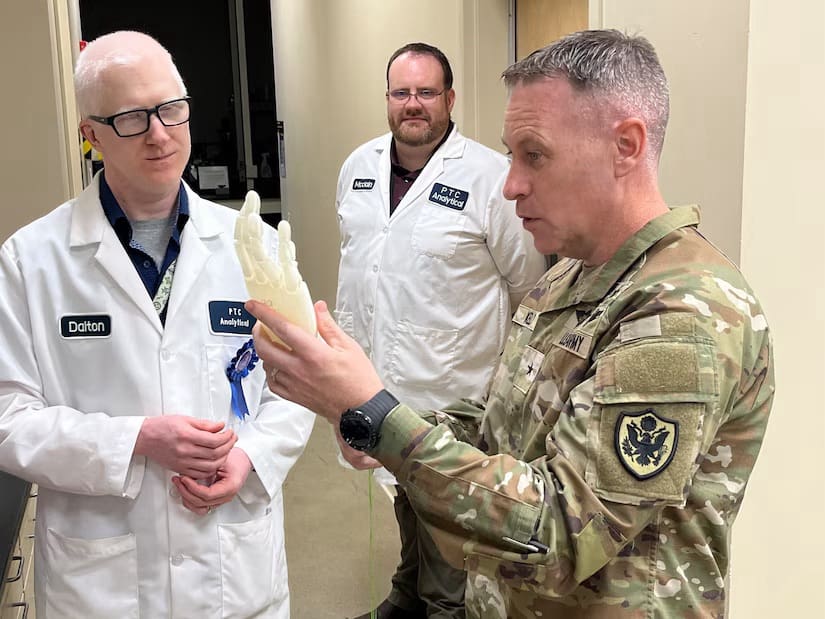

The Defense Logistics Agency Troop Support’s Product Test Center Analytical has developed an artificial hand to improve safety during glove testing.

The 3D-printed hand allows researchers to test the integrity of gloves without risking exposure to hazardous materials.

“A while back, we were asked to test some gloves that are specifically designed to protect the hands of people who work with jet fuel,” said Edward Dalton, a test center general engineer, who had the idea to create the 3D model. “One of the tests dictated that a tester put on a glove, put their hand in a bucket full of jet fuel, then flex their fingers repeatedly. If the glove leaks, it fails the test.”

The results of a failed test could be detrimental to the tester.

“A leaking glove also means the tester just got jet fuel all over their hand, which is a significant safety concern,” Dalton said. “This got me thinking that maybe we could create an artificial hand with the ability to flex its fingers. This would give us the capability of still performing the test without putting a tester at risk.”

The project, which took several months to complete, now decreases unnecessary risk situations while saving time.

According to the report, “Health Effects of Jet Fuels Used by Armed Forces,” skin exposure to jet fuels can result in symptoms such as dry skin, itching, redness, rashes, scaling, cracking, and blisters.

Mike McClain, test center supervisory chemist, has experience testing gloves using previous safety precautions that included putting plastic gloves over his hands and arms.

“I experienced firsthand failing fuel handler’s gloves,” McClain said. “Even with the efforts to protect my hand and arm, there was still some that got on me and the smell permeated through the protective plastic.”

Creating these artificial hands has given the team insights into their 3D printing flexibilities that have not been realized until now.

“The fuel handler’s gloves are specific sizes, and you must find an individual who has a hand that fits that size”, McClain said. “[Dalton] can scale the surrogate hands to match what we need for testing and adjust finger lengths to fit the design of the gloves versus the natural variation in human finger length we would normally deal with.”

Experimenting with the 3D printing options not only provides safety for the staff but also creates excitement for the possibilities this new testing method can achieve.

“I was motivated to use the tools we have access to in order to enhance the safety of our testing,” Dalton said. “Honestly, once it was all put together and I got it to work, it was really cool. I had poured a lot of effort into this, and it was very satisfying to see them finally living up to their intended purpose.”

The team conducted one experiment using the artificial hand and anticipates conducting further tests soon.

By Maurice Matthews, Defense Logistics Agency