CAMP BUEHRING, Kuwait — Improvised Explosive Devices (IEDs) were a deadly threat during Operation Iraqi Freedom and Operation Enduring Freedom, causing the majority of casualties in both conflicts. IEDs remain a threat today for coalition forces in Iraq and Syria during Operation Inherent Resolve.

The U.S. military developed several countermeasures to protect both mounted and dismounted service members from this threat.

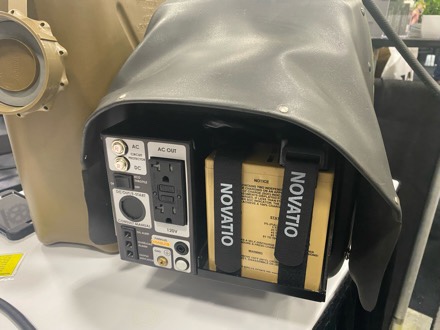

Counter Radio-Controlled Improvised Explosive Device Warfare (CREW) systems provide protection by jamming signals that detonate radio-controlled IEDs (RCIEDs). The Duke Version 3 and CREW Vehicle Receiver Jammer (CVRJ) vehicle-mounted systems, and the Thor III and MODI II dismounted systems, have been effective in protecting service members from the RCIED threat.

Since 2010, an Electronic Warfare Operations (EWO)/CREW system course had been taught by contractors at Camp Buehring, Kuwait. The class was offered to service members from newly arrived units that employ CREW systems in convoys and on patrols. However, due to the COVID-19 pandemic, the class has not been taught for the past 10 months.

“Due to travel restrictions, we were unable to offer the same level of training,” said Capt. Jefferson Wilkes, Officer-in-Charge (OIC) for the U.S. Army Central Command Readiness Training Center (ARTC). ARTC is responsible for providing training support to coalition tenant units in Kuwait.

“The EWO/CREW Specialist Course allows Soldiers who rely on CREW systems, as they come in theater, to stay proficient in the operation and maintenance of the systems to increase survivability of their units across the AOR (Area of Responsibility),” Wilkes said.

Illinois National Guard Soldier Chief Warrant Officer 2 Anthony Meneely and Florida National Guard Soldier Chief Warrant Officer 4 Douglas Montgomery are Electronic Warfare Technicians who arrived in theater in April 2021 with Task Force Phoenix—a combat aviation brigade responsible for full-spectrum aviation operations for Operation Spartan Shield and Operation Inherent Resolve.

Meneely, Montgomery, Electronic Warfare NCO Sgt. Ismael Pulido and OIC Maj. Jeremy Tennent are Task Force Phoenix’s Cyberspace Electromagnetic Activities (CEMA) cell. They are responsible for ensuring that friendly radio-wave emitting equipment is safe and secure, and they advise the Task Force’s command staff on adversary electromagnetic jamming.

After they arrived in theater, they soon learned that the EWO/CREW class was not being taught.

“This equipment is vital on a contested battlefield where RCIEDs are a threat,” Meneely said. “Soldiers were not getting proper training for the CREW devices for their vehicles that were headed north.”

Meneely and Montgomery had the skills and expertise to teach the class. They contacted Capt. Wilkes and Lt. Col. Willard Lund, director of the Directorate of Plans, Training, Mobilization and Security (DPTMS). DPTMS is responsible for all training in Kuwait. Meneely, Montgomery and Tennent made an offer to Wilkes and Lund to restart the class, update it and teach it.

“They were fully supportive,” Meneely said of Wilkes and Lund. “They’ve been helping us insurmountably with materials, equipment and general support.”

“Chief Meneely, Chief Montgomery and Maj. Tennent identified a training gap along with a resourcing gap,” Wilkes said. “They worked with us to make connections across the AOR to stand up a new program. As a result, they were able to update all of the systems and offer training for them.”

Meneely, Montgomery and Pulido, a California National Guard Soldier, welcomed their first class at Camp Buehring on July 12. Tennessee National Guard members Spc. Curtis Hicks and Staff Sgt. Thomas Daniel, from the 1-181st Field Artillery Battalion, and Virginia National Guard Soldier Staff Sgt. Richard Recupero, from the 29th Infantry Division, were the first graduates of the four-day course.

“We taught them the fundamentals of electronic warfare and the 10-level maintainer tasks for CREW systems,” Meneely said. “Upon completion of the school, the CREW maintainers can load, operate, troubleshoot and fix deficiencies in the systems. They will go back to their units responsible for ensuring all their CREW systems will be mission capable.”

Staff Sgt. Daniel said the course gave him vital training on the CREW systems that his battalion employs. “Our security force rolls out with these systems,” he said. “We’ll be in charge of doing the testing and reporting for the systems for the battalion.”

“I think the class went well,” Montgomery said. “We’re going to continually adjust the course and update it based on assessments, feedback and emerging threats.”

Meneely and Montgomery said they will be hosting additional classes as needed for incoming units. They also plan to establish a counter unmanned aerial system (CUAS) academy at Camp Buehring.

Story by MAJ Jason Sweeney, 40th Combat Aviation Brigade