The political opening of the Rheinmetall Ukrainian Defense Industry LLC maintenance and repair centre in western Ukraine took place yesterday (10 June 2024). On this occasion, the Ukrainian Minister of Strategic Industries, Oleksandr Kamyshin, visited the site there: “We strive to develop our production capabilities together with our allies and believe that the Ukrainian defence industry is a part of the European defence industry, which strengthens the system of collective security of the European Union. Therefore, the opening of a joint service center with Rheinmetall is not only a step towards the Victory of Ukraine, but also an important stage in the construction of the arsenal of the Free World.”

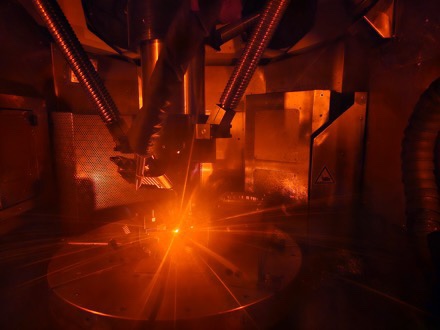

Marder infantry fighting vehicles are already being maintenanced and overhauled at the hub. In the future, Leopard 1 and Leopard 2 main battle tanks and other German-made systems will also be repaired at other locations in Ukraine.

Armin Papperger, CEO of Rheinmetall AG: “It is a matter close to our hearts to provide Ukraine with effective and reliable support. When it comes to supplying spare parts, our top priority is to maximise availability and ensure rapid replenishment. To achieve this, we utilise existing channels via original manufacturers, process material ourselves and with partners. We are also reactivating original supply chains and integrating local production in Ukraine.”

“The opening of the first joint service center with Rheinmetall in Ukraine is crucial for strengthening our defence capabilities. This facility will allow us to ensure quick repairs and maintenance of German equipment directly on Ukrainian soil, significantly enhancing the efficiency of our Armed Forces. We are grateful to our German partners for their trust and support, which enable us to confidently move towards victory and integrate into the European collective security system”, added Dmytro Klimenkov, Deputy Minister of Defence of Ukraine.

Rheinmetall is utilising existing local infrastructure, but has also brought special tools, spare parts and other equipment to the hub. Last year, Ukrainian specialists were trained at Rheinmetall sites in Germany in the repair of combat vehicles, including industrial mechanics and mechatronics engineers, for example. These personnel then returned to Ukraine and worked there on the maintenance and repair of the relevant systems.

The joint venture Rheinmetall Ukrainian Defense Industry LLC was founded in October 2023. The announcement was made at the German-Ukrainian Economic Forum in Berlin, in the presence of German Chancellor Olaf Scholz and Ukrainian Prime Minister Denys Schmyhal.