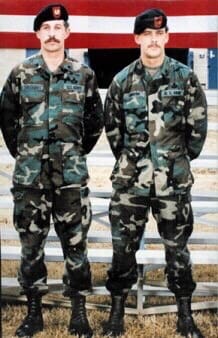

Yesterday and today October 3rd and 4th is the Day of the Rangers, Battle of Mogadishu or better known as Blackhawk Down. Task Force Ranger was tasked with conducting a raid to capture two lieutenants of a Somali warlord. Task Force Ranger was made of members of C squadron of the 1st Special Forces Group Detachment Delta and B company of 3rd Ranger Battalion, Task Force 160 Special Operation Aviation Regiment, SEALs from Naval Special Warfare Development Group and Air Force Pararescuemen and Combat Controllers from the 24th Special Tactics Squadron. They were transported to the target by ground and helicopters. The mission should have only taken about an hour. They inserted around 1350 local time, from the start they found themselves under heavy fire. When two Black Hawk helicopters were shot down (the first being around 1620 local) it quickly went from a snatch and grab to a rescue and recovery. A long ground battle to place and the U.S. forces were heavily outnumbered. By the time the last Troops made it to safety at a UN base it was around 0640 local on the 4th.

While leaving the last crash site, a group of Rangers and Delta operators led by SSG John R. Dycus realized that there wasn’t enough room in the vehicles for them and they were forced to move out on foot to a rendezvous point on National Street but they ended up going all the way back to the UN Base. This is known as the Mogadishu Mile. They think it was anywhere from 3.5 to 4 miles.

Casualties included 19 dead American soldiers and 73 wounded, with Malaysian forces suffering one death and seven wounded, and Pakistani forces suffering one death and two injuries. There were between 315 and 2,000 Somali casualties. Two Medals of Honor were posthumously awarded to MSG Gary Gordan and SFC Randy Shughart for their actions on the ground to protect one of the pilots (Mike Durant) and the crash site.

1st SFOD-D

MSG Gary Gordon Killed defending the crew of Super Six-Four Medal of Honor

SFC Randy Shughart Killed defending the crew of Super Six-Four Medal of Honor

SSG Daniel Busch Crashed on Super Six-One, died from wounds received defending the downed crew Silver Star

SFC Earl Fillmore Killed moving to the first crash site Silver Star

SFC Matt Rierson Killed on October 6, 1993 by a mortar which landed just outside the hangar Silver Star

MSG Tim “Griz” Martin Died from wounds received on the Lost Convoy Silver Star and Purple Heart

3rd Ranger Battalion, 75th Ranger Regiment

CPL Jamie Smith Died of wounds with the pinned-down force around crash site one Bronze Star with Valor Device and Oak leaf cluster, Purple Heart

SPC James Cavaco Killed on the Lost Convoy Bronze Star with Valor Device

SGT Casey Joyce Killed on the Lost Convoy Bronze Star with Valor Device

PFC Richard “Alphabet” Kowalewski Killed on the Lost Convoy Bronze Star with Valor Device

SGT Dominick Pilla Killed on Struecker’s convoy Bronze Star with Valor Device

SGT Lorenzo Ruiz Killed on the Lost Convoy Bronze Star with Valor Device

160th SOAR (Nightstalkers)

SSG William Cleveland Crew chief on Super Six-Four-killed Silver Star, Bronze Star, Air Medal with Valor Device

SSG Thomas Field Crew chief on Super Six-Four-killed Silver Star, Bronze Star, Air Medal with Valor Device

CW4 Raymond Frank Copilot of Super Six-Four-killed Silver Star, Air Medal with Valor Device

CW3 Clifton “Elvis” Wolcott Pilot of Super Six-One and died in crash Distinguished Flying Cross, Bronze Star, Air Medal with Valor Device

CW2 Donovan “Bull” Briley Copilot of Super Six-One and died in crash Distinguished Flying Cross, Bronze Star, Air Medal with Valor Device

2nd Battalion 14th Infantry Regiment, 2nd Brigade 10th Mountain Division

SGT Cornell Houston Killed on the rescue convoy Bronze Star with Valor Device, de Fleury Medal

PFC James Martin Killed on the rescue convoy Purple Heart