SWEDISH COMPANY MIPS CONTINUES TO EXPAND THEIR PLATFORM, BRINGING ROTATIONAL FORCE-DAMPENING TECHNOLOGY TO HARD SHELL HELMETS IN LAW ENFORCEMENT AND THE ARMED FORCES..

MIPS, the premier brain safety technology company, has developed a new product designed especially for the ballistic helmets used by law enforcement and military personnel, as well as those in snow sports. Like all MIPS products, the core technology addresses the rotational forces that are linked to brain injuries, with the decades of research and study that went into the flagship MIPS system. This new product design, however, is refined to specifically meet the safety needs within the law enforcement and armed forces community.

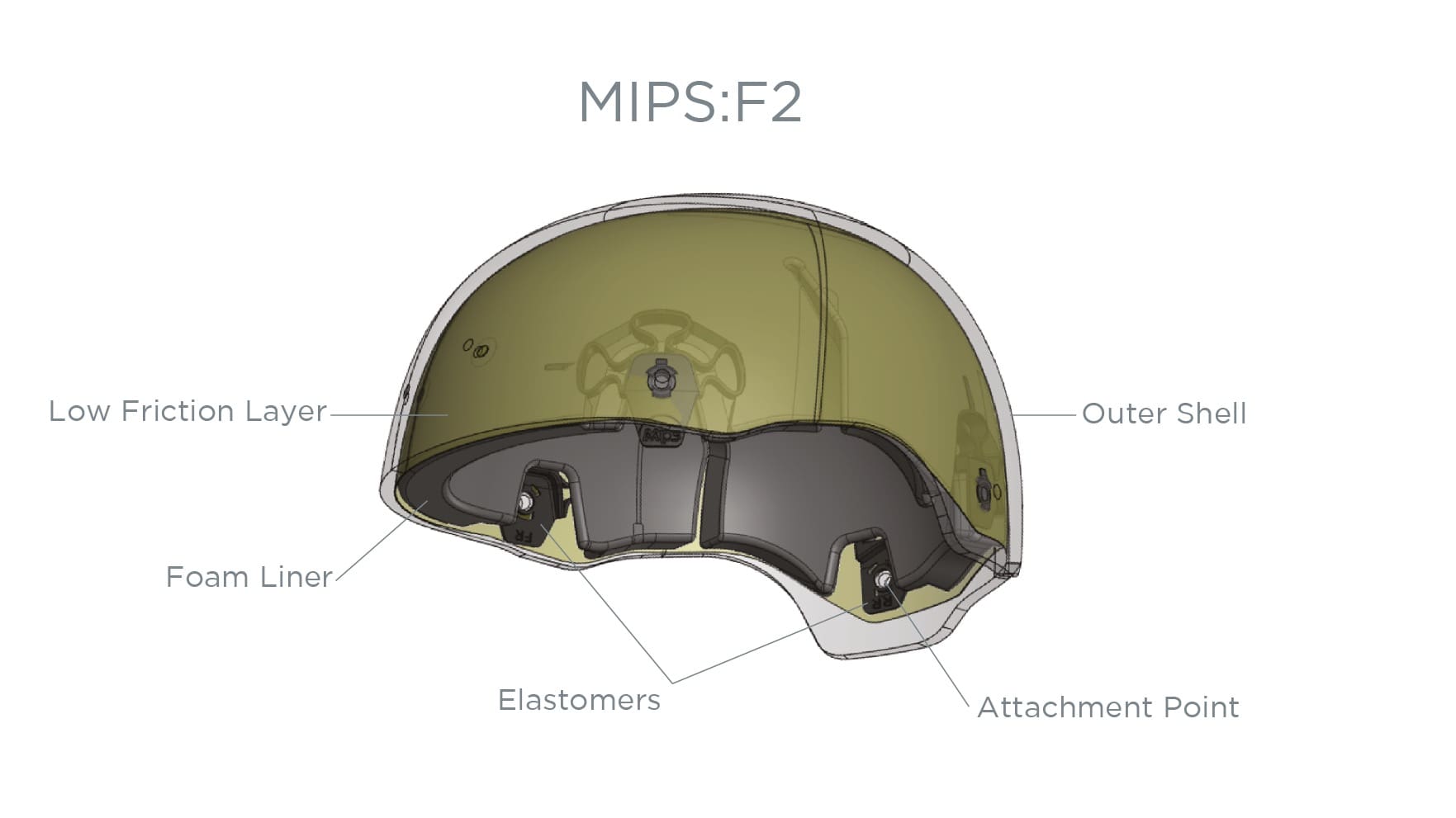

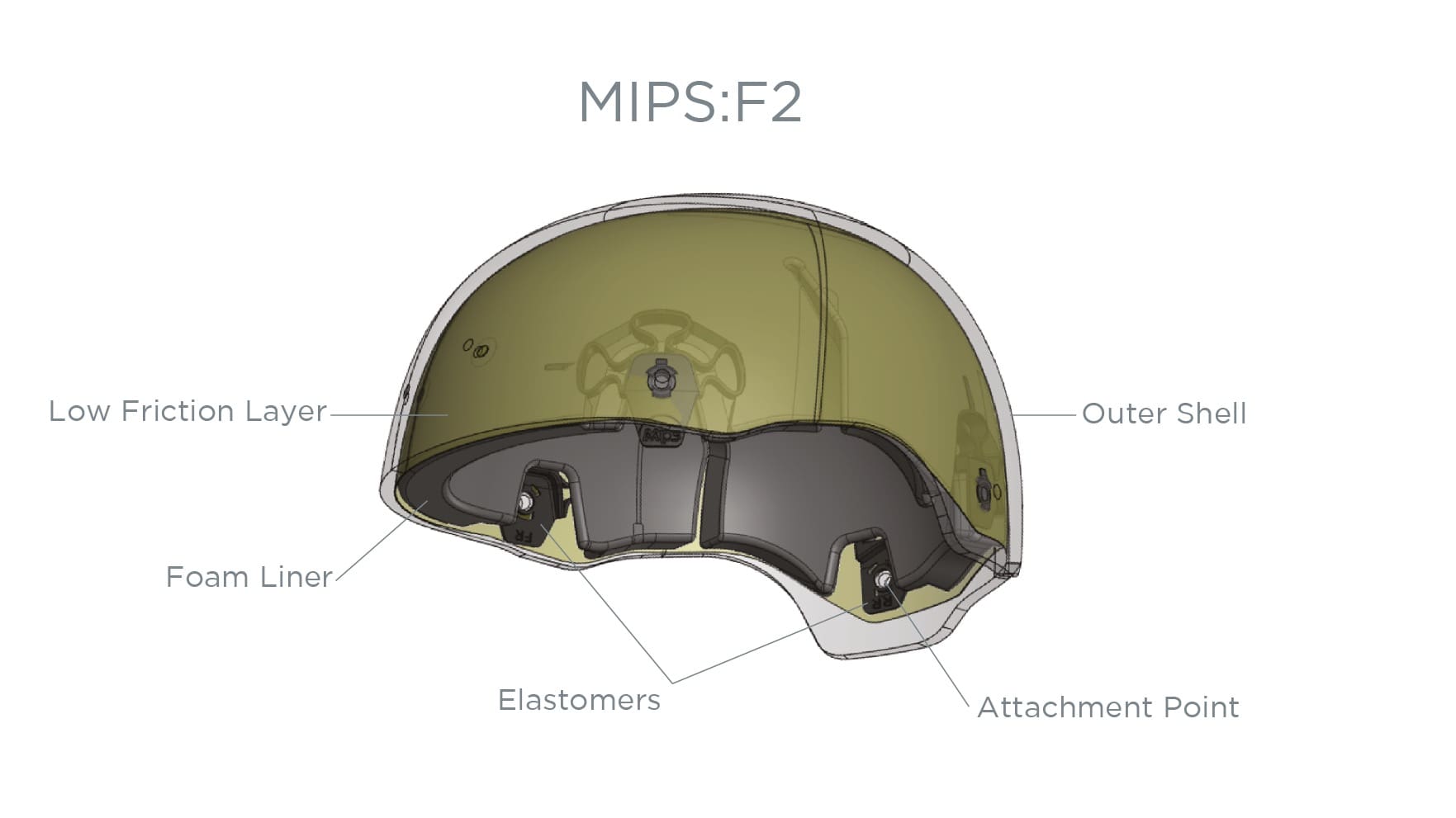

The MIPS:F2 system, is built on the standard MIPS low-friction layer that provides the crucial 10-15 millimeters of omnidirectional movement in the three to ten milliseconds following an impact. Unlike the MIPS system seen to date in active sports helmets, the low-friction layer in the MIPS:F2 is situated between the outer shell of the helmet and the foam liner on the interior. A series of Flexible Retention Organisms (elastomers) and nylon brackets that are molded into the helmet allow the foam liner to move independent of the low-friction layer and the outer shell, resulting in at least a 10% reduction in the damaging rotational motion resulting from oblique impacts.

“MIPS now has a long history helping to improve brain safety and risk of injury in the cycling and snow sports communities,” says Johan Thiel, CEO of MIPS. “With the MIPS:F2 system, we can not only expand that technology into more sports helmet models, but also we can help keep safe those who put their lives on the line to protect our communities every day.” The first helmet launched within LEAF will be SAFE4U Security of Sweden AB, a ballistic helmet model S4U SOG MIPS System. SAFE4U is a Swedish company driven by a constant desire for innovation. Development and design of protective body armour is their core business. This is done with high technology, experience, knowledge and innovation. Models featuring the MIPS:F2 will come to market in Spring of 2018.

The MIPS: F2 system is mounted between the EPP foam liner and exterior shell and provides the ability for the EPP liner to slide relative to the outer shell of the helmet. This 10 – 15 mm of relative motion is referred to as the MIPS Movement and provides added protection against rotational motion to the brain caused by angled impacts to the head.

leaf.mipsprotection.com