Job Description:

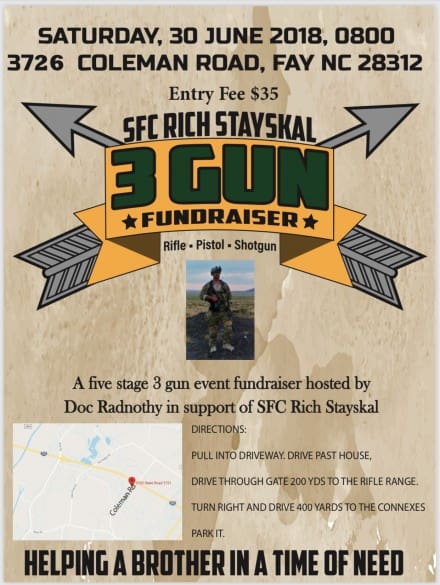

The Illustration and Graphic Designer will be a member of the in-house marketing team, which is responsible for creative development and execution of internal and external marketing communications and branding materials. The scope of work will include projects that reflect Magpul’s roots in firearms and shooting sports, with a mix of action sports, humor, and general pop culture sensibility. The team creates a wide range of products, and this designer will be focused on providing illustration, animation, and graphics for videos and social media products, apparel, company websites, email newsletters, and assorted print materials.

Essential Duties and Responsibilities:

• Interact clearly and confidently with internal teams to determine their visual communication needs, present ideas, and take direction from start to finish.

• Design and create high quality full-performance animations and animated backdrops for media.

• Create sketches, artwork, and illustrations for a wide range of media.

• Produce apparel design graphics.

• Create representation graphics and custom typography, as well as color palette and photography.

• Produce web design graphics that can be reproduced by web developers.

• Translate or re-envision artistic works and vintage or historical images.

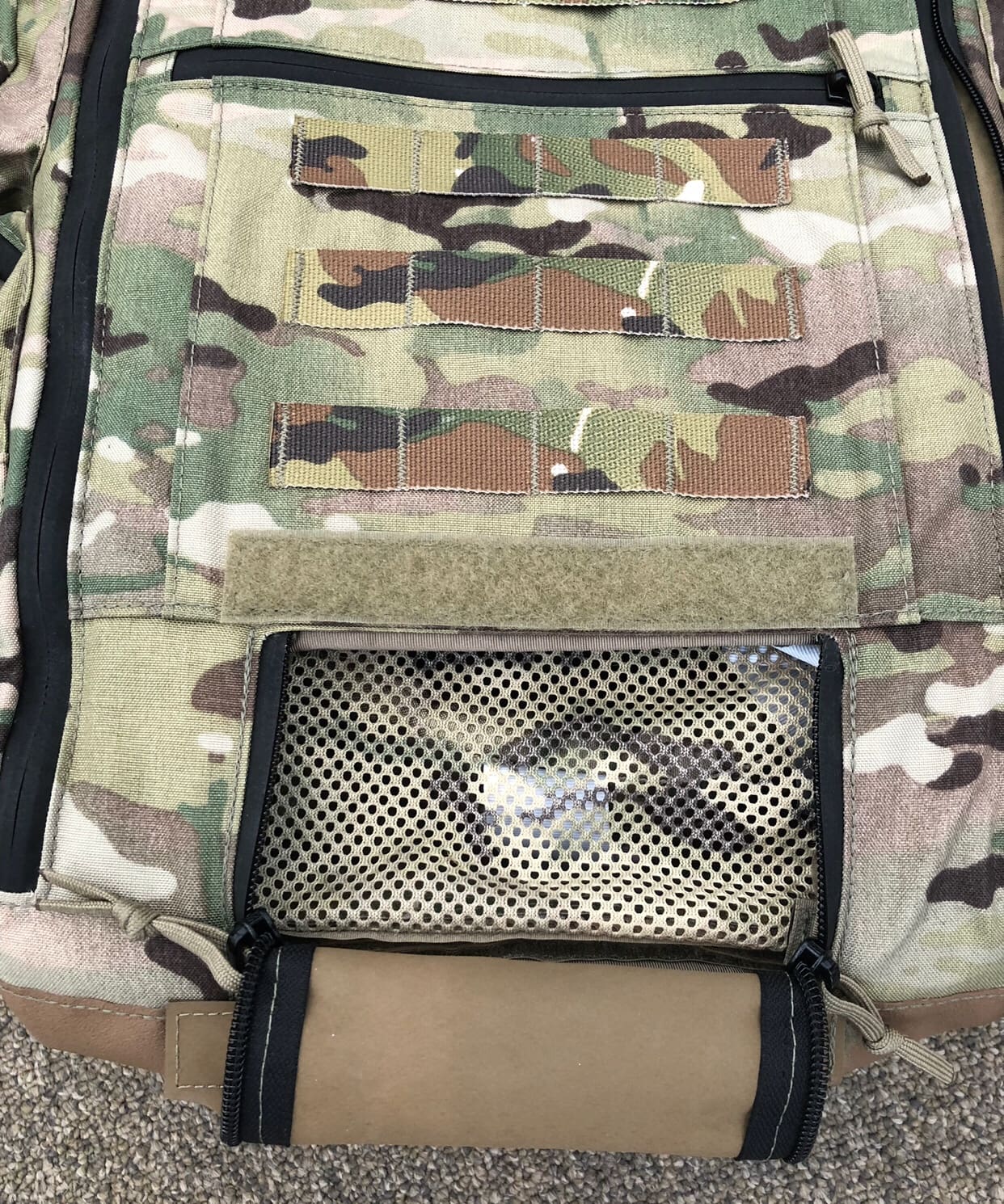

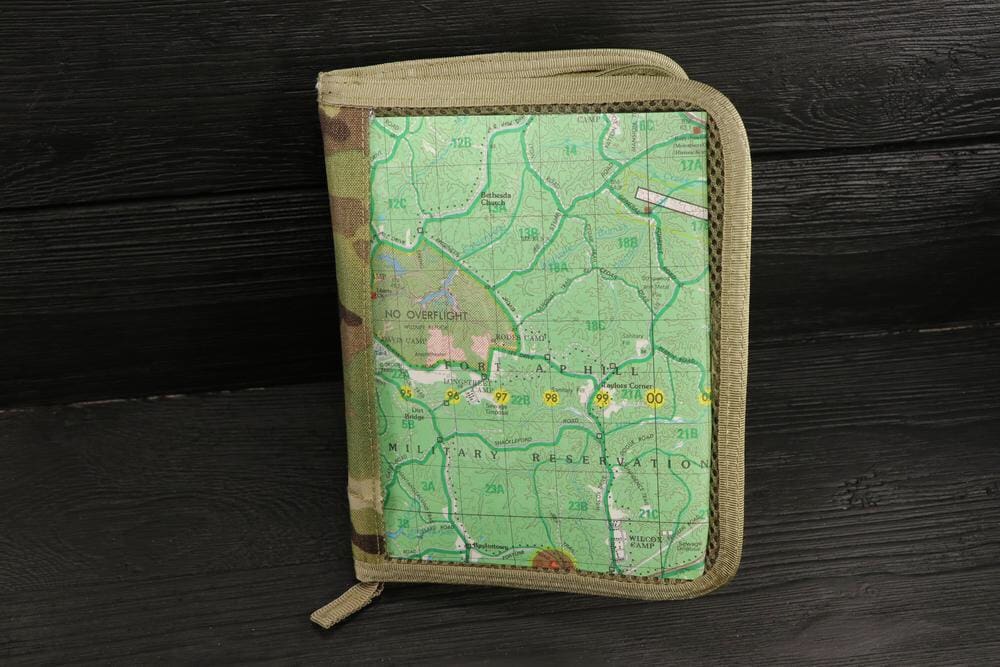

• Produce product graphics.

• Domestic travel up to 10%.

• Other duties as assigned.

Qualifications:

• Bachelor’s Degree in a related area (graphic design, animation, multimedia design, fine art, film studies or CGI and 3D modeling) or an equivalent portfolio of work demonstrating expertise in the field of animation.

• Strong resume and portfolio that includes any of the following: logo design, apparel graphics design, animation, illustration, and print collateral.

• 3+ years of experience in after effects.

• Experience with motion graphics and 3D rendering capabilities a plus.

• Experience with military, firearms and shooting sports a plus.

• Marketing experience a plus, but not required.

Job Knowledge, Skills and Abilities:

• Strong illustration skills, including expertise in digital pencil, inking, painting and vector artwork.

• Proven experience and advanced knowledge in Adobe Illustrator, Adobe After Effects, Premiere Pro, and Adobe Creative Suite.

• Strong typography skills and knowledge of contemporary design.

Additional:

• Applicants will not be considered unless a portfolio of work is provided.

• This position reports to the Director of Marketing.

• Competitive pay rate commensurate to experience.

• Benefits include medical, dental, vision, life and long-term disability insurance as well as voluntary short-term disability and accident insurance. Additionally, we offer a 401(k) Plan.

• Must be eligible to work in the United States for any employer. The applicant must be authorized to receive Technical Data and/or Technology under U.S. export control laws. Any offer made is contingent on the applicant passing a background check that will include a restricted party screening and, for prospective employees who are Foreign Persons, on the Company obtaining all necessary export licenses. In addition the applicant will be required to pass a criminal background check and drug screening.

Click here to apply.

Magpul is an equal opportunity employer.

Magpul regularly updates their job listings. To keep up with the latest openings, visit www.magpul.com/about/careers.