For many Soldiers, the thought of visiting their local Central Issue Facility invokes certain feelings: anxiety and frustration to name a couple. This might change soon for the Soldiers of Fort Stewart-Hunter Army Airfield as the CIF experience is transforming to make the process easier for the warfighter.

Transitioning to appointments

Transitioning to a modern storefront program, Soldiers are now able to schedule appointments online for their CIF turn-in and exchanges.

“After a few weeks of testing the system with the Marne Reception Center, the appointment system is now live. It lets Soldiers coordinate directly with the local CIF for times that work for them, and then the facility will get a daily report of how many Soldiers are coming in,” said Lt. Col. Chad Moniz, the battalion commander of the 406th Army Field Support Battalion-Stewart who is responsible for the Fort Stewart and Hunter Army Airfield CIF.

“The system will enable a better experience for the Soldier, while maintaining a forecastable schedule for the CIF staff who still need to be ready to respond to real-world surge requirements,” he said.

“We still have the ability with the appointment system to keep Soldiers informed,” Moniz continued. “If we were planning to support a real-world deployment surge, massive plate exchange or inventories, we can change it in the system so those times will show as unavailable in live time. This will reduce lines or Soldiers having to find out in person.”

Appointments will be made in 15-minute increments. The AFSBn team recommends Soldiers arrive 10 minutes early to allow for accountability. The system is set up to accommodate eight people every 15 minutes.

For now, the new program has focused times targeting different needs. Soldiers from the Marne Reception Center will be accommodated daily until 10:00 a.m. From 10:00 a.m. to 2:30 p.m., CIF has open appointments for any service. From 2:30 -3:30 p.m., the CIF will continue to have walk-in open time to enable Soldiers that do not have appointments or who may not have access to common access card-enabled computers to make the appointments. Appointments can be made up to two weeks prior to the requested date.

Moniz explained that the appointment program will send Soldiers an email once the appointment is booked. It will also notify the CIF of what services Soldiers are requesting, whether it is for exchanging equipment, receiving new issue, or turning in old equipment.

Overhauls to adjust to transformation

While the modernization will result in welcomed improvements, the transition caused some delays for CIF customers in August and September. Completing a 100% inventory of the multi-million-dollar property book between the two installations was required because of a key personnel change occurring at the same time as the modernization transition, which was further exacerbated by impacts from the COVID-19 pandemic.

“We are a very customer focused organization, with the majority of our employees being retired military,” said Nia Landry, deputy commander of the 406th AFSBn. “They take great pride in providing services for the Soldiers, but we did run into somewhat of a perfect storm.”

Landry said that an accountable officer unexpectedly retired during the key implementation of several phases of the modernization process, forcing the CIF to conduct a 100% accountability inventory of both sites. This, combined with a large surge of Soldiers with PCS orders, caused backups in the system.

“It was not our intent in any way to inconvenience Soldiers and their families,” Landry said. “Moving forward, we have several things in place that will improve your experience at CIF, and we always welcome suggestions as we strive to get better.”

Throughout the inventories, the average throughput did not decrease. The facility on average services 100 Soldiers in the morning, and 100 in the afternoon. As a result of an uptick in approved PCS orders following a long pause with COVID-19, the Fort Stewart and HAAF facilities surged to support more than 300 customers a day.

While the inventory took place, CIF also reorganized the entire warehouse and corrected internal processing issues. The facility also divested a large amount of inventory by moving equipment down to the unit level.

“Just like a company [executive officer] might prepare for their commander’s inventory layout several months in advance, inventory prep and accountability takes time,” said Moniz.

“Now expand that to a property book going through reduction from $98 million on hand and getting it down to $72 million,” he said. “We also packed and readied for shipment another $30 million just at Fort Stewart. HAAF is expected to reduce from $14 to only $1.5 million.”

The two CIFs support missions for not only the 3rd Infantry Division, but also a Ranger battalion, and other unique tenant units across both installations. They will continue to reduce stock by another half over the next few months as they send items to locations as directed by disposition instructions.

“We were sacrificing the time now to better support Soldiers later by improving our processes,” said Kevin Lewis, the supply and services division chief for the CIF facilities.

He explained tenant units like those in Special Forces will eventually go to systems managed by their supply sergeants to do more direct ordering. This process will solve more problems at the unit level and save Soldiers a trip across the base while also reducing strain on CIF.

Soldiers can also expect to get more of their equipment issued by their own supply rooms as fewer items are kept on hand at CIF. The facility will still handle exchanges and turn-ins. However, if units are exchanging something that is not typically stocked in the facility, it will have to be ordered.

Planning for future CIF visits, PCS moves

As thousands of 3rd ID Soldiers redeploy from Europe and South Korea in 2021 along with traditional PCS moves, it’s important to relearn what most career Soldiers already know: always try to clear CIF first.

While the experiences this summer were unprecedented, it was a good reminder for Soldiers to leave extra time in their clearing process for CIF in case they are missing items or if their equipment needs further cleaning.

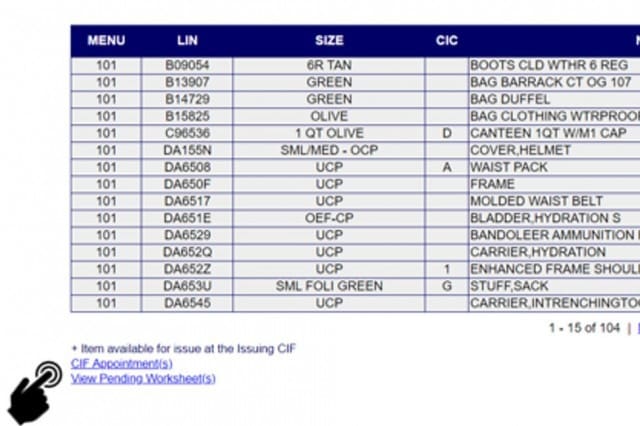

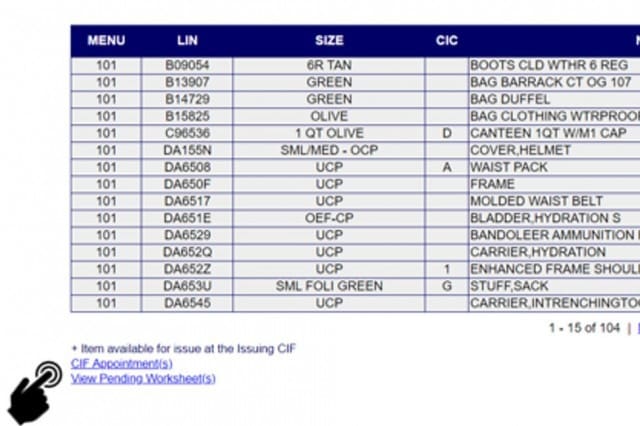

“The best way to be prepared for CIF is to check your online Organizational Clothing and Individual Equipment record,” Moniz said. This will tell you exactly which items you can carry with you, and which ones need to be turned in.”

“For Soldiers at Fort Stewart/ Hunter Army Airfield who are in a PCS status, from now on most will only turn-in their [Enhanced Small Arms Protective Inserts] plates,” he said. They can carry forward their OCIE gear with their household goods through the transportation personal property office.”

ESAPI plates are turned in to allow them to be scanned for any possible deficiencies and ensure they can protect their wearer.

Soldiers can find their individual clothing record at ism.army.mil/ism/SelfServiceServlet?nav.nav_id=ssMyClothing and should conduct a personal inventory prior to arriving at CIF to ensure they have everything they need.

While the appointment system is now open, clearing papers and orders are still required for service. To make an appointment, click on the link labeled “CIF appointment” in the bottom left corner of the individual’s OCIE clothing record.

By LTC Lindsey Elder