The SPM-622 Squad Power Manager Data Log capability allows small units to measure how much battery power they are actually using, so they can optimize their logistics, resupply, and mission loads – and reduce their Battery Burden.

The Data Log function of the SPM records:

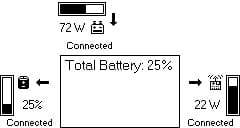

• What devices are plugged into which ports of the SPM

• The voltage, average current and maximum current at each port in use

• The state of charge and temperature of any connected battery / batteries

• A real-time-stamp that includes the date and time of the entry

• Any errors or user alerts

The data log is stored in such a way that it does not disappear if power is lost, and the storage capacity is large enough to keep weeks-worth of usage data. Finally, data logging occurs automatically, but the standard settings can be overridden in order to capture specific or unique data of interest. Once collected, the data log can then be uploaded to a computer and displayed and analyzed using typical tools such as Excel, etc.

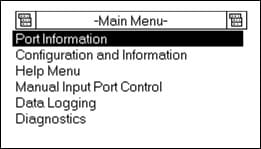

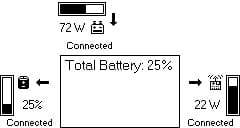

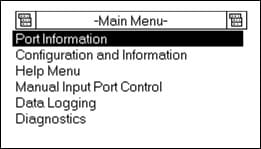

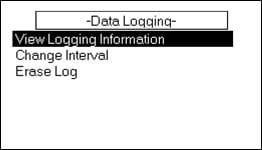

To access the data log function of the SPM-622, the operator uses the four buttons along the bottom edge of the SPM-622. From the main screen, press the right arrow Button once to enter the main menu. Once at that screen the operator will see the following display:

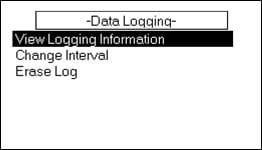

Selecting the data log option from the menu selection allows the User to view how much data has already been captured, or to change the data capture intervals. Pressing ‘Erase Log’ will delete all data in the log file.

If power usage data for a particular mission is desired, the User should clear the SPM’s data log before departure and then download the data after the mission is completed. As an example of the benefit of analyzing such data; a SOF unit deployed in a non-permissive environment was able to reduce the battery weight of their mission loads by over 30% – and still maintain full operational capability of their critical electronic equipment.

If you need further assistance, refer to the SPM-622 User Guide or contact Support@Protonex.com. Visit www.PTXnomad.com for further info about the wide range of applications and equipment supported by the SPM-622 Squad Power Manager.