Stitching with distinction: the Army’s talented tailors

FORT MEYER, Va. — From a basic trouser hem to re-designing a famous jacket fit for a President, the tailoring team at the Logistics Readiness Center, Joint Base Myer-Henderson Hall in Fort Meyer, Virginia keeps the fabric of the Army strong, accurate and reliable for its customers.

LRC JBM-HH is one of 78 LRCs that report to the U.S. Army Sustainment Command. LRCs are essential in providing support services across the entire U.S. Army. While these support services vary in type – everything from ammunition management to food service – the tailoring team is one of the unique teams that supports our Army. LRCs have a daily, visible impact on every Soldier at their duty station and provide essential services that many take for granted. For example, many don’t likely think twice about a ceremonial uniform for a Soldier, but if they looked or fit less than perfect, it would attract attention.

The LRC JBM-HH team provides tailoring services for members of the 3rd U.S. Infantry Regiment (The Old Guard), 289th Military Police Company, Joint Task Force-National Capital Region/USA Military District of Washington staff members, and a few other senior leaders and organizations. These organizations are authorized to wear the ceremonial blue uniform and include people with titles such as Commanding General, Chief of Staff White House social aides and the Army Aide to the President and Vice President. They’ve also worked on garments for presidents and other key U.S. dignitaries. With a tailoring team of only five personnel, this wide and diverse mission keeps them consistently occupied.

Comprised of three seamstresses, a tailor, a joint lead tailor and shoe cobbler, they adeptly tailor 80-100 items weekly. Common tasks take between 30 minutes to three hours to complete, while custom pieces can take much longer.

Thanks to the proficient tailoring team, the process seamlessly unfolds for those utilizing their services. As an invaluable part of ASC, they provide a unique way for leadership to look sharp and ready for a variety of occasions.

The team manages individual orders for ceremonial uniform fittings, but they also handle other aspects of daily wear, such as shirts, trousers, overcoats, raincoats, and more.

“A saber must be measured based on the height of the individual,” explains James Risek, LRC JBM-HH director. “This ensures that we are meeting the standards of the U.S. Army and the Old Guard.”

If standards are not met and maintained, there can be inconsistencies among uniforms, taking away from the polished look that the Army is known for. There may also be differences in the uniforms based on exposure to the elements, such as excessive time in the sun.

Ceremonial uniforms for the Old Guard, for example, are composed of a heavier set of cloth material that will hold up over a longer period of time. This is particularly important for the guards of the Tomb of the Unknown Soldier, Honor Guards, and funerals.

“The precision and dedication of our talented tailors to serving the Old Guard at the Tomb of the Unknown Soldier indeed symbolize their profound commitment to honor and professionalism,” says Col. Larry Dean, commander of the 406th Army Field Support Brigade.

“The heavier uniforms maintain their appearance longer, and it reduces the dry cleaning and pressing requirements,” Risek explains. “The Old Guard Soldiers have internal press machines in each of the barracks for in between funerals or other missions. This provides them the ability to press their individual uniforms as needed.”

He adds that for any alterations, they must measure, fit and size before making any necessary follow-up adjustments and transferring to the workroom. The final product is then ready for pickup and wear.

Through thousands of stitches, some noteworthy items have been worked on over the last few years.

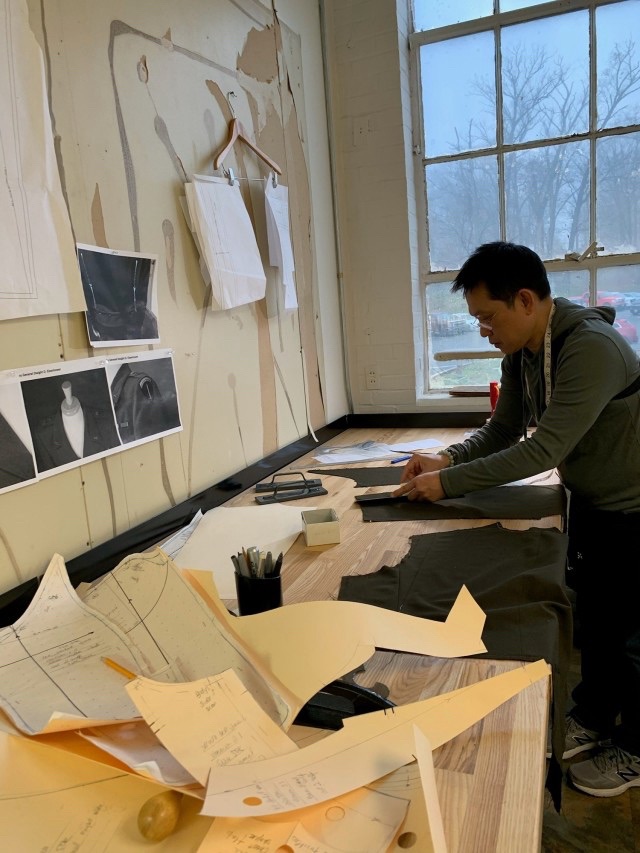

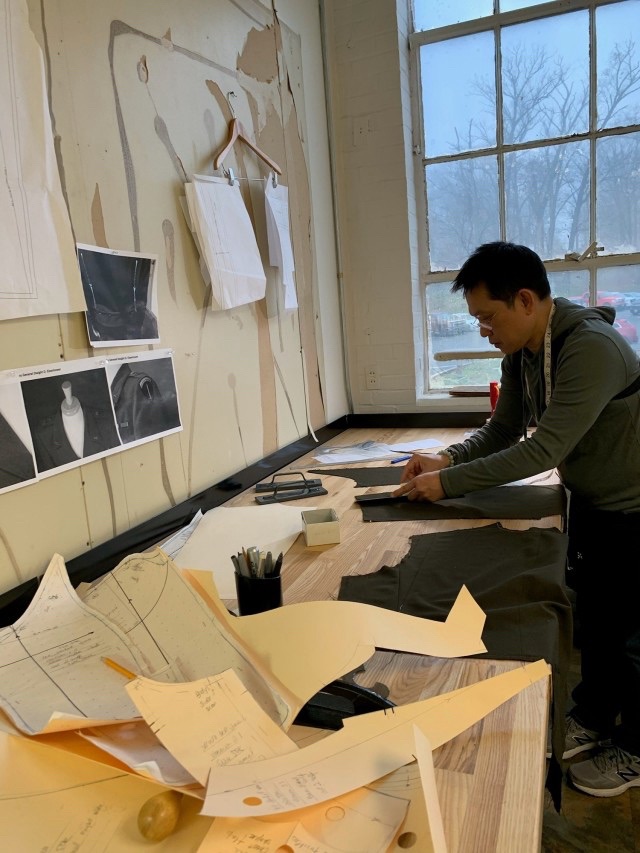

Alex Nguyen, lead tailor at JBM-HH, was invited to then chairman of the Joint Chiefs of Staff Gen. Mark Milley’s retirement ceremony this fall. Nguyen provided specialized tailoring for Milley for eight years and was specifically requested by Milley to re-outfit him as the chairman of the Joint Chiefs of Staff.

The team tailored a jacket for President Donald Trump and other key senior military leaders in 2017 for use while addressing troops overseas.

They supported the Cadet Uniform Factory at LRC West Point during a backlog, adding a new facet of uniform preparation to their repertoire.

Risek says that while most tailors and seamstresses focus on alterations, his team is different.

“The tailor shop is trained to understand the unique needs of every customer and weigh it against tailoring, embellishments and any other unique military requirements.”

The team showcased their skills and knowledge with the “Ike jacket,” designed on commission from Milley. It was the prototype of a replica of the famous jacket worn by President Dwight D. Eisenhower while in the field. This process involved using an archived jacket, relying on historical data, and applying modern standards, reviewed and approved by Milley. It was executed by the team with Milley’s input. Milley, the first fitting model for the project, made it available for Army service members to purchase and wear.

While not all items are as intricate as this project, it underscores the team’s wide range of skills and talents benefiting the Army. Whether jackets, pants, overcoats, raincoats or special commissions, most projects require at least a hem, embellishments, or final touches throughout their life cycle.

Tailors are an invaluable asset to both ASC and the Army, ensuring that military members are properly outfitted with uniforms that fit correctly and meet the standards set by the Army. While having the correct uniform is essential for a Soldier’s comfort, safety, and morale, it can also help create a sense of unity within the Army team.

By Kelly Haertjens, ASC Public Affairs