Every two weeks SSD showcases a different MultiCam print fabric from Duro Textiles LLC. This week, we are covering Alpha. MultiCam is a single camouflage pattern designed to hide the wearer in varied environments, seasons, elevations, and light conditions. After a great deal of commercial success and adoption by elements of US Special Operations Forces, in 2010 MultiCam was selected for use by the US Army as its Operation Enduring Freedom Camouflage Pattern (OCP).

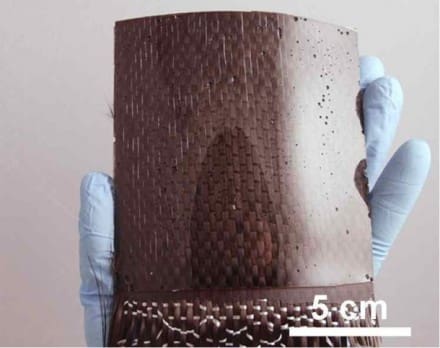

Alpha is heavier than Duro’s 40D 2-way stretch fabric and is ideal for more rugged use. It owes its stretch to a makeup of 91% Nylon 9% Spandex. Additionally, the face is NanoSphere® treated to maintain a highly water resistant finish.

Finished Width – 54 inches cuttable

Download a test report here.

Crye Precision has just released their new G3 All Weather Combat Pants. They incorporate all of the features of the G3 line of combat clothing but with the addition of Duro’s Alpha fabric. Alpha’s excellent abrasion resistance as well as wind and water resistance makes them perfect for inclement weather applications.

Features include 10 pockets as well as accommodations for Crye’s patented removable AirFlex Combat Knee Pads. It incorporates a zip fly with Velcro closure and a low-profile adjustable waist feature. Berry Compliant.

Visit www.cryeprecision.com for information on their new All Weather Combat Shirt and Pants.

Duro offers progressive pricing based on the number of yards ordered. For more information on this or any of the full line of MultiCam fabrics visit www.multicamfabric.com or email Galpen_Ben@DuroLink.com.