Knoxville, TN — Qore Performance, Inc. announces the launch of ICEPLATE® Gen 3, the next-generation Medium ESAPI-shaped hard-cell hydration bladder that delivers 70 watts of cooling, 52 watts of heating, and 52.4 fl oz (1.55 L) of drinkable water in a single, plate carrier compatible system.

Now 20% lighter than its predecessor at 10.5 oz empty with 5% greater capacity and dramatically improved multi-curve ergonomics, ICEPLATE® Gen 3 is purpose-built for year-round use by performance-minded military, law enforcement, prepared citizens, first responders, and industrial professionals.

For full conductive thermoregulation and hydration benefits, ICEPLATE® Gen 3 is worn internally of ballistic plates via Qore Performance’s IMS Pro Gen 3 for armed professional applications, or standalone within HiVis thermoregulation vests for industrial safety use.

Powerful Performance:

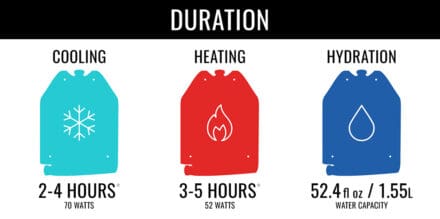

- 70 watts conductive cooling when frozen; 52 watts heating when filled with hot water.

- Delivers 2–4 hours of intensive cooling or 3–5 hours of heating, preventing heat stroke and hypothermia while augmenting human physiology for peak performance.

- As ice melts from body heat, it creates ice-cold drinking water, with the system becoming progressively lighter as this water is consumed.

Features:

- Seamless integration with plate carriers, chest rigs, backpacks, and HiVis safety vests.

- Dual 28-410 fill ports accept ICECAP® Gen 3, Valve Cap, Closed Cap, or standard Coca-Cola/Dasani threads.

- Drinkable variants include SOURCE™ 90 tube, Helix™ bite valve, and ICECAP Gen 3 quick-disconnect for rapid “Hydration As A Magazine” swaps.

- ICEPLATE® Gen 3 is 100% Made in the USA by U.S. citizens from US-sourced FDA-certified, BPA-free HDPE in Iowa.

Since 2016, Qore Performance has been Building A Superhuman Future®—and ICEPLATE® is where that future began. With over 6.5 million operational hours and zero heat injuries, ICEPLATE® redefines what’s possible for professionals across business, safety, and defense. ICEPLATE® Gen 3 turns temperature into a weapon—creating decisive advantages for performance and survival where none existed before.

“ICEPLATE® Gen 3 is the most refined and capable cooling, heating, hydration system we’ve ever developed,” said Austin Pitsch, Marketing Manager of Qore Performance, Inc. “It inoculates users against extreme heat and cold while delivering mission-critical hydration, while scaling effortlessly from individual use to full enterprise and organization deployment.”

ICEPLATE® Gen 3 is available now at QorePerformance.com.