Coming soon to a DA hit near you, Ground Mobility Vehicle System (ver 1.1) is SOCOM’s concept for a new truck to replace their HMMWV-based systems currently in service. Since the solicitation is expected to kick off in September, several companies have been showing their wares. However, one company has been flying under the radar yet delivering capability for years.

The Search & Rescue Tactical Vehicle (SRTV) produced by BC Customs (BCC) is in the tactical family of SXOR Mobility Vehicles. The SRTV is a platform based family of vehicle utilizing identical components with multiple body configurations. The result is a range of dimensions, crew compliments, and capabilities with no additional training or sustainment requirements.

The SRTV is constructed of MIL-STD aircraft tubing, minimizing weight, maximizing strength, and providing a skeletal base for multiple types of Commercial off the Shelf (COTS) ballistic and blast armoring. BCC has utilized readily available components from the Rock/Desert racing industry with special attention paid to redundant systems required for military operations.

The SRTV has produced documented speeds of over 100 mph; vertical grades over 70 degrees, side-hill angles of over 60 degrees including a vertical step of 3 plus feet. Additionally, the SRTV can exceed double its curb weight in payload. BCC has been at this for some time and has integrated all standard military vehicle requirements such as run flats, open electronics (including Tactronics’ C4I system) as well as redundancy in all major operating systems.

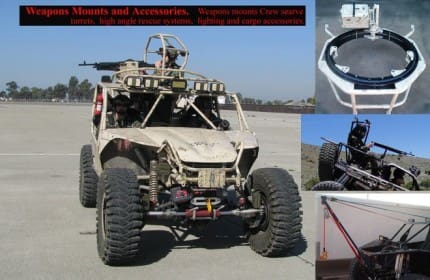

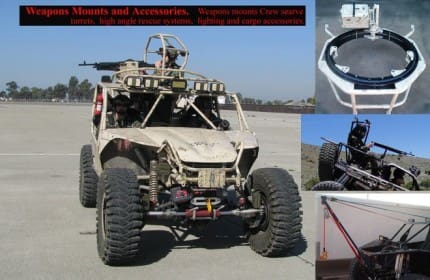

There are weapons mount options: Fore and aft crew serve weapon mounts, 360 degree turret with roll protection, and standard swing arm mounts. BCC has also been working with Garwood Ind to integrate their M134 Minigun, FN to integrate their light Weapon Stations, and MSG for multiple weapon stations.

Nicknamed the “Warthog” by users, the SRTV-5 has an internal crew of three with options for up to two additional crew and two internal (roll protected) patients. The SRTV-5 is internally loadable in the CH-53E and CH-47 with rapid ground mobility within one minute.

The SRTV-22 (Osprey) variant has an internal crew of three with options for two additional crew or two (roll protected) patients, but loses either one crew member or patient as required. The variant is designed to quickly load and unload from the V-22 with no major adjustments other than collapsing the roll protection. With practice, this can take the crew only a few seconds. The body is built to meet all V-22 tolerances, including ramp over angle and footprint. Additionally, it is less than 900 lbs per wheel, making it ideal for use as an Internally Transportable Vehicle (ITV) and can be ordered with the V-22 trailer. The ramp angle and weight per wheel issues are two of the biggest issues facing vehicle designs intended for the V-22.

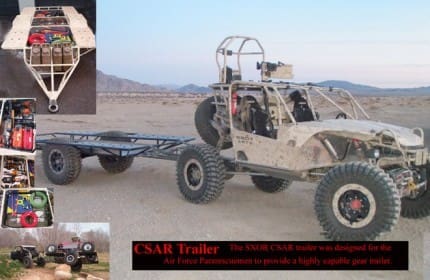

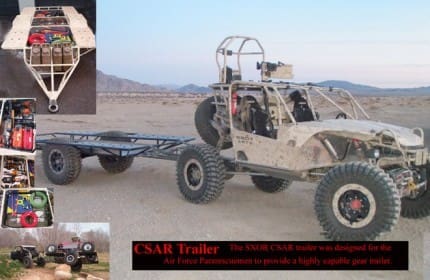

In addition to SOCOM interest in a new vehicle, the USAF’s Guardian Angel community recently released their third RFI in as many years looking for a specialized light rescue vehicle capable of internal and sling load transport as well as airdropability. Additionally, the RFI mentions a vehicle that can transport two PJs as well as two litter patients. BCC seems well positioned for this Guardian Angel Airdroppable Rescue Vehicle (GAARV) requirement. All SRTV variants can carry two external patients (Stokes, Israeli, Talon, or pole litters) without roll protection. Additionally, BCC is working with the Air Guard for airdrop certification.

For example, the SRTV-3 was originally designed for USAF Guardian Angel Forces in 2004 and fielded in 2007. Additionally, the SRTV was included in the Air National Guard’s (ANG) FY09 Weapons Systems Modernization Requirements documents specifically for Guardian Angel use.

BCC is currently working with the ANG on Airdrop and multiple MDS (aircraft type) ITV certifications to field a number of SRTV-5 and SRTV-22 variants for ANG rescue forces while awaiting the Air Combat Command (ACC) GAARV Solicitation process. BCC has recently fielded an SRTV-5 variant to the US Border Patrol special operations group BORSTAR. In addition to having an established product, they constantly work to improve existing vehicles as well as to develop new capabilities.

www.bccdod.com