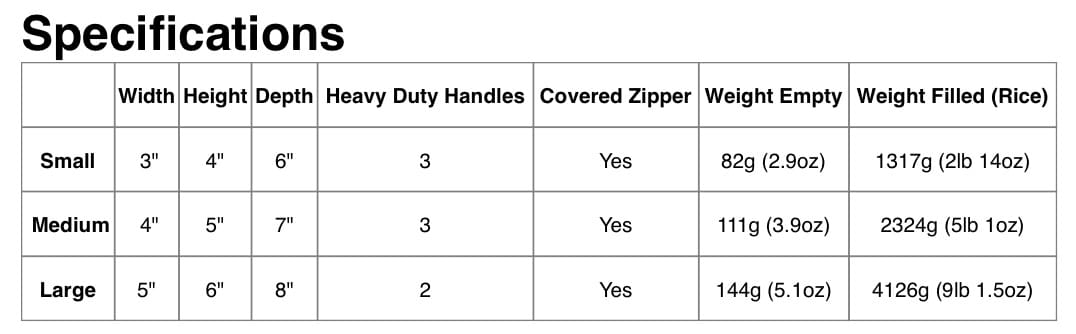

Lockhart Tactical’s shooting bag set is made from 1000D Cordura and comes in sets of three sizes.

Each bag features two or more heavy duty reinforced grab handles. The small and medium bags both have a third hand loop, keeping this bag secured in your hand while used as a rear buttstock rest.

Each bag also has dual adjustable shockcord lacing that can be tightened to firm up the bag and adjust for height. This also allows you to fill your bags half way, tighten up the sides and have an even more lightweight and compact setup.

The zipper teeth are large, non-rusting,smooth sliding and quiet while opening and closing. A comfortable rubberized pull tab is attached for ease of grip with bulky gloves on.

Offered in Black, Desert Tan, OD Green, with

Wolf Grey Coming Soon.

www.lockharttactical.com/prsbags

Bravo Company brings some great info from Larry Vickers.

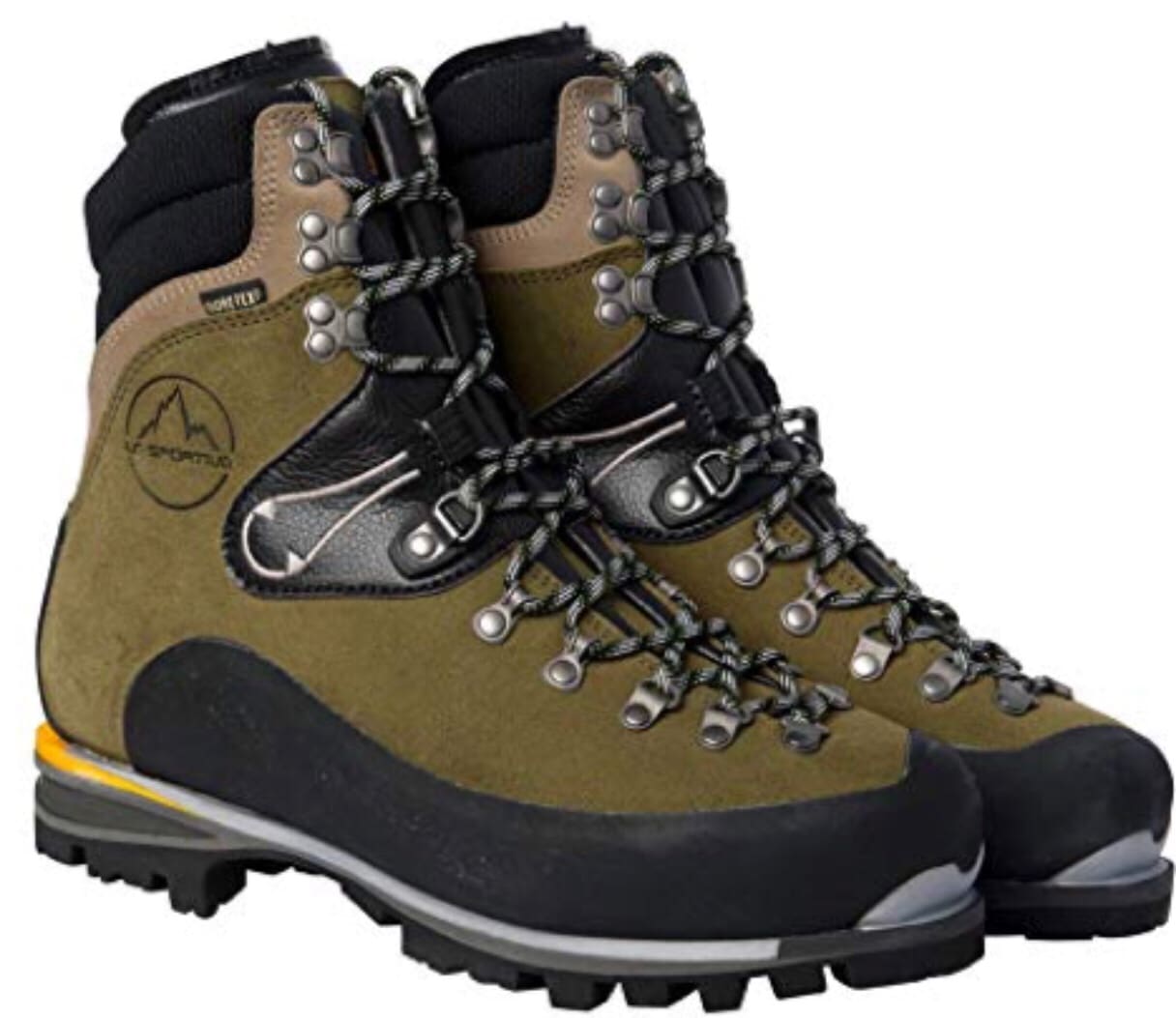

When you are operating high in mountainous terrain you need a boot that you can rely upon. One that you can confidently climb in and move aggressively over the most demanding ridges and mountains.

Light, technical, B3, crampon compatible boot it comes in at 1.750g (3.85lbs) for a pair of size 42 EU. Made with 2.8mm Idro-Perwanger leather it is robust and hard wearing. With its Gore membrane it provides waterproof and breathable protection for your feet. This combination of features makes it the ideal boot for mountain troops operating far in advance of conventional forces in all conditions be it snow or arid.

La Sportiva have a long tradition, starting in 1928, of building outstanding boots and making products that you can depend upon in the most extreme circumstances. Based in the Dolomites they are ideally situated to design and build the best.

For more information get in touch by email on international@brigantes.com or for UK customers tribe@brigantes.com. www.brigantes.com

It’s pretty straight forward. It’s a PVC morale patch, depicting a kitted out Crye Precision AirFrame Helmet. Offered in two colors.

www.griffonindustries.com/product_p/shot2018-pvc-patch

Throughout the 2017-2018 legislative session, AKTI has had numerous successes in easing burdensome restrictions on knife owners throughout the nation, including a repeal of the automatic knife prohibition in Colorado and Michigan. In addition, AKTI has continued its work to protect lawful knife owners traveling through the current patchwork of state and local knife laws with the introduction of the Interstate Transport Act.

The organization has worked closely with legislators and staff in the United States Congress to advance its signature federal legislation, which is led by Senators Mike Enzi, R-WY, and Ron Wyden, D-OR, and currently has eight additional bipartisan co-sponsors. These co-sponsors include: Senators Steve Daines, R-MT, Martin Heinrich, D-NM, James Risch, R-ID, Joe Manchin, D-WV, Jeff Merkley, D-OR, Mike Crapo, R-ID, Tom Udall, D-NM, and Tammy Baldwin, D-WI.

Under current United States code, lawful gun owners are allowed to transport firearms that are legal in both a traveler’s state of origin and state of destination, even if they will pass through jurisdictions that would not permit the firearms, provided they are properly stored and in accordance with all federal restrictions. This protection was created in 1986, when Congress passed the Firearms Owners Protection Act (FOPA). Prior to this legislation, gun owners had no way to legally travel with their firearms through states and localities that had more stringent laws. This law empowers firearm owners to travel more freely, while not restricting states’ ability to regulate the firearms that are carried within their borders.

“In Wyoming, we understand that knives are an essential tool for folks, whether they are for hunting, ranching or for everyday use,” Enzi said. “I am glad the committee passed this legislation, which would allow law-abiding knife owners to finally be able to travel across the country without fear of breaking the law. I am hopeful that the Senate will act quickly to pass this common-sense legislation.”

The Interstate Transport Act is a continuation of AKTI’s efforts in the US Congress since 2013. Over that time, AKTI has heard repeatedly from knife owners who have questions about the confusing and varying laws in locations they are visiting or through which they are planning to travel. Since AKTI’s goal is to ensure that law-abiding citizens have knowledge and confidence in their ability to carry the tools they use in their daily lives, we got to work.

“Since we were formed in 1998, AKTI has worked to systematically address what we saw as outdated, confusing, and unfair laws both in the states, and at the federal level,” said CJ Buck, AKTI President and CEO of Buck Knives, Inc. “Our goal is common sense knife reform, and in recent years we have had success fighting for changes in multiple states, to the benefit of the consumer. We’re extremely encouraged to see the Senate Commerce Committee pass the Interstate Transport Act, and we are highly optimistic that the Senate will soon pass the legislation and send it to the House for their approval. We are proud to be working with a bipartisan group of legislators who share our commitment to common sense solutions, and we look forward to passing this important reform into law. We thank Senators Enzi and Wyden for their hard work on the Interstate Transport Act, and look forward to working with them to get it across the finish line.”

For more information, visit www.AKTI.org.

We celebrate our nation’s independence every July 4th, but the creation of America didn’t happen in just one day.

Colonists started fighting the crown in April of 1775, declared independence in July of 1776, and fully established that sovereignty in September, 1783, with the signing of the Paris Treaty. It wasn’t until September of 1787 that we finally created a proper framework of government. Even then, that constitution didn’t come into force until 1789.

What’s more, we didn’t go it alone. France was instrumental in our revolution against England here in the Americas, while the war grew and spilled over into Europe, and even the sub-continent of India.

We like to wrap it all up neatly into a single date, so often pointing to this painting commemorating the event, but our fight for independence took over eight years of conflict and six more of politicking. It’s an amazing tale and well worth researching.

• New space endeavor draws on company’s unique and diverse history of innovation and high-altitude drone flight experience

• Drone prototypes have passed rigorous tests in simulated Mars atmosphere

• Final Mars-bound helicopter now in production at JPL

MONROVIA, Calif., July 3, 2018 – What does a company do when its trailblazing and diverse innovations for nearly half a century have redefined how the world drives and flies? When its many technological “firsts” include the first practical electric car, flying the Nano Hummingbird drone, record-setting, solar-powered aircraft flights in near space, and reshaping the battlefield with portable, hand-held, tactical drones and loitering munitions?

It takes on another world.

At a briefing held Wednesday at New York City’s NASDAQ Marketsite, AeroVironment, Inc. (NASDAQ: AVAV) revealed its critical role in collaborating with NASA’s Jet Propulsion Laboratory (NASA/JPL) in Pasadena, Calif. to build the drone helicopter recently selected by NASA/JPL’s Mars Exploration Program, and displayed a model of the Mars Helicopter, which is planned to fly on Mars in less than three years.

“AeroVironment’s deep, rich and diverse history of innovation combined with our experience with near-space aircraft like Pathfinder and Helios make us uniquely suited to collaborate with NASA and JPL on this historic, interplanetary venture,” said AeroVironment President and Chief Executive Officer Wahid Nawabi.

Flying at nearly 100,000 feet on Earth is much like flying on the surface of Mars – same air density – so AeroVironment used airfoil design principles and simulation tools the technology company learned from record high-altitude flights and incorporated them into the Mars helicopter design.

“The Mars Helicopter effort also benefits from the ultra-lightweight and ultra-high-precision methods integral to our nano projects that have been developed in our MacCready Works laboratory, where we’ve assembled a dedicated team of the industry’s brightest and most experienced thinkers to solve some of today’s greatest technological challenges,” Nawabi said.

AeroVironment first developed subscale Mars helicopter prototypes to test and demonstrate the feasibility of lift in the thin Martian atmosphere. Then in May 2016, AeroVironment delivered to NASA/JPL a Mars Helicopter rotor and landing gear prototype that was integrated with a JPL-developed controller and demonstrated free flight in a simulated Mars atmosphere, proving that it is possible to fly on the Red Planet. Next, AeroVironment delivered major helicopter subsystems in the fall of 2017 for integration into Mars-representative engineering development models. JPL built two Engineering Development Model Mars Helicopters, integrating the AeroVironment rotor, landing gear, fuselage shell and solar panel substrate together with JPL-developed fuselage composed of flight avionics, onboard power, telecom, flight control and sensors into two models.

One of the development models was used for flight demonstration in JPL’s large 25-foot space simulator, and the other for environmental testing, including thermal tests to ensure the vehicle can endure the frigid Mars nights, and vibration tests to make sure it is rugged enough to survive launch. Both vehicles passed the rigorous tests, paving the way for the development and fabrication of the final, Mars-bound version.

AeroVironment is currently building the flight versions of their subsystems which will be integrated with other subsystems into the vehicle that JPL is building. The plan is for JPL to then install the finished Mars Helicopter into the Mars 2020 rover for its ride to a Martian landing site, still to be determined.

The Mars Helicopter project is led by NASA JPL with team members across JPL, AeroVironment, NASA Ames and NASA Langley. The AeroVironment team has worked closely with NASA rotorcraft experts at the NASA Ames and Langley research centers and with JPL electrical, mechanical, materials, vehicle flight controls, and systems engineers. AeroVironment’s contributions to the first Mars drone include design and development of the helicopter’s airframe and major subsystems, including its rotor, rotor blades, hub and control mechanism hardware. The company also developed and built high-efficiency, lightweight propulsion motors, power electronics, landing gear, load-bearing structures, and the thermal enclosure for NASA/JPL’s avionics, sensors, and software systems.

The press briefing featured high-impact visuals and models of many of AeroVironment’s innovations, including the Snipe™ nano drone – the latest tactical UAS innovation from AeroVironment that provides today’s defenders with critical information whenever and wherever it is needed – and the Switchblade® Lethal Miniature Aerial Missile System (LMAMS). AeroVironment recently received Switchblade orders from the U.S. Army and U.S. Marines Corps through Urgent Needs Statements.