Big things can have small beginnings, and small things can make a big difference – like the Small Tactical Universal Battery (STUB). This new family of standardized batteries for handheld and portable electronic devices is generating a lot of interest. Come see what it’s all about at AUSA next week!

The Small Tactical Universal Battery (STUB) series features a common mechanical and electrical interface and the latest USB Power Delivery (USB PD) and Programmable Power Supply (PPS) fast charging technology. Created as a family of 8 different capacities/sizes ranging from 15-80W, the STUB series is designed for dependability in harsh operational environments and provides a scalable power supply that can be shared across platforms and devices.

Currently progressing well through rigorous acceptance testing, the STUB series will help to reduce the Warfighter’s battery burden and improve operational capability and interoperability at the tactical edge.

While you’re at the EXO Charge, you can also learn about other mission-ready power solutions we’re developing for the modern Warfighter as well – such as:

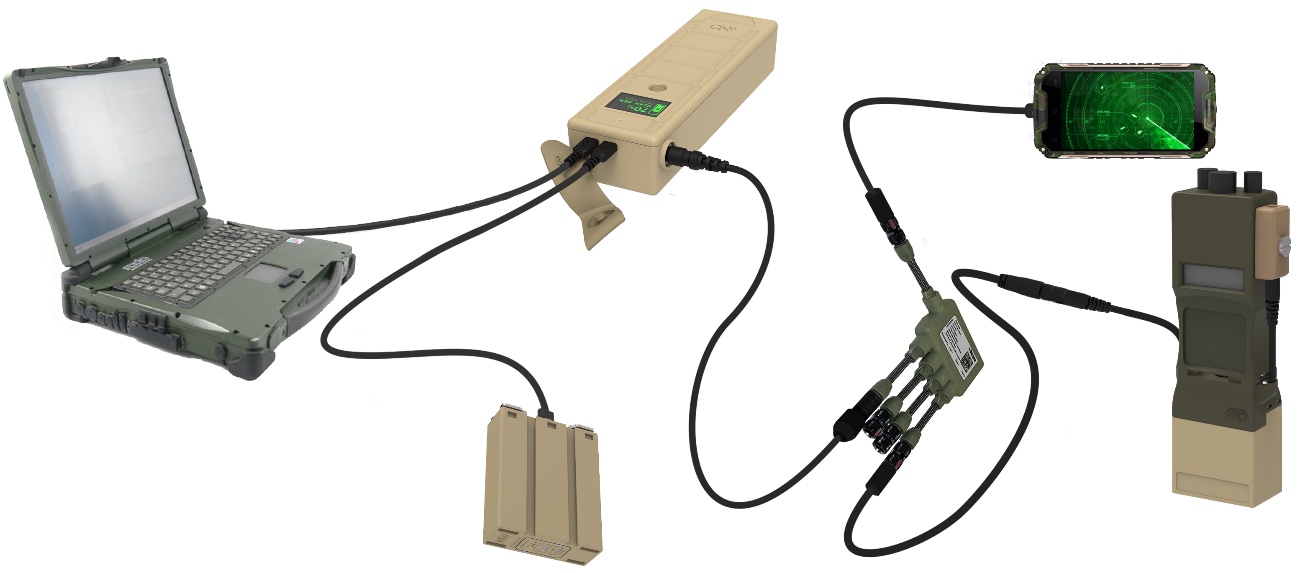

Augmented Power Pack (APP) – a fully ruggedized 300Wh power bank that delivers multi-voltage support (5V-20V) and is specifically designed for operational use in austere environments. With the energy capacity of 2 CWBs, the APP can charge multiple devices simultaneously using USB Power Delivery (USB PD) and Programmable Power Supply (PPS) fast charging technology via its two USB Type C ports. The APP also features a standard Nett Warrior connector for additional, legacy-system compatibility and interoperability. Designed to be tough, reliable, and easy to use in all conditions, the APP also features an NVG-compatible display screen.

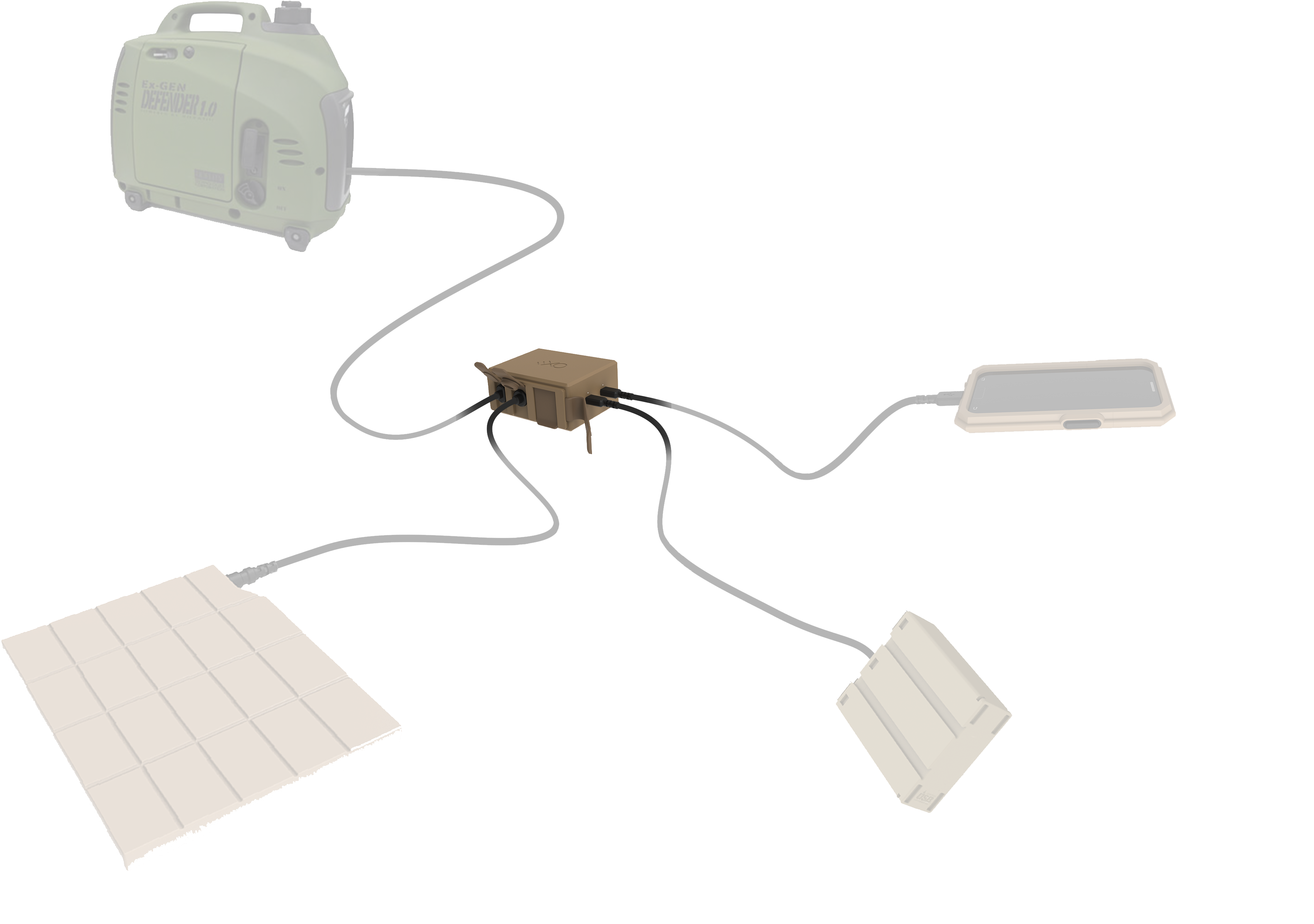

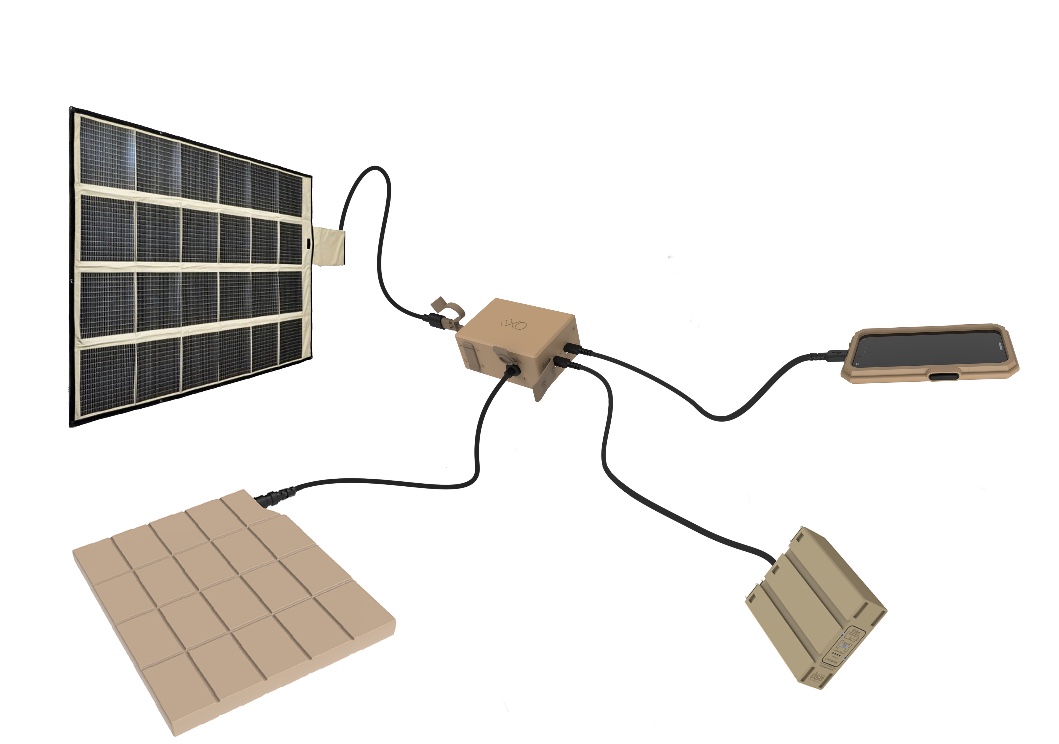

Rugged Auxiliary Charger (RAC) – a small rugged 300W GaN charger, equipped with SAE and Nett Warrior connectors, as well as 2 USB-C ports. The RAC can charge multiple devices or batteries simultaneously through the Nett Warrior and USB-C connectors, and/or can be used as a power adapter for the UBC bulk charger. The RAC features USB Power Delivery (PD) and Programmable Power Supply (PPS) on the USB-C ports for fast charging the STUB series of batteries and COTS devices.

Building on the company’s 30+ year track record in the commercial mobile technology industry, Xentris Wireless created the EXO Charge division specifically to address the needs of next-generation portable power solutions for military applications.