The launch of CORDURA® Wolf Gray TrueLockTM fiber is a major milestone for INVISTA’s Camden, S.C. facility, expanded with new equipment in 2017 to increase U.S. capacity of high-tenacity, nylon 6,6 specialty fibers for CORDURA® fabrics.

WICHITA, KS – September 10, 2018 – INVISTA’s CORDURA® brand announces its latest innovation in solution-dyed nylon (SDN) 6,6 fiber technology with mill partner MMI Textiles, a premier supplier and one-stop shop supplying fabric, webbing and elastics in the textile marketplace for more than 21 years. MMI Textiles is the exclusive North American provider of fabrics and webbing made with the new Wolf Gray CORDURA® TrueLockTM fiber, now through December 2018.

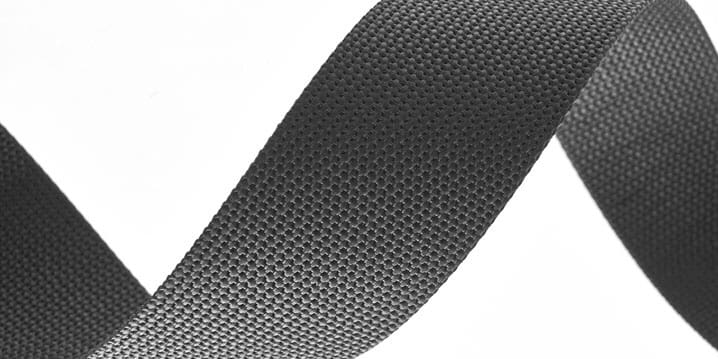

CORDURA® TrueLockTM fiber is created from INVISTA nylon 6,6 multi-filament fiber that is solution dyed, locking the color in at the molten polymer extrusion level to create deep, durable color throughout the entire fiber structure. Color consistency is crucial when pairing fabric with other materials such as webbing and elastic to create uniform garments and gear.

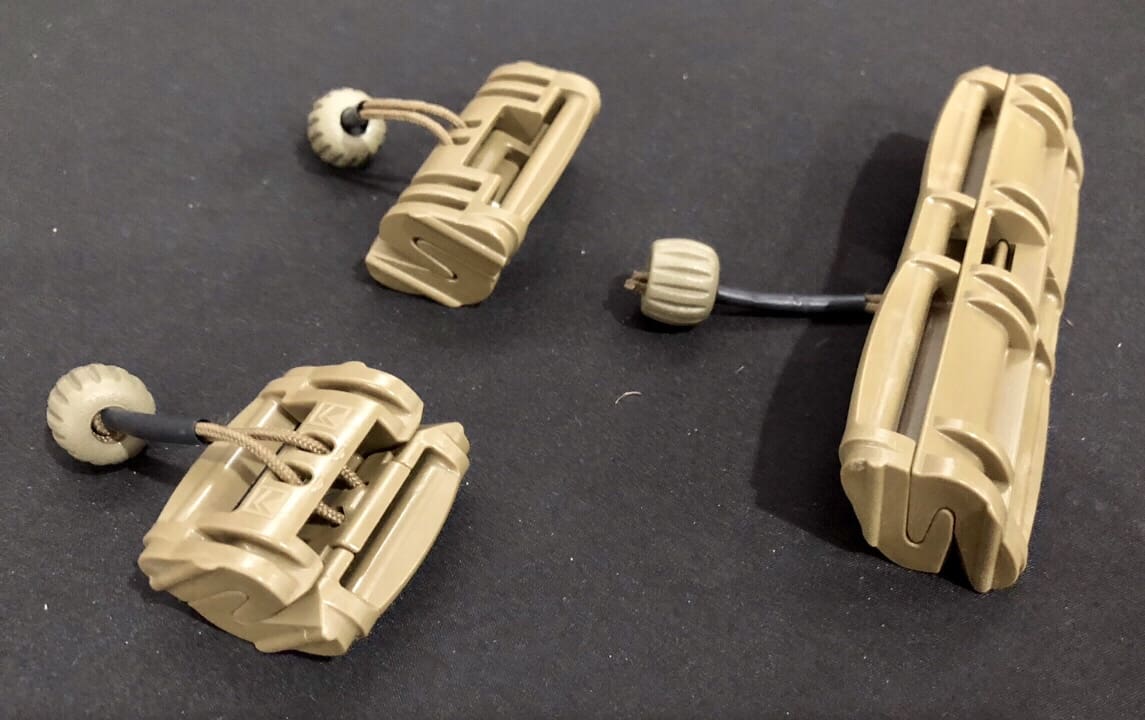

“Gray is one of the most commonly used colors in military/tactical applications, but was previously one of the most difficult to match, with several varying proprietary versions of ‘Wolf Gray’ on the market,” said Nick Rivera, director of operations at MMI Textiles. “One of our customers – TyrTactical – was having challenges matching webbings and fabric and came to us for a solution. We then turned to CORDURA® brand.”

“After examining six different shades of gray together, we worked hand-in-hand to create our latest innovative CORDURA® TrueLockTM fiber offering,” said Allen Mortimer, North American regional manager and product manager at CORDURA® brand. “The Wolf Gray shade of CORDURA® TruelockTM fiber offers color that is uniform across the components of gear and apparel, and durable enough to stay true after exposure to the elements and intense military missions.”

The color achieved with CORDURA® TrueLockTM fiber has inherent Near-Infrared (NIR) capabilities, is abrasion and UV-fade resistant and does not bleed or crock. With color-fastness locked in at the fiber level, excellent shade consistency lot-to-lot and across multiple textile components (such as fabric and webbing), UV strength stability, and long-lasting vibrancy are made possible.

The process of color encapsulation used in CORDURA® TrueLockTM fiber also offers several environmental benefits such as reduced water and energy consumption*, and reduced dye and chemical usage in textile processing.

The announcement is a major milestone for INVISTA’s Camden, S.C. facility, which expanded last year to increase U.S. capacity of high-tenacity, specialty fibers for CORDURA® fabrics. The Camden investment has accelerated progress in the development of new SDN capabilities – which complement the facility’s existing high tenacity nylon 6,6 filament fiber manufacturing processes.

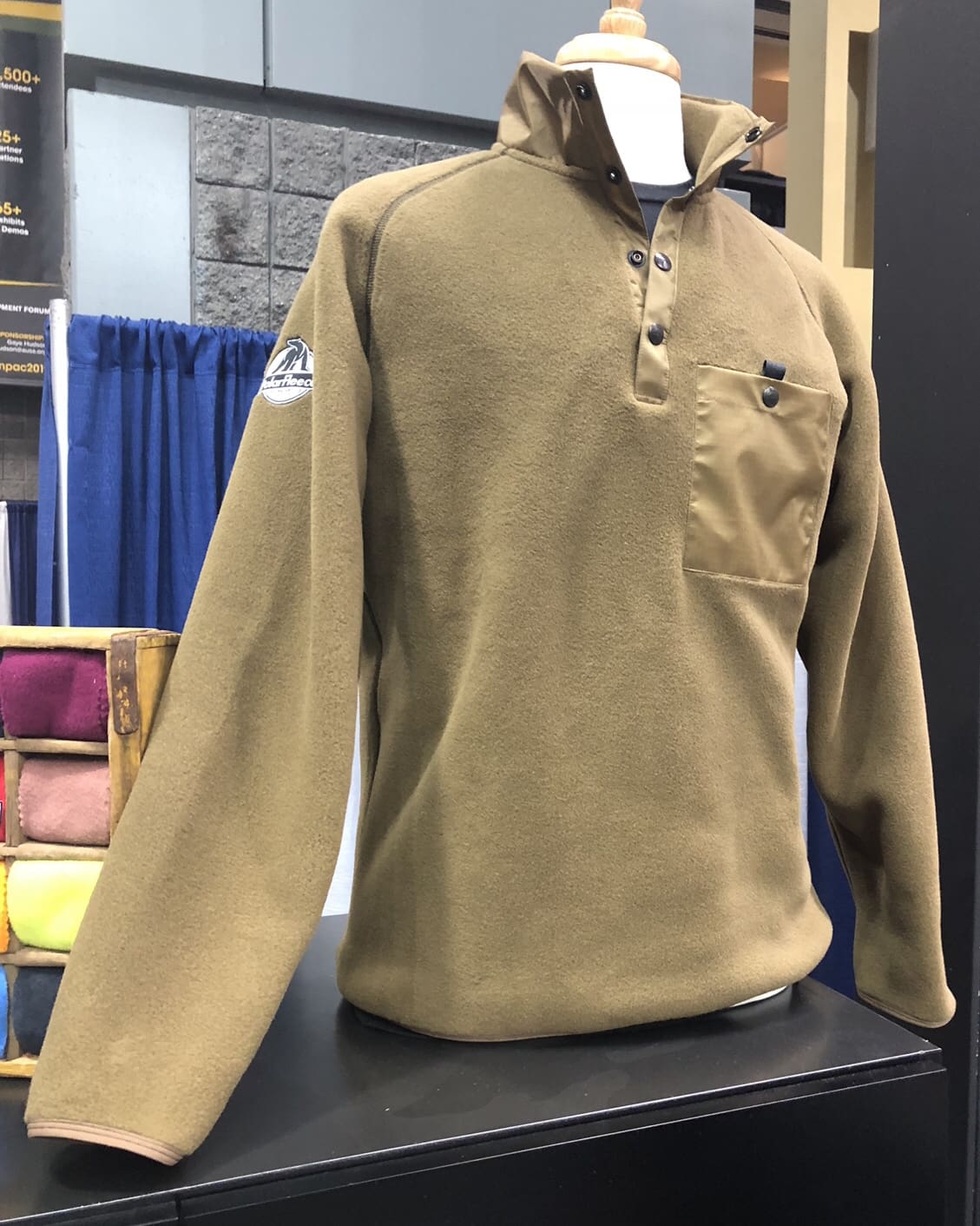

In addition to Wolf Gray, solution-dyed CORDURA® TrueLockTM fiber is available in Desert Sand, Tan, Coyote, Ranger Green, Camo Green and Black. Plans currently being put into action at Camden include expansion of the CORDURA® TrueLockTM filament product line to introduce additional standard colors and deniers, as well as the flexibility to work to smaller minimum order quantities and custom colorways.

“Throughout our 50-year journey, we’ve worked to establish a foundation built on durable and long-lasting fiber technologies, including our legacy of solution dyed, high-performance nylon 6,6 offerings,” said Cindy McNaull, global CORDURA® brand and marketing director. “The launch of our latest Wolf Gray CORDURA® TrueLockTM fiber is a testament to the strength of supply chain collaboration – a joint effort between an end-user, gear manufacturer, fabric supplier and fiber business.”

Tyr-Tactical gear in Wolf Gray is currently being put to the test by the Phoenix, AZ SWAT Team.

To learn more about the new Wolf Gray CORDURA® TrueLockTM fiber, visit www.cordura.com.

*2013 LCA study based on the average comparison of conventional level acid Piece Dyeing to SDN at 3 independent/3rd party dyeing and finishing mills.