Murdock Webbing has been officially licensed by Crye Precision to offer jacquard woven Multicam webbing. Using specialized jacquard looms the camouflage pattern is integrated directly into the web creating a durable, quality product. It meets or surpasses all of the performance requirements for AA55301 and is offered in standard widths of .75″, 1″, 1.5″, and 2″. Additionally, custom widths and weights are available upon request.

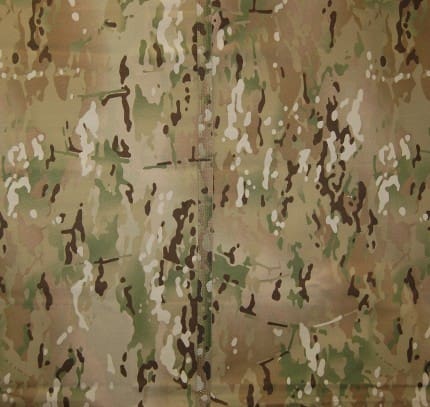

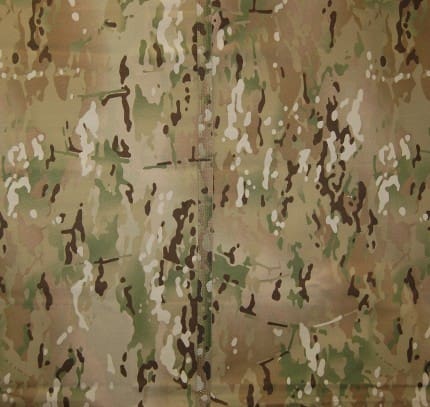

You can barely see the webbing overlayed on a sheet of MultiCam fabric. This is a good thing. The pattern is so well executed that it blends right in unlike the Government pattern webbing introduced earlier this year.

The double-sided jacqaurd woven MultiCam webbing meets all NIR requirements established by Natick, and has been approved by a government certified lab.

In addition to looking great, there is an added benefit to the jacquard woven construction. It has proven to be very abrasion resistant in repeated laboratory tests, maintaining the integrity of the MultiCam design even after 1000s of cycles on an abrasion machine. This means the pattern is going to last you the lifetime of the product.

Additionally, the weave can really hold a buckle or clip in place. Murdock Webbing feels that this could be the single most important function of webbing as it relates to a military pack or carrying system. We agree. There is nothing worse than webbing that needs constant adjustment due to slippage.

What’s more, Murdock Webbing is the exclusive narrow fabric company to offer Schoeller’s NanoSphere technology. NanoSphere repels water and dirt to create a self-cleaning finish and enhance durability. They also also offer a silicone application that they apply in-house. Either of these treatments will protect the webbing and prevent water absorption to keep weight down when conditions get rough.

Murdock Webbing has been an approved supplier to the military since the early 1960s and has been a force in industry since 1936. Their mill is ANSI/ASQC ISO9001 certified and manufactures products that meet the highest standards of quality and reliability.

So, to sum this article up. Looks good? Check. Abrasion Resistant? Check. Grippy for Buckles? Check. Added Bonus – Inexpensive.

Murdock’s MultiCam webbing is woven right here in the United States and is Berry Amendment Compliant. Please contact Ray Clarke, VP of Sales, at 1 (800) 375 2052 x3014 or ray.clarke@murdockweb.com for free prototyping quantities as well as a price quote.

murdockwebbing.com