In what many would consider an upset, GM Defense was selected to provide over 1,000 Infantry Squad Vehicles to the US Army. They beat out SAIC/Polaris and Osh-Kosh/Flyer both considered incumbents.

The Polaris DAGOR is in service with the 82nd Abn Div and the Flyer developed GMV 1.1 is in use with USSOCOM and the 173rd Abn Bde.

GM Defense LLC, Detroit, Michigan, was awarded a $214,297,869 firm-fixed-price contract for acquisition of the Infantry Squad Vehicle, installation kits, ancillary hardware and logistical support. Bids were solicited via the internet with three received. Work locations and funding will be determined with each order, with an estimated completion date of June 24, 2028. U.S. Army Contracting Command, Detroit Arsenal, Michigan, is the contracting activity (W56HZV-20-D-0066).

The GM ISV Is powered by a 186-horsepower, 2.8L diesel powerplant and six-speed automatic transmission, the nine man crew is protected by a Roll Over Protection System which serves as a roll bar, but can be stored for air transport.

Based on their successful Chevrolet Colorado midsize truck architecture and its ZR2 and ZR2 Bison variants, this GM truck could make the beginnings of an entire fleet of commercial off-road vehicles to handle the US military’s dat-to-day tasks in a similar fashion to the Commercial Utility Cargo Vehicle programs of the 70s-00s.

Below, is the US Army announcement.

Infantry Squad Vehicle to ‘motorize’ IBCTs

DETROIT ARSENAL, Mich. – The Army today announced it has selected GM Defense, LLC, Detroit, Mich., to produce the Infantry Squad Vehicle, or ISV, to motorize Infantry Brigade Combat Teams. Delivery of this modernized capability is slated to begin with the 1st Brigade, 82nd Airborne Division, as the designated First Unit Equipped next winter. The contract is valued at $214,297,869 and the Army intends to purchase 649 vehicles.

It is based on the Chevrolet Colorado ZR2 architecture, which will derive 90 percent of its parts from commercial-off-the-shelf components.

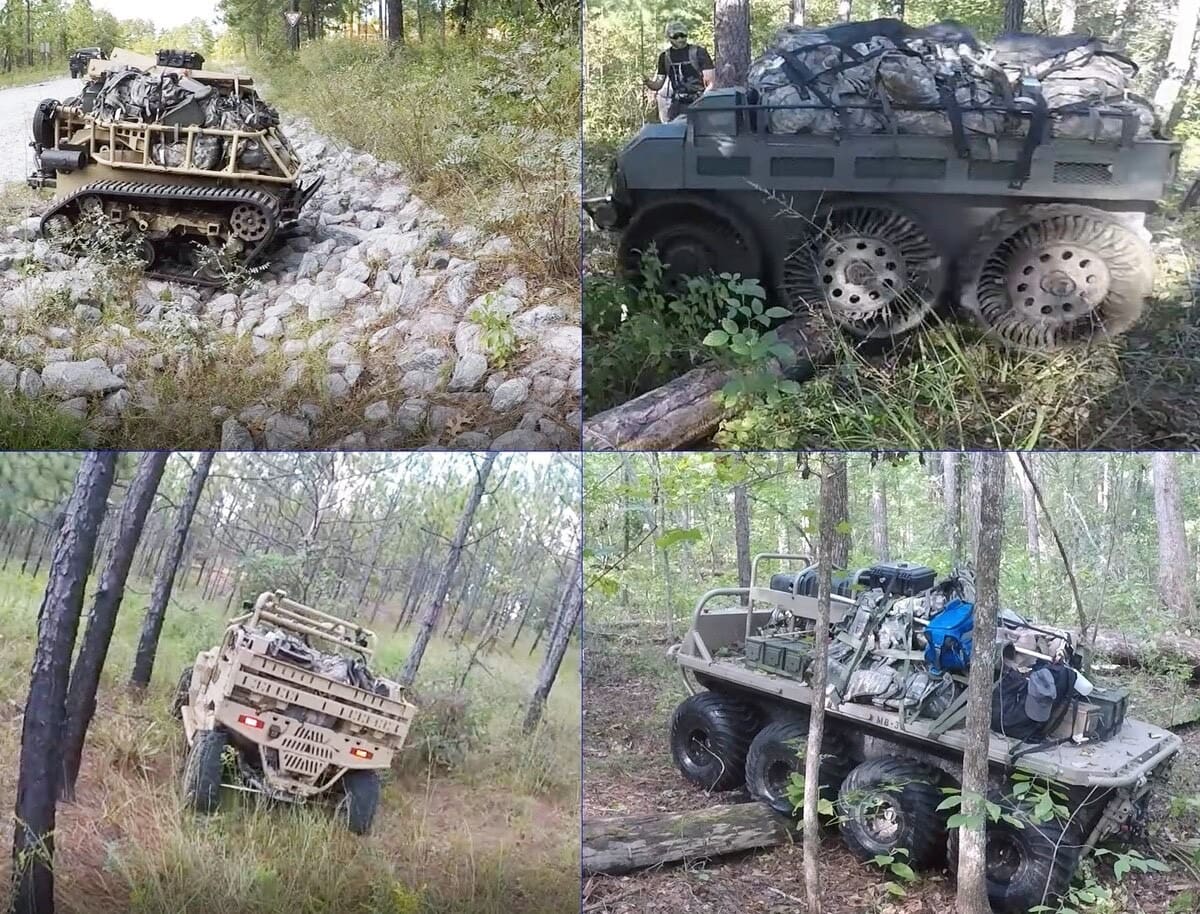

The ISV program provides IBCTs an additive lightweight vehicle to move Soldiers and their equipment quickly over complex and difficult cross-country terrain. ISVs will provide greater mobility to IBCTs, as they are designed to move across restrictive terrain, allowing Soldiers to close on objectives with less fatigue and greater readiness. The Army can deliver the vehicle to the field by airdrop or helicopter, which increases the flexibility of Soldiers on the move.

This is the second important production contract award for Army light tactical wheeled vehicle modernization programs of record in the last year. The Army announced in June 2019 the production contract of the Joint Light Tactical Vehicle. JLTV is modernizing the Army’s and U.S. Marine Corps’ light tactical wheeled vehicle fleets with a leap-ahead balance of payload, performance and protection.

“The Infantry Squad Vehicle meets the challenges we’ve faced to give our IBCT Soldiers greater mobility and increased survivability,” said Chris Stone, the Maneuver Capabilities Development and Integration Directorate’s deputy Army capability manager – Infantry Brigade Combat Team at Fort Benning, Ga. The CDID is the Army’s proponent for generating and validating the operational need for the Infantry Squad Vehicle.

“As the Army’s newest light tactical vehicle, ISV will allow IBCTs more flexibility and a greater advantage getting to the objective,” he added.

The ISV’s basic operational capabilities include:

Nine-man squad carrying capability

Payload of 3,200 lbs.

External sling load by a UH-60 Black Hawk helicopter

Internal load/external lift by CH-47 Chinook helicopter

Low-velocity air drop by fixed-wing C-130 or C-17 transport aircraft

Exceptional mobility over all terrains

The comprehensive team responsible for bringing the ISV program to production contract award involves not only Army acquisition professionals, but also relevant stakeholders representing the Army’s funding and testing communities, Army Futures Command, and Forces Command. Soldier evaluation via user-acceptance efforts has been a key element of the ISV program from the outset, and has helped compress the time it takes to field a modernized capability that meets infantry Soldiers’ needs.

“The Infantry Squad Vehicle program has focused on meeting the Army’s emphasis on enhancing Infantry Soldier mobility and survivability by rapidly fielding modernized capabilities. Our product management team for Ground Mobility Vehicles undertook a great challenge to develop a strategy using experimentation and technical demonstrations to streamline the ISV acquisition process,” said Timothy G. Goddette, the Army’s program executive officer for Combat Support and Combat Service Support, or PEO CS&CSS, headquartered here.

“Using an innovative acquisition approach through an Other Transaction Authority — a flexible, collaborative tool designed to speed acquisition and modernization — the ISV team awarded the production contract for this capability in 16 months. Using normal acquisition processes, it could have taken as many as 36 months,” Goddette explained.

The ISV acquisition strategy was structured to promote the highest level of competition possible, including affordability. Due to competition, the program office will realize a reduction from the original independent government cost estimate for the program. This provides best value to American taxpayers. What’s more, a senior Army officer who has commanded at all levels in an IBCT was tapped to serve as the ISV program’s Source Selection Authority.

According to Steve Herrick, the Army’s product lead for Ground Mobility Vehicles, PEO CS&CSS, the next steps in the ISV program include GM Defense delivering eight ISVs to Aberdeen Test Center in Maryland within four months. “Following delivery, our program office, along with Army testers, will execute an aggressive and tailored testing plan,” he said.

Herrick went on to explain the Army will conduct tailored production qualification testing to address the vehicles’ ability to meet the performance specifications in areas not previously tested. This will also build confidence in areas already tested, he said. The ISV will also undergo transportability certification, which includes low-velocity air drop and helicopter sling loading. Next summer and fall, the Army will hold an initial operational test and evaluation.

“The program office is marching toward delivering ISVs to the first unit, the 1/82nd at Fort Bragg, approximately eight months after the contract award,” Herrick added. “We are excited about the commercial nature this product brings to the Soldier, and in the future, we could possibly see greater leaps in technology and concepts to include reconnaissance or electric vehicles.”

By Rae Higgins, Program Executive Office for Combat Support & Combat Service Support