portfolio through scalable software capabilities.

Given the Army’s adoption of continuous delivery and modern DevOps, transformation is the new normal for the Department of War support center headquartered in Aberdeen Proving Ground, Maryland.

DEVSECOPS AND CONTINUOUS DELIVERY

Powered by expertise in AI, DevSecOps, electromagnetic warfare, operational support, and software solutions, the Center concluded the year by advancing its core mission to deliver modular, transformative solutions that meet Soldiers’ evolving needs through enhanced cyber posture, scaled-up deployment cadence, modernized systems, and expanded field engagement. These competencies support enterprise DevSecOps efforts on behalf of the Enterprise Cloud Management Agency and the Chief Information Officer.

CECOM SEC’s extensive and continuous modernization posture kept the Army ahead of evolving threats without disrupting readiness. In step with its continuous software release cadence, the Center delivered 350 security updates in FY25, ensuring Soldiers have access to cutting-edge capabilities.

SOFTWARE MODERNIZATION AND CLOUD ENABLEMENT

FY25 saw the Center meet the Army’s need for cloud-based solutions. Cloud-enabled modular infrastructure allows the Army to deliver innovation rapidly so updates can be rolled out instantly across the force without delay.

“Software’s always changing, the environment’s always changing—so the requirements for systems are also changing with that, and we need to be able to adapt,” says Seiichi Sugawara, computer scientist for CECOM SEC.

The Center is propelled by the Army’s demand for innovation against the backdrop of an ever-changing battlefield.

“There’s a change in risk appetite. The Army is taking on more risk in order to release these next-generation systems faster,” Sugawara stated.

In FY25, CECOM SEC’s modernized cloud infrastructure met this speed of delivery with almost 600 software releases.

ZERO TRUST CYBERSECURITY

With the Army moving toward cloud-native solutions and continuous integration and continuous delivery, or CI/CD, there’s a growing requirement for a cyber posture that underpins modernized capabilities.

CECOM SEC advanced its cyber posture for the Army by working with the Army Materiel Command to support the DOW’s policy and procedure development for Zero Trust cybersecurity. In an escalating cyber threat environment, one of the Center’s goals is to educate the workforce on Zero Trust by partnering with Defense Acquisition University. The Center also partnered with U.S. Military Academy at West Point to analyze the feasibility of the SEC-developed mapping between Zero Trust and the DOW Risk Management Framework.

Continuous hardening of Army systems is required to ensure that readiness keeps pace with modernization across a more resilient foundation.

AI FLOW AND AI-ENABLED CAPABILITIES

FY25 was also CECOM SEC’s successful proof-of-concept year for AI Flow, an application built around AI agents, workflows, smart API’s, and custom AI applications. Designed to revolutionize workflows through cutting-edge AI technology, the application uses open AI structure to assist in a range of functions.

AI Flow currently handles 37 subscriptions with 500 agents across various organizations and averages 90 million tokens a month—and is growing, too. In FY25, the user base surged to 5,000.

The Center’s Army Reprogramming Analysis Team combined AI Flow with its Simulation Modeling Framework to create an AI-enabled code generator.

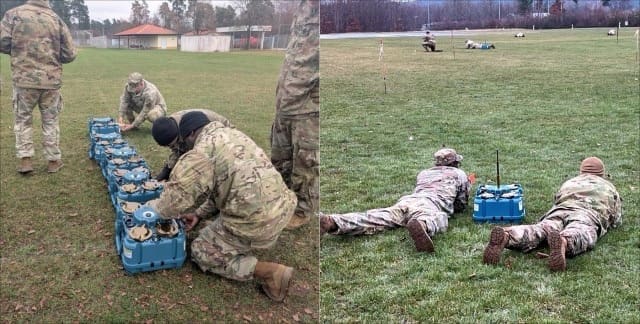

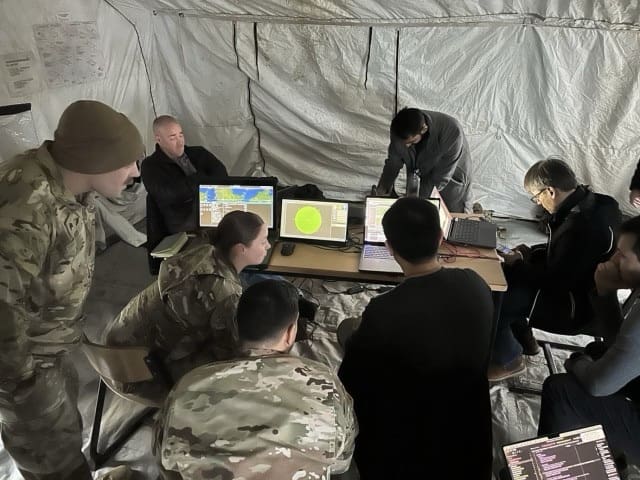

ELECTROMAGNETIC WARFARE AND THREAT ANALYSIS

That effort is part of the Army’s increased demand for threat analysis. FY25 saw continued field demand, upping the tempo of electromagnetic warfare support and driving the need for faster mission data updates. The Army Software Portal Electronic Notification System, managed by CECOM SEC, provided over 33,000 downloads for Soldiers requiring air and ground mission software support. The Center also analyzed 2,800 threats.

READINESS DATA AND DECISION SUPPORT

CECOM SEC’s mission focus in readiness continued to build rapport with Soldiers in the fight across the world. Its Data Analytics and Readiness Team developed a Power BI decision support tool that gives Army leadership real-time visuals of critical data such as budget allocations, acquisition milestones and equipment deployment timelines.

The Center’s usage of Low Code No Code technology is accelerating development and delivery of software to Soldiers.

Personnel from DART and CECOM SEC’s Technical Services Directorate also worked with the Army Audit Agency to develop tools for detecting fraudulent activities involving government-issued credit cards and the Defense Travel System. Out of 17 million Army vouchers, they were able to flag 240,000 for further review.

LOOKING AHEAD

The center’s deep commitment to meeting Soldiers’ needs is a testament to its continued pursuit of scalable software readiness.

While increased demands for AI, machine learning, and automation play out, the fact remains: CECOM SEC’s mission is to support people in the fight.

“Everything serves trust—and that trust is built on our technical competence and our work ethic, and the relationships that we can build based on that,” says John Fry, Field Support Branch Chief for CECOM SEC.

All these accomplishments reflect the greater transformation underway across the Army with CECOM SEC positioned squarely at the forefront of Army modernization in FY26.

“2025 was a strategic inflection point for the Center,” says Boomer Rizzo, Deputy Executive Director for CECOM SEC. “We’ve accelerated our shift from legacy software sustainment to agile software solutions. That shift fundamentally changes how we support Soldiers and partners moving forward in 2026.”

In alignment with the Army’s broader transformation efforts, effective January 20, 2026, CECOM SEC was redesignated as the CECOM Army Software & Innovation Center.

By Kevin Deegan