MCAS FUTENMA, Okinawa, Japan. – For Staff Sgt. Michael P. Burnham and Sgt. Blaine E. Garcia, a trailer-sized workspace filled with sweltering heat and the constant whine of over a dozen machines running at full speed is simply the setting for just another day. This day, however, sees these leaders bringing 3D printing to the fight for 1st Marine Aircraft Wing, using their manufacturing skills against COVID-19.

For Burnham, who originally joined the Marine Corps as a machinist working with ground ordnance, and Garcia, who started his career working on jet engines, the process of 3D printing has become less of an unexpected turn in their service and more of a passion. Garcia alone has several 3D printers of his own, once used for hobbies and now put into the effort by III Marine Expeditionary Force to print the frames for thousands of masks and face shields. Posters surround the machines churning away, each one highlighting a success story for 3D printing in 1st MAW and an example of the sort of additive manufacturing both Marines have spent years perfecting.

Today, Burnham and Garcia have put their experience into the fight against the COVID-19 virus. In their workspace on Marine Corps Air Station Futenma, the two have turned their workspace, ordinarily used for 3D printing parts for aviation maintenance, into a PPE factory. The goal of the overall effort, Burnham explained, is to reduce the need for medical-grade masks and respirators by providing an alternative supply of frames for masks and face shields to Marines and Sailors assigned to III MEF and its supporting units, particularly those directly engaged in first-line medical care and screening.

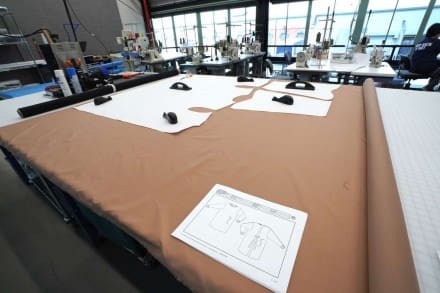

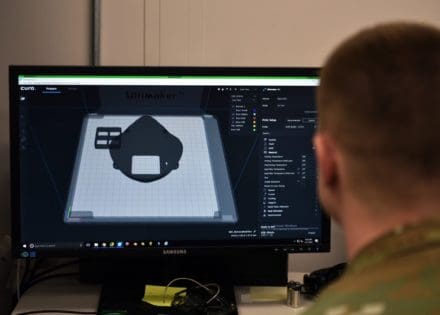

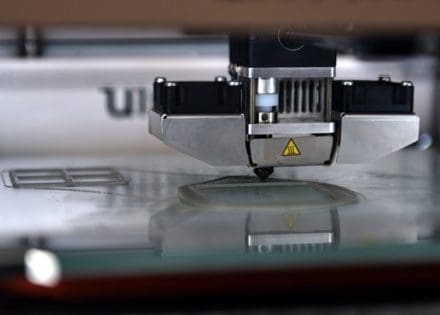

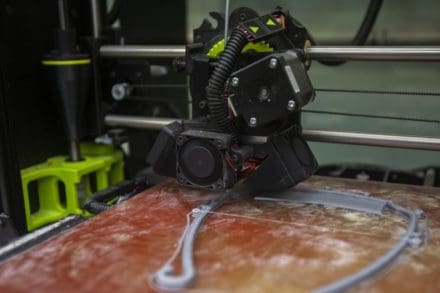

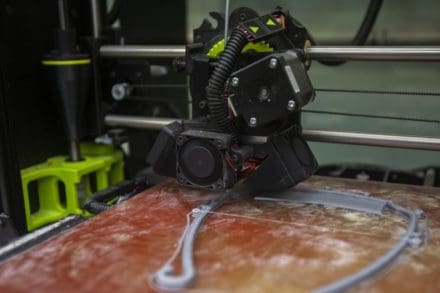

The plastic frames being printed, Burnham said, started as 3D models on a computer, designed with input from medical professionals and incorporating open-source ideas from others in the 3D printing community. Once the design is settled, a program “slices” the model into a series of programs for the 3D printer, which can then assemble a complete object from up to thousands of layers of two-dimensional patterns formed by cooling jets of molten plastic. The mask frames themselves can be created in a number of different plastic materials, and create a complete mask using elastic bands, cords, or other fasteners, along with an easily washable and readily available cloth cover. The plastic frame creates a seal around an individual’s mouth and nose, as demonstrated by Garcia, wearing the end result amidst the 3D printers at work.

The face shields are a more complicated product, also developed in concert with the U.S. Naval Hospital on Okinawa. Garcia has designed the face shield frames himself, with hospital public health officials providing quality assurance. “We start with a number of different prototypes,” he explained, demonstrating a number of designs that public health experts had directed alterations to. “We look at all the ideas, and each prototype goes through the QA process.”

The final design, he said, is deliberately simple but effective, an arc-shaped piece of plastic with a series of pegs and hooks along the outside edge. “We send the frames to the hospital,” Garcia explained, demonstrating the process of making a face shield with the frames using a plastic sheet protector. “They’ll clean them and use a plastic similar to the overhead transparencies they use in schools, with holes punched in them to fit over the knobs on the front.”

MALS-36 will be producing the face shield frames going forward, as part of III MEF’s overall effort, with other elements producing mask frames at a similar rate beyond the 1,000 already produced by MALS-36. This is nothing new, from Garcia’s considerable experience in the burgeoning field. “Any part that we print for an aircraft goes through reviews by engineers and experts,” Garcia said, “ensuring that [the parts] fit the tolerances needed and can stand up to the conditions. Once that’s done, it’s available to every Marine and Sailor who can print,” allowing the services to rapidly disseminate the designs that make the cut.

This division of labor, with different units producing parts and medical personnel taking the mass-produced frames for masks and face shields and overseeing the distribution, allows the MALS-36 team to focus on rapid and sustained production. 3D printing, Garcia noted, has a longer lead time initially than simply ordering parts that are in-stock, but once the initial design is finished, it allows for faster, cheaper, and more responsive delivery of parts – and it allows entirely new items to be created from scratch in remote conditions.

Around the clock, Burnham and Garcia oversee the process of production. Maintaining their distance from each other in both time and space, the two Marines work in shifts, with Garcia laboring to keep the morning’s mask and face shield production going and Burnham arriving in the afternoon, after Garcia has departed, to remove the finished products from their print beds and begin the process yet again. Despite the long hours, Burnham emphasized that 3D printing is not necessarily labor-intensive once production has begun. “We print them in stacks,” Burnham said, against the backdrop of another set of mask frames being printed. “Most of the time, if there’s a mistake, it’s in the first layer, so we can tell right away if we need to stop the machine and reposition.”

From there, the frames can be left alone, the workspace growing noticeably hot inside as a dozen nozzles spread heated plastic out in an exacting pattern. After 11 hours, the frames are ready to remove from the printer and separate into individual items – and at two to four stacks of ten mask frames each per machine, this adds up quickly, allowing any similarly-appointed workspace to create over 800 mask frames per day.

This output, according to Burnham, is a process that can be kept up 24/7. To accomplish it, the machine’s print head moves from side to side, while the print bed itself, the large plate upon which the object is printed, moves forward and back. Each layer of the object is painstakingly assembled by the minute, programmed motions of the print head, feeding a heated stream of molten plastic precisely into place. The smaller machines print more slowly, but use a smaller filament, allowing for finer detail to be captured.

The entryway to Garcia and Burnham’s workspace is decorated by evidence of this fine detail, with everything from rocket parts and ornate, twisting test pieces to minutely-detailed decorations arrayed on tables in 3D printed wood, metal, and plastic. Even the fixtures within the workspace are 3D printed, with the handles suspending first aid kits and most plastic parts of the 3D printers themselves bearing the fine striations that mark a 3D printed product.

“With 3D printing,” Garcia said, “you’re really limited only by your imagination.”

Story by 1st Marine Aircraft Wing COMMSTRAT