As automated technology rapidly integrates into daily life, its impact on modern warfare is profound. Military divisions worldwide are deploying AI on the battlefield for defence, attack and reconnaissance. In a recent summit held in the Netherlands, 80 nations met to discuss the ethical and operational use of AI in military applications. More than 60 countries agreed to permit AI-driven combat strategies, recognising its potential to enhance decision-making and reduce human risk. Here, Taylor Eisenhauer, product manager at connector specialist PEI-Genesis explains the pros and cons of using AI in military operations.

The adoption of AI in defence is accelerating, with global military AI market projections expected to reach US$18.558 billion by 2029, up from US$4.956 billion in 2024, driven by advancements in machine learning, robotics, and autonomous systems. The deployment of AI-driven combat vehicles, drones, and robotic units is revolutionising modern warfare, reducing reliance on human personnel in high-risk environments.

However, certain issues remain regarding the advantages and concerns of employing AI on the battlefield. While AI offers enhanced strategic decision-making and operational efficiency, it also introduces significant ethical and security dilemmas.

Pros:

The use of AI in advanced military software and technologies can provide safety to soldiers, reduce human labour, and improve decision-making.

In terms of safety, humans can delegate dangerous tasks to non-human agents to protect themselves. For example, tactical ground robots can navigate terrains and handle explosives that can potentially harm personnel in combat. At the same time, robotic dogs can be utilised as an extra hand to carry or fetch necessary equipment. Using robots can save many human lives since these tasks can be performed without harming soldiers.

The United States believes that AI can reduce risks for soldiers by reducing human labour. War can put significant stress on the human body, and soldiers can become fatigued, impairing their ability to focus and perform effectively. This can lead to human error, harm mission success, and result in significant injuries or even defeat.

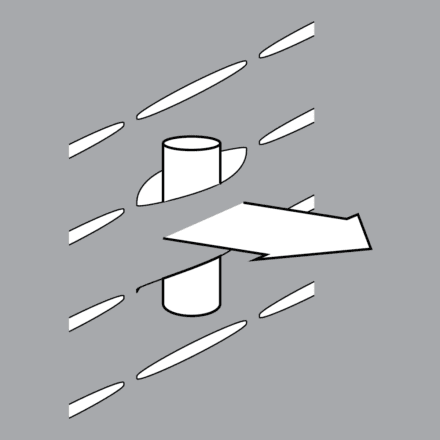

However, with AI, soldiers can utilise their time and energy better. For instance, rather than driving combat vehicles or flying aircraft, AI can take complete control and allow soldiers to focus their efforts elsewhere, such as analysing data and prepping for battle. This can significantly reduce the risk of injury and increase the chances of mission success.

Improved decision-making is another benefit of using AI. More accurate data analysis can help better target opponents. With automated technology, we can make smarter and safer decisions in combat with little to no mistakes. Drones and AI are utilised to identify and communicate risks or threats that may occur. They can more accurately determine objects in the distance, providing an advantage in preparing for an attack.

Cons:

On the other hand, some see AI as a setback or disadvantage due to the potential risks and dangers that can arise when trusting technology.

Security threats are a major concern with AI. There is a potential for AI to be hacked or manipulated by adversaries. If these systems are compromised, sensitive information can be stolen and exploited to the opposing team’s advantage.

The use of automated technology and AI, particularly in military robots, is a topic that sparks ethical concerns. With robots capable of performing tasks more efficiently and precisely than humans, there is a potential for one side to have an unfair advantage, leading to the replacement of human soldiers with machines. The result of this could be a future where wars are fought between robots, raising ethical questions about the morality of warfare.

Another issue arising from the use of AI is its unpredictability. If something goes wrong, it can be difficult to determine who is responsible. This concern becomes more significant as AI technologies become more advanced, with the potential to carry out tasks autonomously. If AI were to malfunction, innocent civilians could be harmed, and it is unclear who would be held accountable. Furthermore, granting machines a mind of their own may lead to unforeseen consequences; therefore, we must approach the development and deployment of these technologies with caution.

Prepare for the future of modern warfare

The debate about allowing AI to be used in modern warfare is endless. However, the reality is that AI is being implemented in military technologies worldwide, and nations must be equipped to protect and defend themselves.

To prepare for modern warfare, durable and reliable electrical connectors are needed to support these advanced technologies in harsh environments—PEI-Genesis partners with industry-leading suppliers to provide a broad inventory of products suitable for these demands.

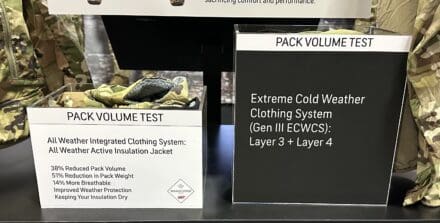

For example, the Amphenol 2M Series of lightweight, micro-miniature circular connectors maximise SWaP (size, weight, and power) and meet D38999 specifications for vibration and shielding but weigh less than standard D38999 connectors. Whether this product is for a soldier’s headset, tactical or handheld equipment, airframes, or avionics boxes, the Amphenol 2M Series has application flexibility with multiple coupling types available to fit different electrical and mechanical requirements.

To find out more about the wide range of connectors for military operations offered by PEI-Genesis, visit www.peigenesis.com.