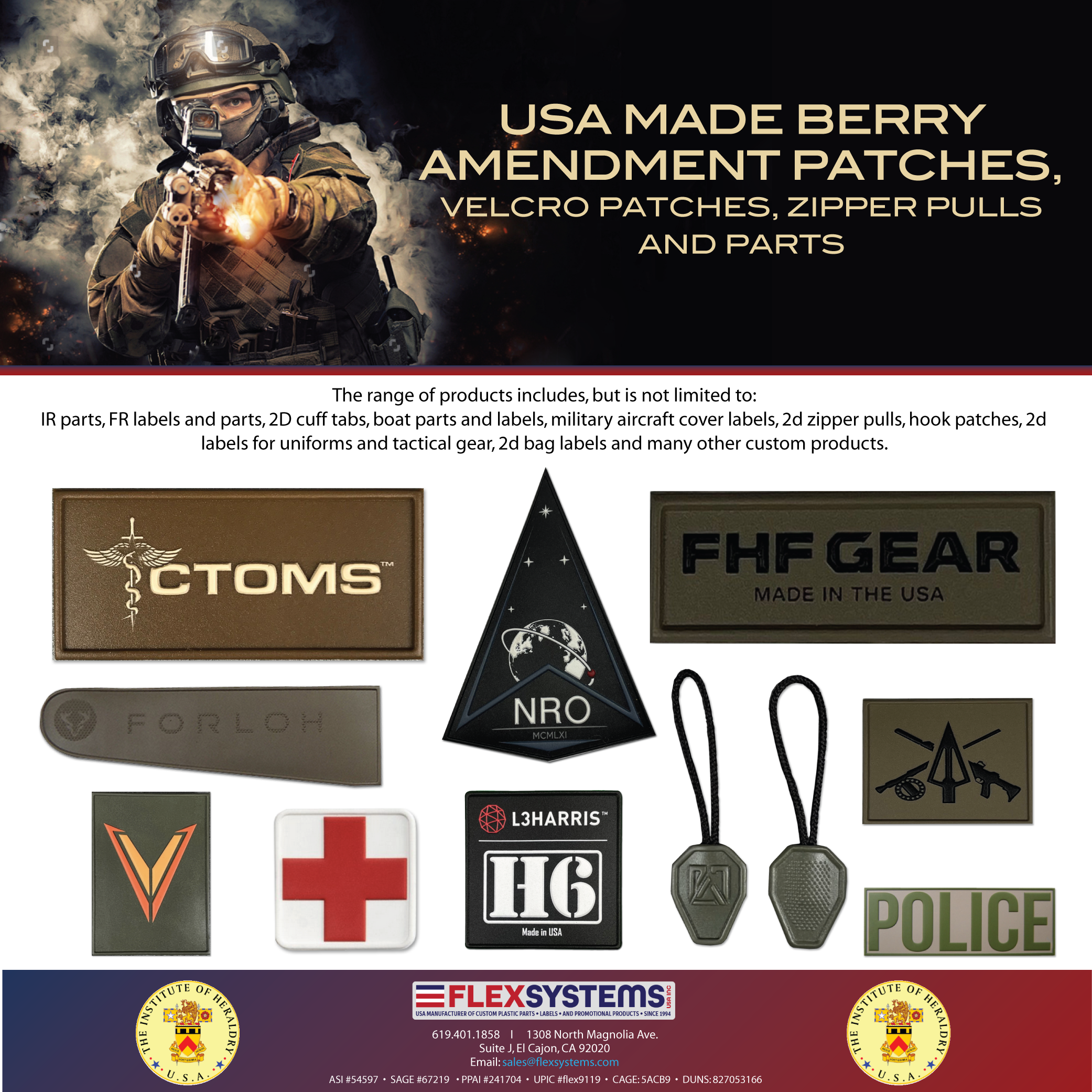

In addition to manufacturing the PVC morale patches we guve away at tradeshows, our friends at Flex Systems make other Berry Compliant items like tags and pulls.

flexsystems.com/custom-manufacturing/berry-amendment-parts-and-patches

In addition to manufacturing the PVC morale patches we guve away at tradeshows, our friends at Flex Systems make other Berry Compliant items like tags and pulls.

flexsystems.com/custom-manufacturing/berry-amendment-parts-and-patches

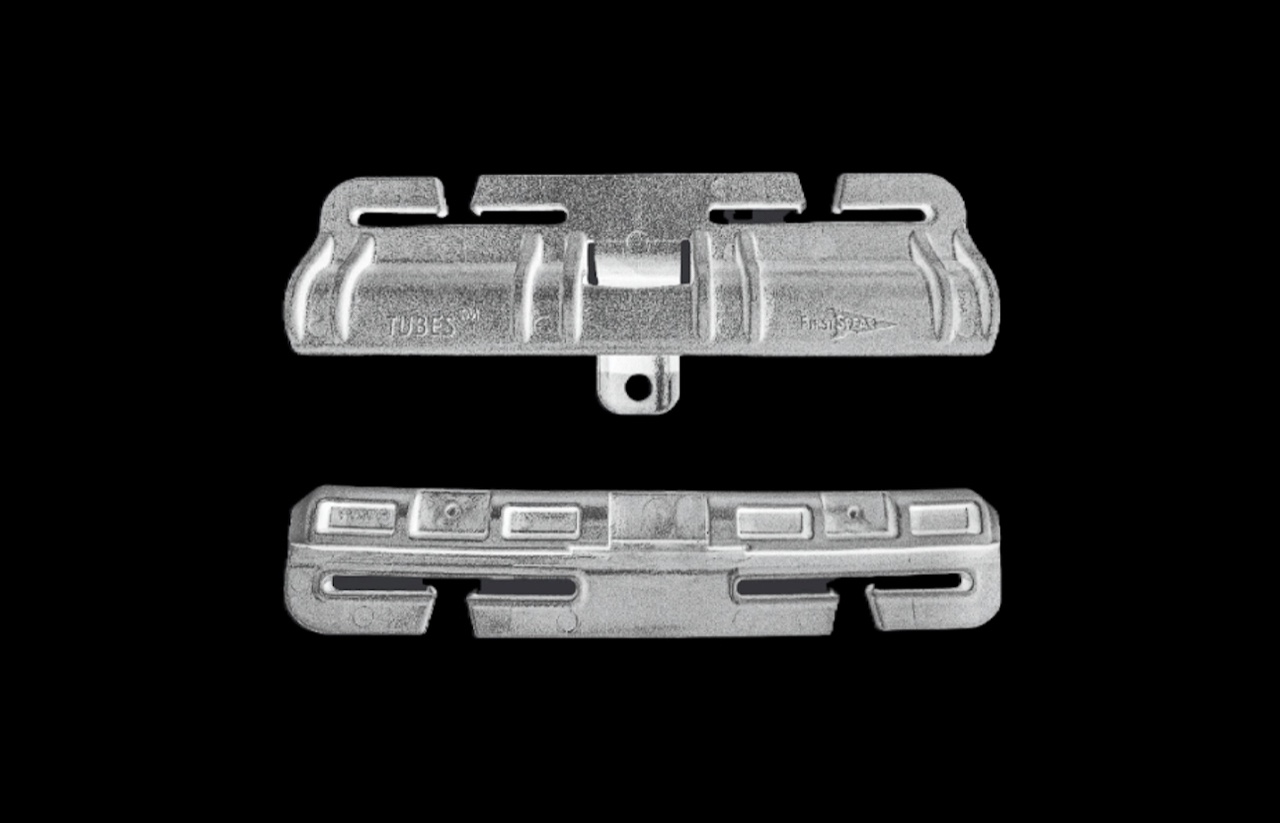

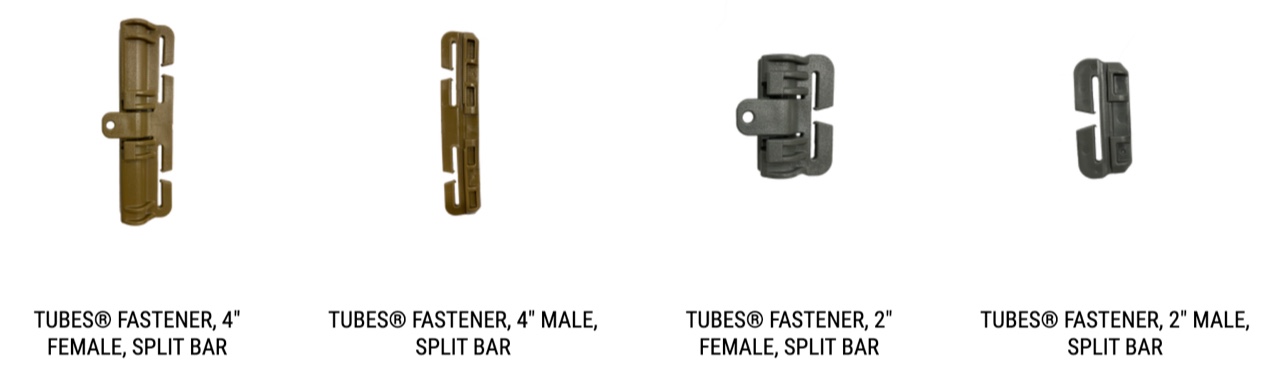

FirstSpear is pleased to announce the official release of Split Bar Tubes® Fasteners for purchase on the web.

Male and female Split Bar Tubes® Fasteners are offered in 4 inch and 2 inch sizes as well as four different colors: black, coyote, foliage green and tan.

Tubes® Quick Release technology allows end users to don and doff in seconds. Single handed operation with a two-motion quick release allows you to engage the lift gate with 3 to 4 pounds of force and slide in either direction to release the buckle. Ditch your cable, faster re-assembly and repeatable fit every time. Tubes® Fasteners eliminate the need for additional layers of fabric and Velcro and effectively reduce weight. Tubes® Fasteners meet all U.S. military specifications for infrared signature reduction between 600 to 800 nanometers.

FirstSpear is in the business of providing innovative solutions to long unanswered challenges. Our Tubes® technology reaffirms that position. Quick to close and even quicker to doff, Tubes® fasteners are manufactured from lightweight high-performance polymers that exceed the strength of other molded fasteners currently used on operational equipment. Molded in signature suppressive colors and with a variety of choices for activation, this closure system can be rapidly deployed and completely reassembled in SECONDS. Tubes® technology will improve performance, enhance mission functionality, and reduce weight.

Visit FirstSpear to find all the gear and apparel for America’s Warfighter.

The Launch Everyone Has Asked For.

FirstSpear will soon launch Tubes® Rapid-Release Technology for purchase on the web. Stay tuned for more deets.

FirstSpear is in the business of providing innovative solutions to long unanswered challenges. Our Tubes® technology reaffirms that position. Quick to close and even quicker to doff, Tubes® fasteners are manufactured from lightweight high-performance polymers that exceed the strength of other molded fasteners currently used on operational equipment. Molded in signature suppressive colors and with a variety of choices for activation, this closure system can be rapidly deployed and completely reassembled in SECONDS. Tubes® technology will improve performance, enhance mission functionality, and reduce weight.

Check out FirstSpear to find all of our apparel and gear for America’s Warfighter.

PORTSMOUTH, RI – May 23, 2022 – Ocean State Innovations (OSI), a leading textile provider, announced the appointment of Peter Raneri as Global Sales Manager. Mr. Raneri joins OSI with over thirty years of textile experience. Most recently he held the position of VP Sales & Business Development at HLC Industries. In his new role for OSI, Mr. Raneri will handle domestic and global business opportunities in tactical, industrial and specialty market segments. Raneri has a strong partnership with the INVISTA™ CORDURA® team which will be an asset in growing both the OSI and the CORDURA® brands.

“Ocean State Innovations continues to evolve and grow. We made the commitment to textile assets with the purchase of ColorWorks, one of America’s largest dyers and finishers, and the purchase of Cutting Edge TexStyles, a premier bias and straight cutter of textiles. Now we are investing in people. Peter brings a global presence to our sales force, specializing in the CORDURA® brand, but also brings a wealth of knowledge and relationships in the textile industry that will help us grow to the next level,” said Bryan Boulis, President of Ocean State Innovations.

For more information, please visit www.osinnovate.com

The Fuel Handler Coverall has been replaced with a new two-piece design made from GORE-TEX PYRAD Technology and procurement is well under way.

Offered in Coyote, it is being used by both Army and Marine Fuel Handlers and intended to be worn over other garments. In addition to it’s FREE properties, the suit also provides weather as well as contaminant protection. Thanks to the GORE-TEX membrane, it’s also breathable, water and wind proof, and is quick drying.

Spartanburg, S.C. — Today, diversified global manufacturer Milliken & Company published its fourth annual Sustainability Report, a key reporting component in the company’s progress toward its 2025 Sustainability Goals. In 2019, Milliken laid out 12 sustainability goals, focused on its people, its products and the planet, as a roadmap to achieving a healthier tomorrow. Guided by the United Nations Sustainable Development Goals, these 12 goals signal the company’s commitment to sustainability in all forms.

In 2021, Milliken eliminated coal as a primary fuel after investing $25 million into cogeneration, which combines steam and power generation. Notably, Milliken also increased the diversity of its U.S. management team by 8% and announced that its entire flooring portfolio is now carbon neutral.

“Our shared purpose and our material science expertise make us uniquely Milliken,” shares Halsey Cook, president and CEO of Milliken & Company. “We embrace not only our ability to make a positive impact on the world around us but also our responsibility to build a healthier future for this generation and generations to come.”

Completed in line with Global Reporting Initiative (GRI) Standards: Core, Milliken’s fourth report details the holistic sustainability progress made in 2021. These efforts include:

· Recording zero lost time safety incidents from COVID-19;

· Logging 27,000 volunteer hours—the greatest number in company history;

· Partnering with groups including Accelerating Circularity, Polypropylene Coalition, PureCycle Technologies and the Alliance to End Plastic Waste to lend our expertise in solving product end-of-life challenges;

· Upgrading lighting to LED lights at 13 manufacturing facilities, reducing GHG emissions by 3,000 metric tons and marking the halfway point in the goal to convert all manufacturing facility lighting to LED by the end of 2023; and

· Increasing renewable energy use to 97,608 MWh/year, over 97% of the 2025 goal of 100,000 MWh/year.

“The cover of this year’s report is an image from the documentary, Everest, which details the dramatic true story of a team of four climbers who ascended the mountain,” says Kasel Knight, senior vice president and general counsel. “Milliken and Polartec are sponsoring the 25th anniversary re-release of this film. For us, this story of teamwork, hope and perseverance was a natural fit for our 2021 report. Our goals are lofty, but working together, we know that we can achieve a brighter, healthier tomorrow.”

To view the complete report, visit Milliken’s Sustainability Hub here.

During a couple of recent trade shows, I caught up with the INVISTA team responsible for the CORDURA line of fabrics and realized that they had introduced quite a few new fabrics I wasn’t aware of. I asked them for some more information to share with you.

Here is a sampling of the lineup:

CORDURA® NYCO Knit – Soft comfort performance with staying power

Engineered with military-grade INVISTA T420 nylon 6,6 staple fiber blended with cotton for a natural look and feel, CORDURA® NYCO Knit combines soft comfort performance with long-lasting durability.

CORDURA® Classic Fabric – The original CORDURA® fabric made with a cotton duck appearance optimized for abrasion resistance

Designed for living and built to last, the original durable CORDURA® fabric has proven performance in many of the world’s toughest environments. Made with high tenacity air jet textured nylon 6,6 filament yarns in a range of sizes – 370, 560, 770, and 1100 dtex.

CORDURA® TrueLock™ Fabric – Eco-friendly fabrics with locked-in color

Engineered with high tenacity nylon 6,6 multi-filament fiber that is solution dyed, locking the color in at the molten polymer extrusion level, CORDURA® TrueLock™ Fabric has excellent color-fastness, UV-fade and abrasion resistance, lot-lot-color consistency, extended UV strength stability, and long-lasting color vibrancy. The process used to make CORDURA® TrueLock™ Fabric also uses less water, energy, and CO2 to help leave a lighter footprint along the path to sustainability. CORDURA® Truelock™ Fabric is available in classic US Military and other tactical colors with built-in IR signature management for improved concealment (Coyote-498, Desert Sand-503, Tan-499, Camo Green-483, Ranger Green, Black, and Wolf Gray). End-uses include bags, load carriage, and reinforcements as well as use in eco-friendly fabrics, webbings, and trims.

CORDURA® re/cor™ Fabric RN66 – ‘Expect More, Waste Less’

The new recycled nylon 6,6 (RN66) collection is ‘durable, responsible and innovated to last.’ In terms of quantifiable benefits versus Virgin Nylon 6,6, the production of CORDURA® re/cor™ Fabric RN66 decreases greenhouse gas emissions by 83%, consumes 82% less energy, and uses 57% less water. CORDURA® re/cor™ Fabric RN66 is made from 100 percent pre-consumer fiber material that is GRS (Global Recycled Standard) certified and can be produced in a full range of mil-spec colors.

CORDURA® Combat Wool™ – Comfort and aesthetics of wool with the performance of nylon

CORDURA® Combat Wool™ fabrics offer engineered endurance performance. Woven using INVISTA nylon 6,6 staple fiber that is intimately blended with merino wool for an authentic classic wool look and feel with enhanced comfort and up to 10x higher abrasion resistance***.

CORDURA® Naturalle™ Fabric – Technical performance with the look and feel of cotton

CORDURA® Naturalle™ Fabric is engineered with full-dull luster nylon 6,6 filament yarns and offer long-lasting, ruggedly stylish solutions for endurance apparel.

CORDURA AFT® Fabric – High-performance, breathable mesh fabric

Highly breathable knit constructions engineered for enhanced abrasion and snagging resistance, the CORDURA® AFT Fabric tactical focused fabric range includes high tenacity nylon 6,6 mesh materials that can be foam or felt laminated for outer shell footwear and breathable apparel applications.

For more information, visit www.CORDURA.com.