Phokus Research Group has introduced waterproof zippers and polyurethane construction to their Phokus Trauma Kit line.

The combination of zipper and waterproof material make this the first accessible waterproof kit (IP67) on the market. The new option will be introduced to the low viz deployment kit first, with other models to follow.

Although the cost is more, polyurethane is more durable than vinyl. Kits manufactured from vinyl will still be offered as lower cost option and in instances where high durability isn’t required such as kit components in outer containers.

Phokus Research Group products are available for agency and unit order through ADS.

When you first started diving, your instructors taught you to log all your dives. A typical entry consists of the dive location, date, time, duration of the dive, depth, water temperature, wetsuit with thickness, equipment, and other facts relevant to the dive. Like if that suit was suitable for that water temp if your foot cramped up with the fins you used and other items like that.

As we went away from diving, there are a lot of old skills and habits that have been lost. Also, as we start to use more advanced items in the water from sonar to Heads Up Dive Computers some of the necessary skills have been lost. Lastly, as we go longer durations in-between dives, it is a great idea to write stuff down, so you will remember how you had your gear set up the last time you did it. This can go for all the training that you do.

Document your number of dives. With technology today you can use your dive watch, and it does all the work for you. I think every dive company has an app that you can download your dive and add the other information you might want to remember. You will also be required to have a certain number of dives or a certain amount of a specific type of dives if you’re going to achieve different levels in the civilian dive world. Also, in most organizations, a minimum number of dives are required for you to keep your pay. If you ever have to prove you have dove, this can help.

By recording the equipment, your log can quickly become a reference to see how much weight you’ll need to descend in a given wetsuit. If you dive in various locations around the world, and in various climates, a dive log takes the guessing out of the equation. Remember to take into account what you are doing and wearing. If the last time you dove you had a 3lb sludge on your back and this time you don’t this will remind you. It never hurts to keep a paper logbook, so you can write in it and store it with your dive gear this way it is always there if needed. Lastly, write down if you had a problem with a piece of equipment. It’s easy to use something once a year and forget that you had a problem with it. Let’s say you had Nav Board that labeled as #3 and it needs to be replaced. So, when you are on deployment, and you go to dive, and you get Nav Board #3 you know to make sure it works, and it doesn’t have the same issues that it had before. Some people get very detailed in their log books others just write the necessary info down. That is up to you as long as you can look back and remember what info will help you out later. Lastly, you don’t have to use a particular book you can use anything as long as you are saving the same info.

Here is a great one, available from www.violentlittle.com/products/people-to-kill-notebook.

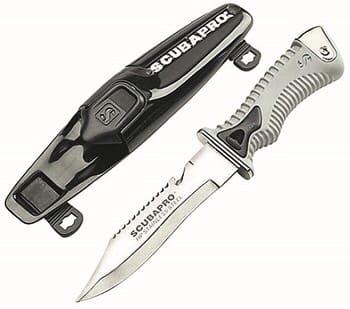

A dive knife is an indispensable tool. Offered in a variety of styles and sizes, corrosion-resistant metals and featuring a choice of cutting edges to handle different cutting tasks, a diving knife is a must-have item. A good dive knife is a must-have when you go thru underwater knife fighting school.

Dive Knife Sizes

Dive knives range from the traditional full-sized knife’s that you generally strap to your lower leg, to compact ones that can be mounted on a BCD pocket or secured to an HP hose.

The K6 is an excellent example of a traditional-style full-sized all-purpose diver’s knife. Its large six-inch blade and ergonomic grip handle comes with an injected molded sheath and two quick-adjusting buckle straps that mount easily on the lower leg.

At the other end of the spectrum is a diver knife like the White Tip. With a blade length of about 2.5 inches and an overall length of just under six inches, this type of knife is compact enough to attach to a hose or a BCD as a primary knife or to stow in an easy-to-reach pocket as a back-up cutting tool.

Diving Knife Materials

Stainless Steel Diving Knives

Stainless steel is the most common alloy used in the manufacturing of dive knife blades. The majority of dive knives are made of either Grade 304 stainless steel or Marine Grade 316 stainless steel.

Grade 304 hard-tempered stainless steel is a very versatile metal that is used in a variety of outdoor applications. It offers resistance to surface oxidation and provides an excellent cutting edge. Because it is a little softer than Marine-Grade 316 stainless steel, a Grade 304 blade needs to be sharpened more frequently to maintain its right cutting edge. The stainless steel version of the Mako is an excellent example of a diving knife made with Grade 304 stainless steel. Marine Grade 316 stainless steel is similar to Grade 304, but it has one crucial extra ingredient: molybdenum. This is a hard, silver-white metallic element used to toughen the steel. This enables Marine Grade 316 dive knives to maintain their super-sharp edges for longer periods, plus it increases corrosion-resistance. SCUBAPRO’s premier dive knife, the TK 15, offers a six-inch Marine Grade 316 stainless steel blade. The blade surface is polished explicitly so that water can drain quickly to prevent oxidation further. Also, the thickness of the knife’s stainless steel is consistent from one end to the other, creating a high level of stiffness and strength.

Titanium Diving Knives

Another popular material for dive knife blades is hardened titanium. A titanium dive knife blade is entirely corrosion-resistant, it is lightweight yet extremely strong, and it can hold a sharp edge for a long, long time, all of which make titanium dive knives excellent cutting tools for use in saltwater environments. The lightweight, multi-function X-Cut titanium dive knife is an excellent example of a titanium cutting tool. Measuring just over five inches in overall length, its 2.5-inch blade is specially designed to maintain a highly-durable cutting edge for a long life of corrosion-free performance.

Diver’s Knife Cutting Edges, Tips and More

Dive knife blades come with either a plain edge, a serrated edge or a combination of both to handle a variety of cutting jobs.

A plain edge is good for making clean slicing cuts, or when using more of a pushing motion when control and accuracy are required – like filleting a fish. This type of cutting motion is especially useful if the cutting edge is curved. Plain edges are also easy to maintain. Anyone with a basic sharpening tool can keep a plain edge razor sharp with little effort.

A serrated edge has a series of mini-edges or teeth similar to a hand saw. A serrated edge is excellent for sawing-type cuts through heavy materials like wood or rope or stubborn kelp fronds. For example, using a plain edge it would take forever to cut through a three-quarter inch anchor line, but a serrated edge would make quick work of it as the teeth bite deep into the material with every sawing motion. A serrated edge also stays sharp for much longer than a plain edge, but it is a bit more difficult to sharpen.

Because these different blade edges excel in cutting different types of materials, most dive knives offer both, often on the same cutting plane. Normally, the plain edge can be found closer to the tip of the blade, beneath the curve or “belly” of the blade, whereas the serrated portion can be found closer to the handle for better leverage when leaning into the tougher cuts.

Since a scuba diver’s knife blade’s cutting efficiency increases in relation to its length, dive knives that sport long blades, like the TK15 and K6, separate their cutting edges, devoting the entire top length of the blade to serration, and the entire bottom length to the plain edge. This maximizes the length of each cutting edge and the overall efficiency of the knife.

When it comes to blade tips, dive knives normally come with either a blunt tip, a tanto tip, or some variation of a pointed tip.

On one end of the spectrum is the blunt tip. As its name implies, the blunt tip is flat and dulled. It is designed to be more of a prying tip than a piercing tip. It is considered safer than other tips because you can’t accidentally stab your leg or puncture your BCD when returning it to its sheath.

On the other end of the spectrum is the pointed tip. These tips come in a variety of shapes. For example, the TK15 comes with a drop-point tip. This is where the blade’s upper edge, or spine, gradually “drops” as it reaches the tip of the blade to form the tip. This is considered a strong tip that is easy to control when cutting or piercing.

The K6 and X-Cut have clip-point tips, so-named because the spine of the blade is “clipped” as it approaches the tip. This creates a narrow tip that can be very useful for piercing a line wrapped tightly around a boat propeller in preparation for a slicing or sawing cut. While not quite as strong as the drop-point, the clip-point is considered a very sharp and controllable point.

Falling in between the blunt tip and pointed tip is the tanto tip. Combining elements of blunt and pointed, the typical tanto tip offers more of an angled tip which is sharpened for cutting, like on the Mako. However, sometimes the tanto tip provides a small blunt spot as well as you’ll find on the White Tip. Both versions produce a very strong and durable tip, enabling you to do a little prying with less chance of snapping the tip, with the added ability do some cutting when working in tight spaces.

Most dive knife blades also include a notch for cutting fishing line and, depending on design, and you can sometimes find additional tools like a bottle opener (Mako), a stainless steel handle-end for hammering (K6) or a shackle key (TK15).

Unique Cutting Tools You Won’t Want to Overlook

Not all scuba cutting tools look like a dive knife. Take, for example, the innovative stainless steel Mesh Cutter. While traditional dive knives are most effective when used with a pushing motion, the Mesh Cutter is designed to be used with a pulling motion. This is a safer motion, plus it provides great leverage and lots of cutting power with minimal effort. The ultra-sharp hooked blade is ideally shaped for slicing through line and netting.

What’s the Best Dive Knive?

Like with most types of dive equipment, the ideal knife depends on your individual diving style, and how you like to carry your gear. The choices are many. The good news is that with the variety of dive knives available in different sizes, shapes, materials and mounting options, finding the best dive knife to suit your unique diving needs shouldn’t be too difficult.

On 30 April,1798 Congress establishes the Department of the Navy as a separate cabinet department. Previously, naval matters were under the cognizance of the War Department. (I like the name War Department better then Department of Defense) Benjamin Stoddert is named as the first Secretary of the Navy.

United States Navy claims 13 October 1775 as the date of its official establishment, when the Second Continental Congress passed a resolution creating the Continental Navy. But with the end of the American Revolutionary War, the Continental Navy was disbanded. Then with threats to American merchant shipping by Barbary pirates from four North African States, in the Mediterranean, President George Washington signed the Naval Act of 1794 the act authorizing the construction of the Navy’s first six frigates ? Congress passed a resolution to establish with haste a national navy that could protect U.S. commercial vessels from attacks by Barbary pirates in the Mediterranean and nearby Atlantic waters. The Algerian and Tunisian pirates joined forces, and by 1650 more than 30,000 of their captives were imprisoned in Algiers alone. Piracy was the cause of several wars between Tripolitania and the United States in the 19th century.

New for 2019, the SCUBAPRO Go Sport fin is an update of the Tester’s Choice-winning Go fin model that impressed SCUBALab divers in 2017. The compact-but-powerful Monprene® blade with rail-mounted power bars is mated to the revised Ergo3 foot pocket that’s been re-engineered for use with booties. Interchangeable skegs, minimize sideslip and maximize stability.

The new SCUBAPRO Go Sport Fin is designed for traveling. Lightweight, comfortable, durable, and a fast and nimble performer, the Go is the ideal fin for divers, snorkelers and swimmers that travel a lot or have to carry your fins for work.

Lightweight: When it comes to premium fins, nothing compares to the Go when integrating high quality with lightweight. This translates into convenience and weight savings on the road, and comfort and ease of use in the water.

Super Comfortable: The Go Sport design combines the fitment benefits of an open heel fin. The replaceable self-adjusting bungee heel strap allows for a versatile fit — one diver can wear multiple sizes. The strap also makes it easy to don and doff the fin, and it fits comfortably against a booted heel.

Ultra-Durable: While extremely comfortable, the Go Sport is also virtually indestructible. Its durable 100% Monprene construction avoids the problems of de-lamination, broken blades and torn foot pockets that tend to plague average thermoplastic fins. This enables the Go Sport to stand up to long-term, heavy-duty use.

High Performance: The Go fin excels in strength, comfort, and convenience, but where it shines is in kicking performance. The Go is built with a 25° pre-angled blade with a central power panel that provides longitudinal rigidity and creates a channeling effect. Power bars on the underside of the rails prevent over-flex; this helps maintain the optimum angle of attack under high load conditions. The result: you get a lightweight fin that delivers speed, power, stability, and maneuverability with a minimum of effort.

They pack exceptionally well due to an innovative piggyback stack system. An interlocking tooth on one fin blade hooks into the second fin, then the bungee strap from the second fin hooks the heel of the first fin into place. It’s a snug pairing that makes packing easier. The perfect addition to the SCUBAPRO fin range, the Go Sport dedicated travel fin is lightweight, comfortable and virtually indestructible. The Go Sport Fins are available in multiple sizes. Sizing profile is the same as the Seawing Nova

I first used these fins for the first time last summer. It was for a drift dive, and I didn’t think they would be able to push my fat-a$$ around. I am 6’.2” and 225lbs. I have used the Go fins for surface swimming and love them. However, I have never tried using them diving. I was amazed at how well these fins work. They are my go-to fin now for everything I do. I can’t say enough good things about them.