ABERDEEN PROVING GROUND, Md. — Army researchers are exploring new ways to keep Soldiers’ electronic devices powered during extended missions by using wearable fuel cells for on-the-move battery charging.

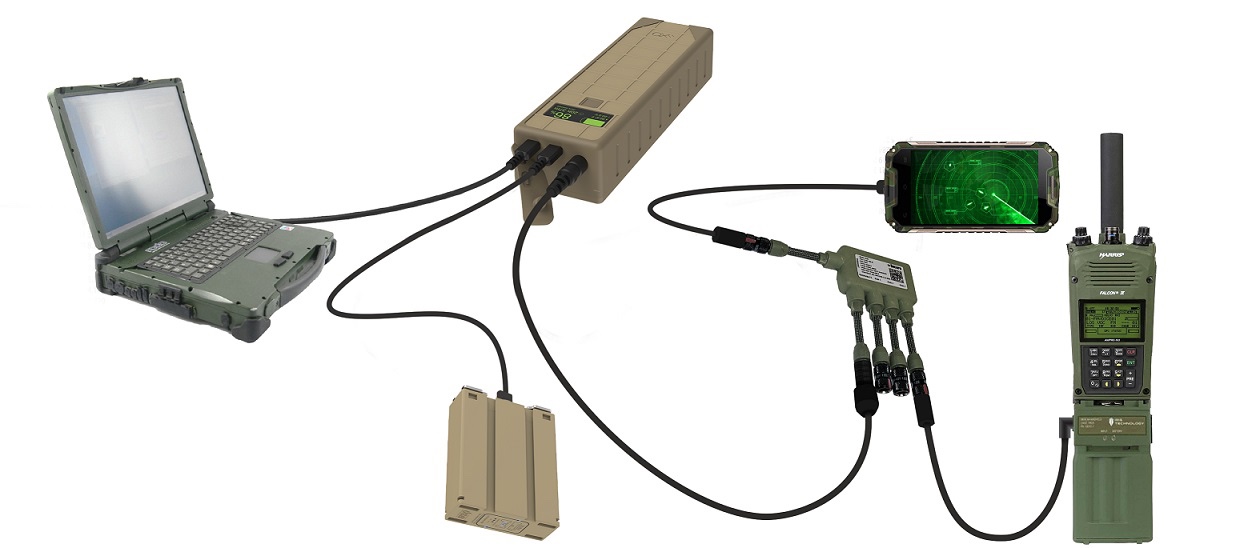

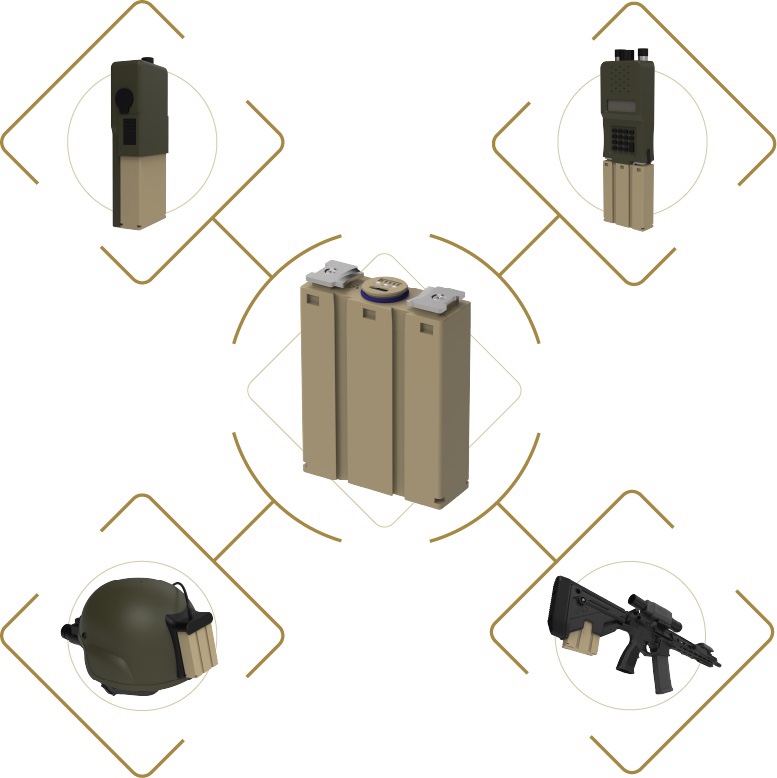

As the Army continues to modernize the force with high-tech Soldier-worn and handheld equipment like radios, GPS, night-vision devices and weapons, the energy demand is continually increasing.

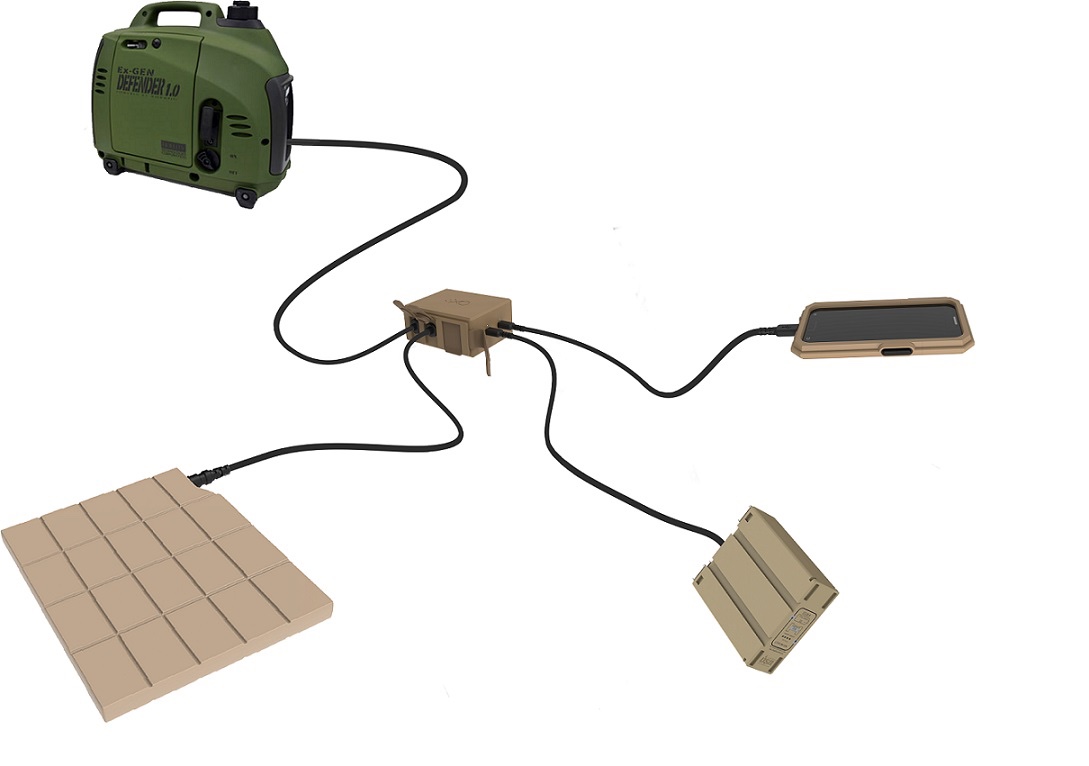

Engineers are working on optimizing the power density and efficiency of emerging fuel-cell based power generation technology when operated with packaged fuels as well as commonly available substitutes such as windshield washer fluid.

Army Futures Command (AFC) is leading work on the Soldier Wearable Power Generator (SWPG) that enables on-the-move charging, thus reducing the number of batteries required to be carried.

“We’re aiming to deliver a simple, easy-to-use way for Soldiers to extend battery life and keep moving in the field by developing wearable fuel cells,” said Shailesh Shah, a chemical engineer with the Command, Control, Communications, Computers, Cyber, Intelligence, Surveillance and Reconnaissance (C5ISR) Center — a component of AFC’s Combat Capabilities Development Command (DEVCOM). “Enabling fuel cell operation on windshield washer fluid already in the Army’s supply chain avoids the need to set up a logistics re-supply of custom fuels. The SWPG simultaneously reduces dependence on logistics for battery re-supply.”

The C5ISR Center’s research aligns with the Army’s renewed emphasis and interest in fuel-cell power generation for supplying power to dismounted Soldiers, according to Shah. Technology in the industry has improved significantly in the past 10 years in terms of size, weight, noise, thermal signature reduction, improved modularity and mounting systems.

Adding wearable fuel cells to the Soldier system enables users to charge the currently fielded thin, flexible Conformal Wearable Battery (CWB) worn on vests as a central power source for electronic devices. The fuel-cell research complements the C5ISR Center’s concurrent work to modernize the CWB with advanced materials.

Researchers are continuing SWPG design modifications to improve performance of the prototypes with an emphasis on size and weight reductions, according to Christopher Hurley, chief of the Center’s Tactical Power Branch. Soldiers on 72-hour missions could save 12 pounds in battery weight under normal power draws with current prototypes.

Additional organizations providing support are the Army’s Project Manager Integrated Visual Augmentation System, DEVCOM Soldier Center, the FBI and the National Defense Center for Energy and Environment.

“A key to enhancing our fuel-cell development is placing different prototypes in the hands of Soldiers during field exercises,” Hurley said. “C5ISR Center engineers have been side-by-side with Soldiers to gain feedback during the Army Expeditionary Warrior Experiment in 2020 and 2021 with plans for 2022. The Soldier touch points are an invaluable resource in our development process so we can immediately turn around and incorporate their evaluations into our hardware systems.”

By Dan Lafontaine, DEVCOM C5ISR Center Public Affairs