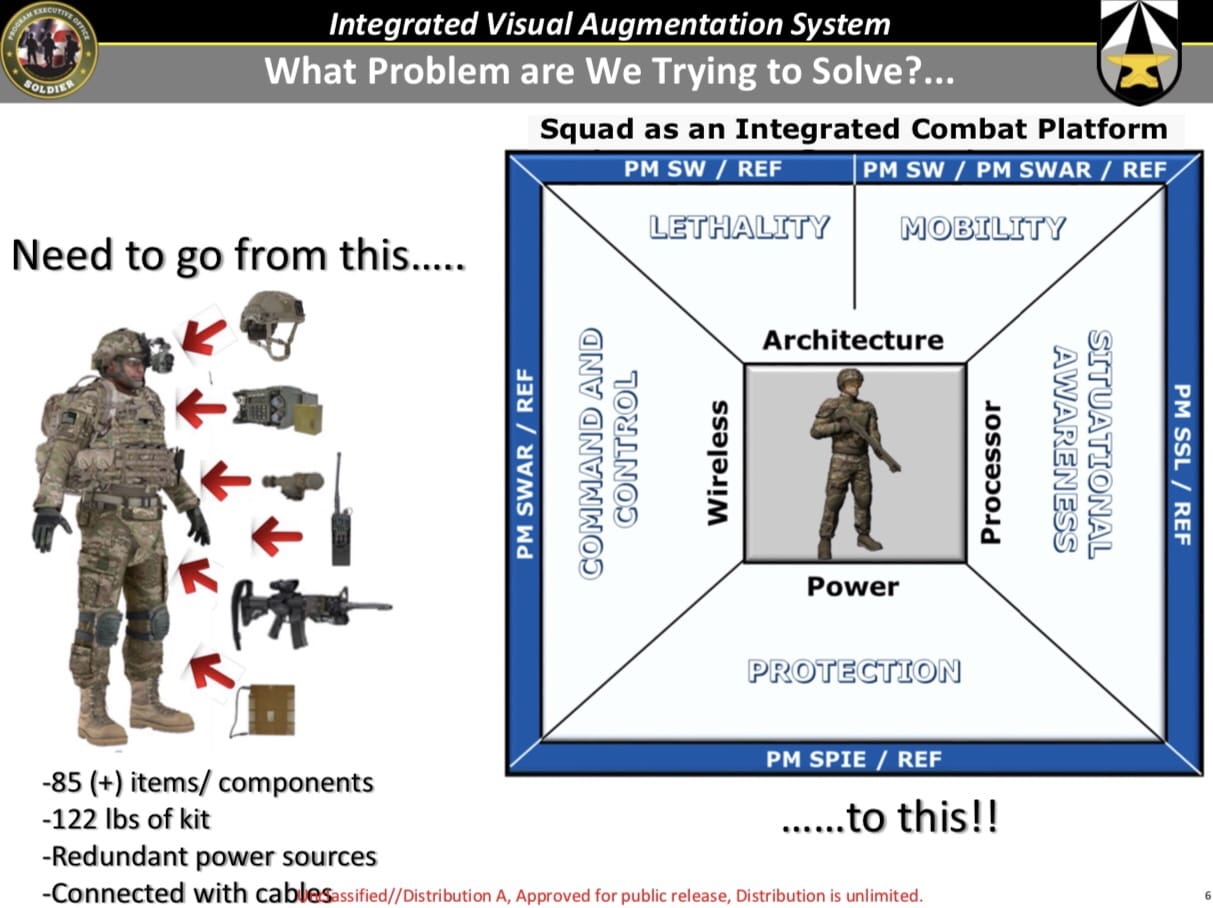

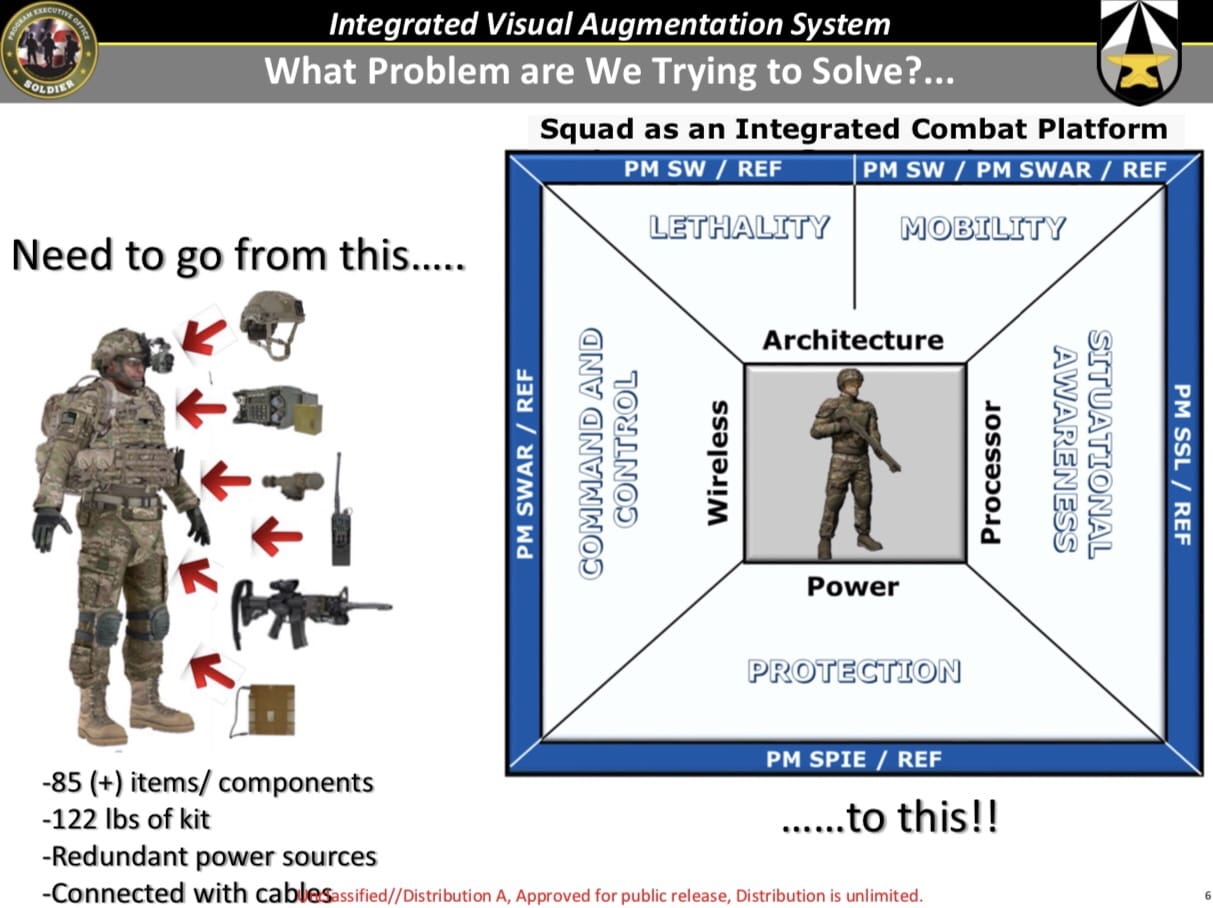

For too long, the Army has treated the Soldier like a Christmas tree, hanging pieces of equipment here and there. In total, it consists of 85 pieces of kit, weighing 122lbs with some of the burden owing to redundant power sources and connector cables. Adaptive Squad Architecture is going to change all of that.

To do this, the Army is preparing to undergo an 18-month effort to use a Modular Open Systems Approach (MOSA) to create system-level Interface Control Documents (ICD) for the Adaptive Squad Architecture.

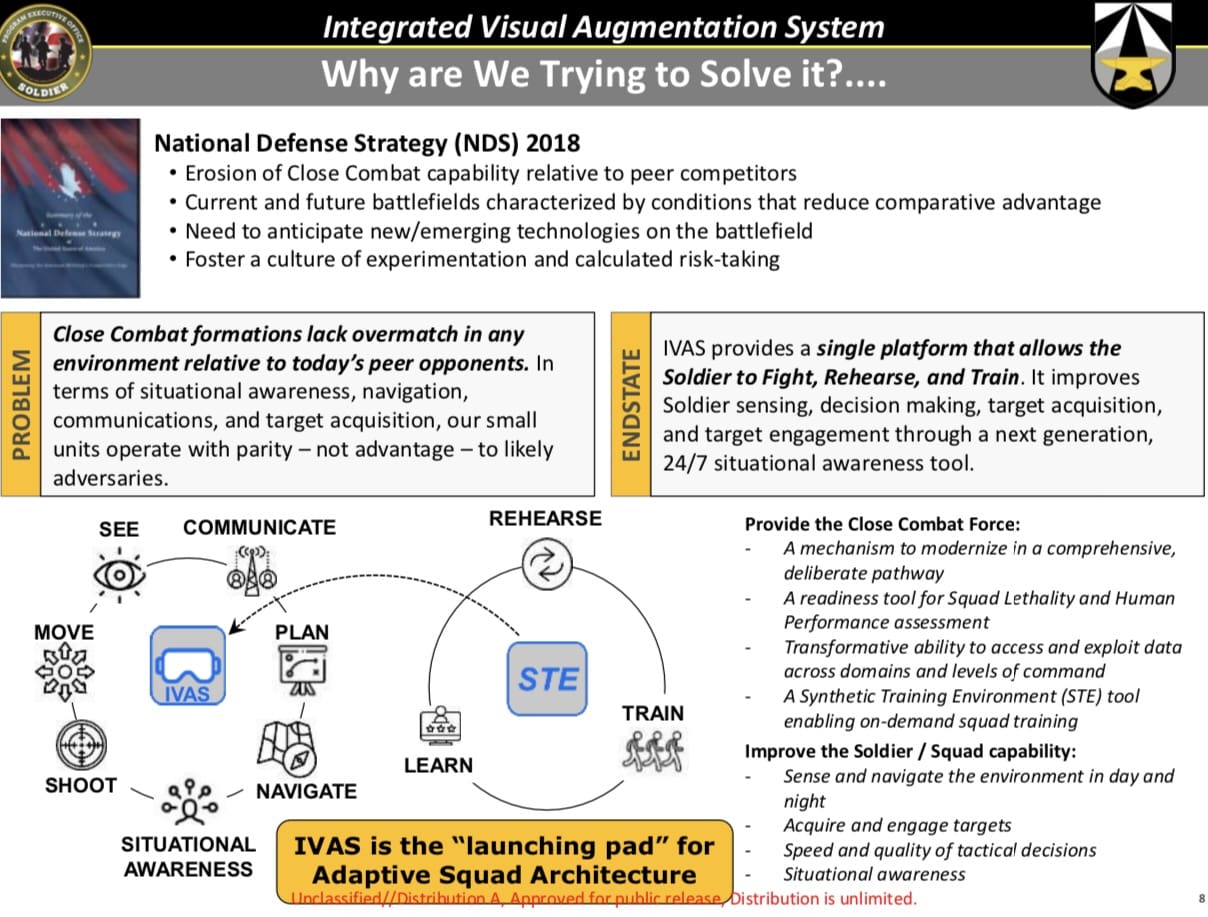

The Catalyst For Change

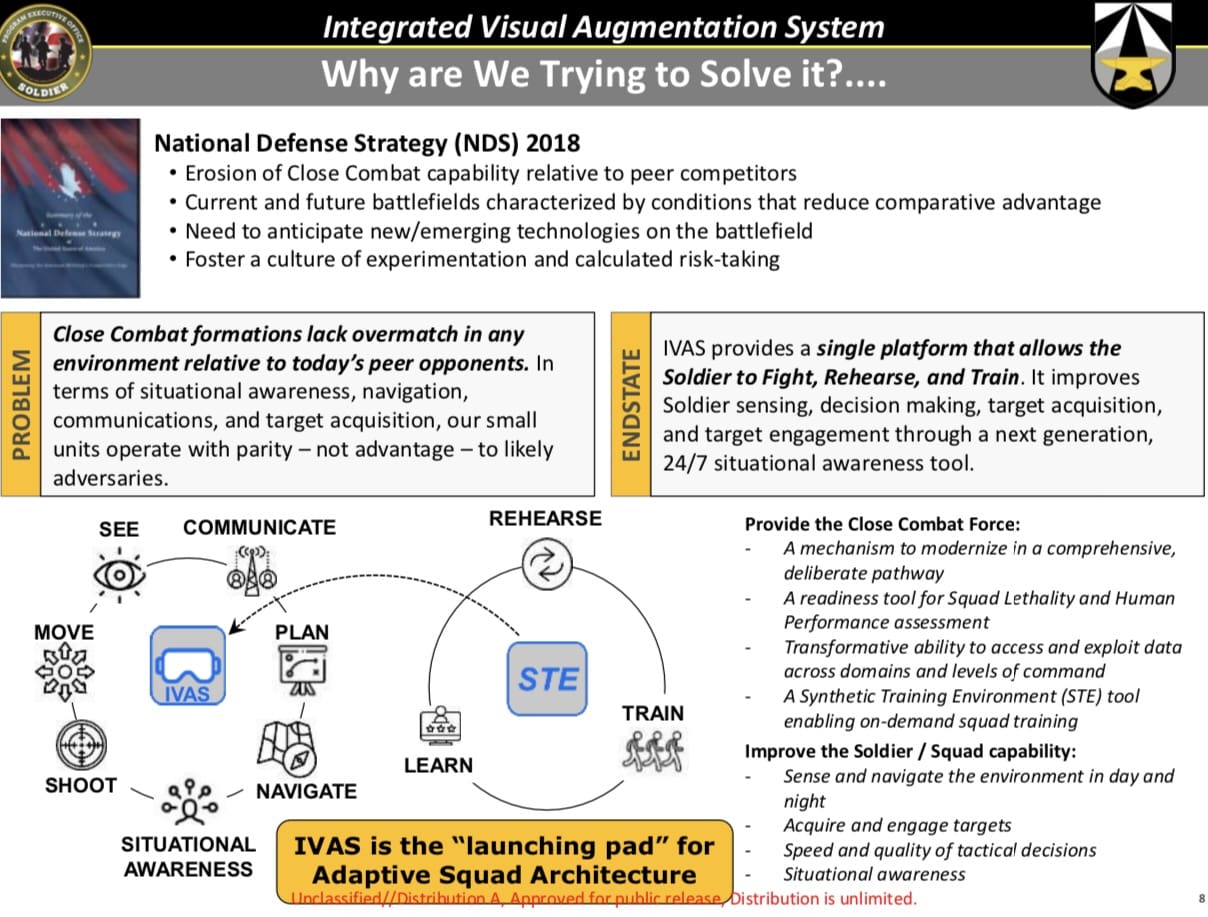

The catalyst for this transformation is the development of the Integrated Visual Augmentation System by Microsoft, a single system which allows the Soldier to Fight, Rehearse and Train. It integrates I2 with thermal IR cameras, overlaid with augmented reality information. Artificial environments and adversaries can be fed into the IVAS screen allowing for training and rehearsal. Machine learning and Artificial Intelligence will offer a more dynamic foe who learns from the Soldier’s actions, like a real enemy.

It is such a leap ahead, a whole architecture had to be developed along with it, including comms links and power. The Army concluded it was time to look at not just the Soldier, but the Squad as a whole.

The goal is to begin using the ASA by January 2021 as the foundation for achieving the Soldier as an Integrated Weapons Platform and the Squad as an Integrated Combat Platform making them a peer with other major weapon systems. To get there, they’re going to need standards for industry.

Interfaces

Key focus areas of the ASA will be establishing common standards and Interface Control Documents for power management; data management (on each Soldier, between Soldiers in the Squad, and between Squads); physical equipment interfaces; and size, space, and weight management at the Soldier and Squad level. ICDs will be living documents, adapting as technology improves.

Although, this article is primarily focused on the development of ICDs, ASA will also offer an Architecture Assessment Tool (AAT) and a Configuration Management (CM) Database which looks at the Soldier and Squad’s configuration and includes a visualization tool. The AAT allows the small unit leader to configure a Soldier and Squad, alerting to incompatible equipment choices and load weight concerns.

The MOSA approach is also intended to reduce the weight carried by Soldiers/Squads by having an architecture that facilitates combining multiple capabilities into a single hardware device and eliminating legacy hardware by developing software applications that can be used on existing peripherals.

Problem Solving

Adaptive Squad Architecture may be the most important undertaking PEO Soldier has ever performed. The very fact that PEO Soldier invited the media to attend their Industry Day is indicative of this fact. The last Industry Day we were invited to by PEO Soldier was the Camouflage Improvement Effort In 2009.

The name is exciting, but the work will be tedious, for government and industry alike. They plan to create system-level ICDs for a government-owned technical architecture for the Soldier as an Integrated Weapons Platform and the Squad as an Integrated Combat Platform. The goal is to make the Soldier and Squad into digital platforms. I look at ASA as akin to a Software Development Kit for the Soldier.

Primary stakeholders for the ASA are the acquisition community which directly supports the Soldier and Squad, namely the Science and Technology (S&T) partners, the combat developers, the materiel developers, and industry partners.

Although many of the Program Executive Offices across the Army will contribute to this effort, the program is under the watchful eye of PEO Soldier, BG Anthony Potts. Yesterday, he addressed a crowd consisting of government and industry professionals to layout the effort.

His biggest concern is that the ICD is meaningful to industry. He believes that the Army will initially get it wrong, but is prepared to work with industry to get it right. Communication is key. He also wants to energize better relationships with smaller, non-traditional entrepreneurs who have interesting, innovative solutions, without having to go through larger companies.

General Potts wants to focus on problem statements rather than solutions. This will allow industry to design and build, loosely coupled, highly cohesive, severable modules. Another important goal is to reduce proprietary designs. The Army will establish the interfaces, the ability to plug-in and plug-out (electrical, mechanical interfaces), but its up to industry to come up with the actual capabilities.

Earlier, I mentioned the Christmas tree analogy. General Potts used this example. The Soldier is burdened by a bunch of heavy ornaments like a Christmas tree. The call comes to reduce weight and make the Soldier more maneuverable, more lethal. That increased maneuverability means that a Soldier can draw and fire his weapon first. Potts comes to his conclusion, “He who draws first, generally wins.”

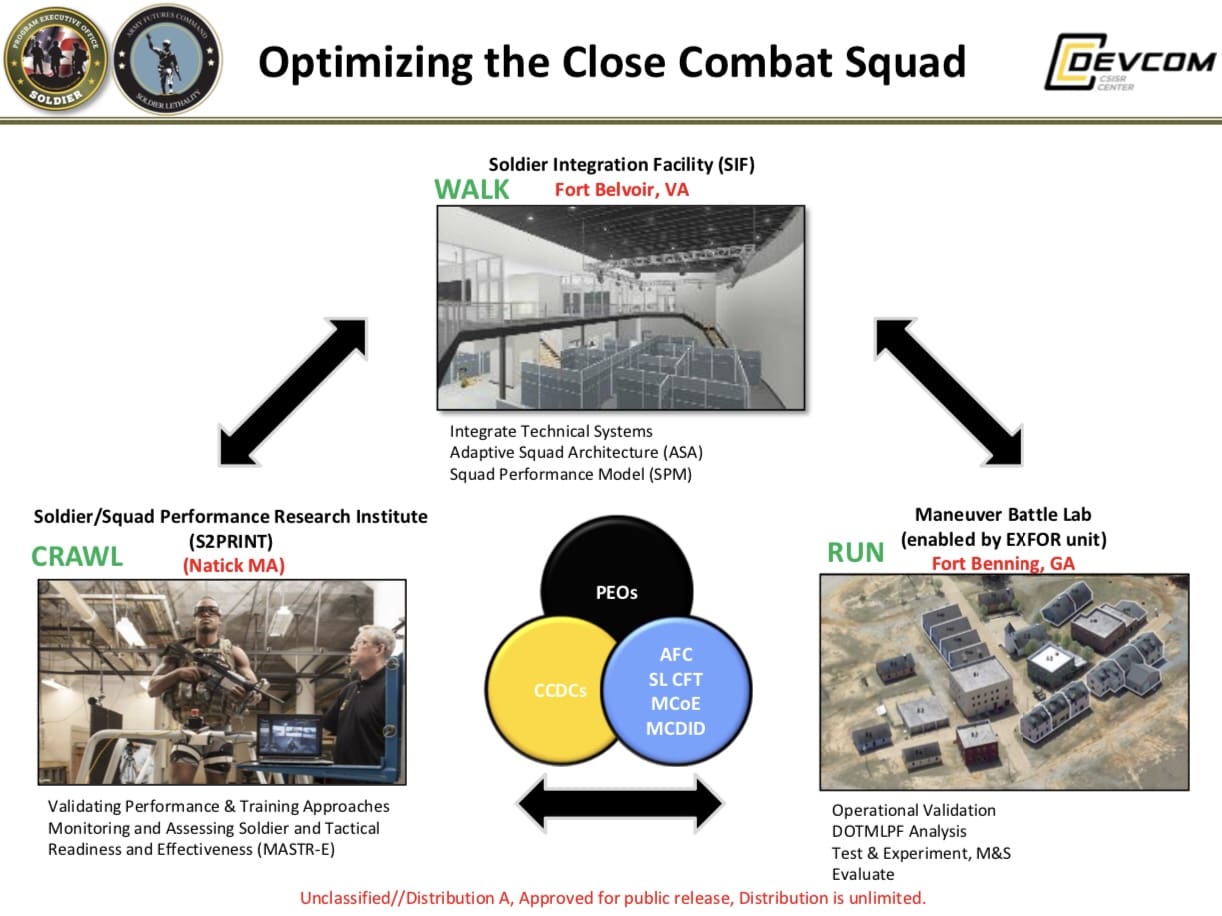

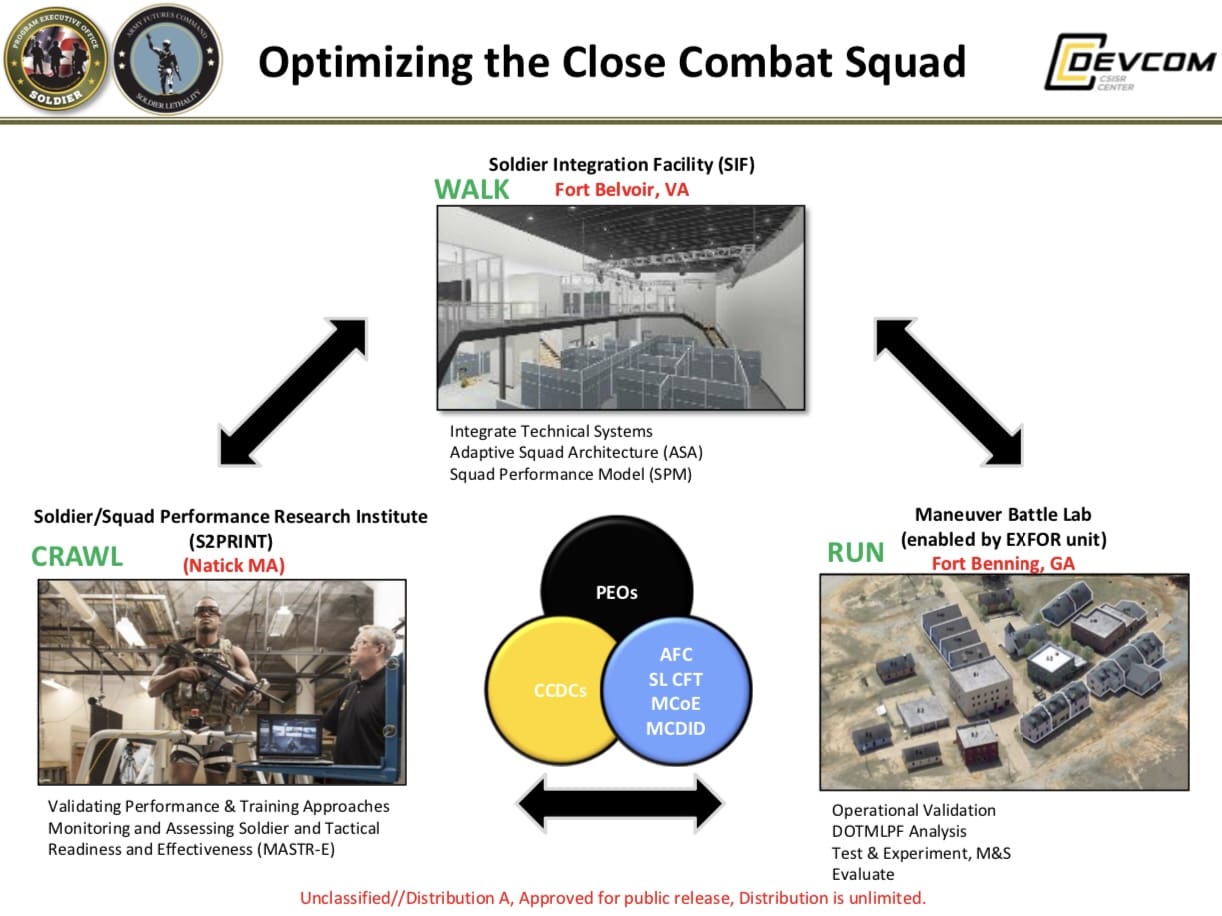

Soldier Integration Facility

One of the primary ways the Army is dealing with this new way of looking at the Squad is the creation of a Soldier Integration Facility on Fort Belvoir as part of the Close Combat Force Enterprise. The SIF will operationalize technologies. COL Troy Denomy will be in charge of the SIF, referring to it as a collaboration tool even though it’s a facility. It should open 1 October and will become pivotal for every PM shop at PEO Soldier as well representatives from others.

But even before the SIF gets their hands on it, a new concept begins at the Soldier/Squad Performance Research Institute (S2PRINT) at Natick and are then refined at the SIF. Once they’ve come up with a solution, they’ll work closely with the experimental force at the Maneuver Battle Lab to prove it out.

PEO Soldier plans to be their own integrator, including coders on the team. The SIF will also include a business office to work with industry. General Potts envisions this office will help smaller companies work with larger companies, write awards, or purchase IP outright. They hope to set aside $1 million to get this effort moving. They’ll leverage OTAs, BAAs and other collaborative acquisition tools to invigorate solutions.

Down In The Weeds

“Obviously, a big challenge is power,” General Potts related, “there are too many batteries.” He discussed the upcoming Next Generation Weapons. They will power themselves with a powered rail which also moves data and the rail will run all of the electronic enablers on the weapon.

Another issue is the proliferation of communications devices. Currently, only three Soldiers per Squad have a radio. As IVAS is fielded, every Soldier in a Squad will have a data radio with IVAS. Moving from 128 bit to 256 bit encryption Secure Ultra Wide Band to move data around the Squad in a secure, but unclassified network. The end user device will be replaced by a “puck” but it will still rely on ATAK as the software environment.

This led the discussion to software management. The Army plans for a single ATAK software update per year across the enterprise, vice the four SOCOM currently accomplishes, but that decision is a function of organizational size.

In one of the boldest moves, they’re setting up a marketplace for apps to allow Soldiers to customize their software load based upon mission. The vision is that it works in a similar fashion to a phone app stores like iTunes. This concept will reward developers based upon actual use rather than the current model which creates software which may or may not be used. Under the developmental name Watchtower, the marketplace is in beta testing with an initial roll out in Q1 20 and FOC Q4 20.

More To Come

After he wrapped up with industry, General Potts and his team spent a few monitored with the media. He related that the creation of the SIF isn’t the only organizational change coming to PEO Soldier. We’ll see some renaming of the Program Manager shops to better describe their roles and additional capabilities will be added to the team once a full mission analysis is completed.