If the impressive signage is any indication, this year’s Warrior East is going to be awesome! But seriously, I peaked inside and there is loads of cool stuff with lots of new vendors as well as the brands we all know and love.

If the impressive signage is any indication, this year’s Warrior East is going to be awesome! But seriously, I peaked inside and there is loads of cool stuff with lots of new vendors as well as the brands we all know and love.

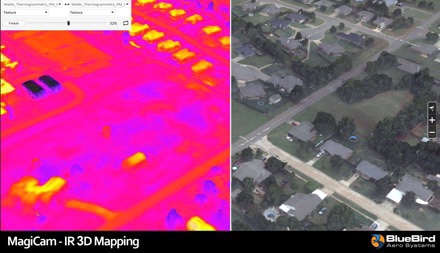

[Hepher Industrial Park, Israel, June 21, 2023] – BlueBird Aero Systems, a leading innovator in unmanned aerial Tactical systems (UAS) technology, proudly introduces MagiCam, a groundbreaking 3D Hi-Rez Large Area Mapping capability integrated with the renowned autonomous UAV, the WanderB-VTOL. This cutting-edge system revolutionizes large-scale mapping operations with its advanced Imaging payload, Smart features, stealthy operation and top-of-the-line actionable products.

MagiCam offers impressive specifications and delivers unmatched performance: It provides a projected footprint of up to 40 km2/hour (2D) and up to 12 km2/hour (3D) when flying undetected at 500 meters altitude, ensuring exceptional speed and efficiency. With a 3.2cm/pixel Ground Sample Distance (GSD), the system guarantees clear and detailed imagery, while its scalable processing time delivers quick results within hours of landing. Equipped with a uniquely designed gimbaled camera, MagiCam scans the area and captures multiple geo-tagged high-resolution images for precise mapping and 3D data. It also excels in detecting and marking changes between sorties, enabling users to track alterations over time, enhancing situational awareness and decision-making.

The mapping mission is planed using intuitive interface and executed autonomously by the UAV, ensuring seamless operation.

In defense applications, MagiCam provides valuable 3D and tactical information for combat units and facilitates target positioning for smart munitions. It enables near real-time terrain and hostile situational awareness, aiding informed decision-making. The system also contributes to battle damage assessment (BDA), operational mission planning, high- accuracy measurement tools, and mission preparation 3D databases. Optional inclusion of IR thermal mapping adds versatility for night operations.

The MagiCam payload* features impressive specifications, including a 103 MP sensor, a 5-look projected image footprint, nadir imaging capabilities, an onboard processing computer, and high-speed storage in an amazing weight of 1500 grams. It supports geo- tagging and includes a calibrated lens for precise data processing.

BlueBird presents a comprehensive tactical mapping solution with MagiCam, combining high-resolution 2D and 3D mapping capabilities with autonomous, simple and undetected operation. The system excels in providing extensive coverage per flight hour, ensuring efficient mapping operations. Equipped with powerful intelligence analysis tools**, MagiCam enables advanced data analysis and interpretation, further enhancing its value.

*Payload developed by WaldoAir from Panama City Florida. WaldoAir is the main supplier of 3D mapping payload for FEMA and the Civil Air Patrol.

**Processing of images, creation of 3D database and the smart tools supported by Skyline Software Inc. software and are used by the US army geospatial centers and many other organizations around the world.

“We are thrilled to introduce MagiCam, a game-changing tactical 3D mapping solution,” says Ronen Nadir, CEO & Founder at BlueBird. “This innovative system redefines the boundaries of large area mapping, delivering exceptional 3D products, accuracy, efficiency and capabilities never seen before. MagiCam’s integration with our WanderB-VTOL UAV further enhances its capabilities, providing customers with an unparalleled solution for their mapping needs.”

Blue Force Gear will be exhibiting at ADS Warrior Expo East on June 21–22 at the Virginia Beach Convention Center in Virginia Beach, Virginia. Reps will be on hand to talk about Blue Force Gear products. Stop by Booth #607 to meet the team and check out the latest from Blue Force Gear.

CAPE CANAVERAL SPACE FORCE STATION, Fla. – The 114th Space Control Squadron, a geographically separated unit assigned to the Florida Air National Guard’s 125th Fighter Wing, was redesignated as the 114th Electromagnetic Warfare Squadron Jan. 14.

The redesignation more accurately associates the unit’s name with its mission and aligns it with active-duty Space Force counterparts who were redesignated last year. It also reflects the evolution of electromagnetic warfare technologies to the forefront of space operations.

U.S. Air Force Lt. Col. Scott McGuire, commander of the 114th Electromagnetic Warfare Squadron, said the squadron will now be recognized, by name, as a combat unit providing critical electromagnetic warfare functions to joint force warfighters across domains. At the same time, they will continue providing the same support to the U.S. Space Force. This change also recognizes that these Airmen offer the same capabilities as their active-duty Space Force counterparts.

The 114th’s mission is to organize, train and equip personnel to conduct electromagnetic attacks in contested, congested and constrained environments downrange, using specialized equipment such as the counter communications system, or CCS. The CCS denies communications from satellites in orbit, cutting off adversarial communications during a conflict, creating a safer, more secure environment for U.S. and joint warfighters.

“Successful space operations depend on dominating the electromagnetic spectrum,” said Ed Zoiss, president of the space and airborne systems segment for L3Harris Technologies and a Navy veteran. “Denying our enemies the ability to use their space assets protects U.S. warfighter operations.”

While the mission is the same, the newly designated electromagnetic warfare squadron remains committed to developing combat-trained, combat-ready and combat-focused Airmen ready to support warfighters across all domains.

“The Department of Defense’s growing dependence on the electromagnetic spectrum to remain connected and share data is only growing,” said U.S. Air Force Lt. Col. Anthony Surman, assistant operations officer at the 114th Electromagnetic Warfare Squadron. “It’s important that we recognize that we need the capability to conduct both electromagnetic and kinetic attacks; we can deliver a multitude of options.”

Air National Guard units reporting to the former U.S. Space Command have continued supporting space-centric missions for the Space Force since its inception in 2019. The units have an atypical arrangement in which they fall under a major command of the Air Force while receiving operational taskings from the Space Force.

By Senior Airman Jacob Hancock, 125th Fighter Wing Public Affairs

On June 17, 2023, the MACH-TB program successfully launched its first suborbital testbed vehicle in a critical step forward toward advancing U.S. hypersonic technology.

To compete with U.S. adversaries, we must rapidly prototype and vet new technology at the speed of mission. The Multiservice Advanced Capability Test Bed (MACH-TB) project, is a dynamic initiative engineered to effectively evaluate and demonstrate hypersonic capabilities prior to integration into existing weapon systems.

“As the hypersonic race intensifies, there is an urgent need to quickly prototype and test this technology,” said S²MARTS Director Doug Crowe. “The MACH-TB launch announcement marks a pivotal stride forward in preserving America’s unrivaled technical dominance.”

The Naval Surface Warfare Center (NSWC) Crane division, leveraging the Strategic and Spectrum Missions Advanced Resilient Trusted Systems (S²MARTS) Other Transaction Authority (OTA), awarded the MACH-TB contract to Dynetics in September 2022. Supported by a formidable consortium of 12 subcontractors, the MACH-TB program is tasked with designing an experimental glide body that will undergo rigorous hypersonic capability tests to bolster various Department of Defense (DoD) initiatives.

The collective power of American innovators in the hypersonic race cannot be underestimated. Of the performers supporting MACH-TB, eight are non-traditional organizations who are new to defense, now standing shoulder-to-shoulder with established industry players. Through the S²MARTS OTA, the DoD successfully eliminated barriers to entry and expanded its reach to the nation’s premier commercial innovators, introducing groundbreaking technologies into the fold.

A collaborative partnership between national and DoD laboratories, academia, small businesses, non-traditional defense enterprises, and industry titans will foster the development and demonstration of hypersonic glide vehicle capabilities. These cutting-edge technologies will solidify America’s unassailable position in the realm of hypersonic technology.

The Rooftop Tent Shoe Bag from Intrepid Camp Gear is an ingenious answer to the issue of taking dirty footwear into a rooftop tent, or any shelter for that matter. It zips closed to protect your shoes from the elements (and critters).

The Hexå ferro rod fire starter from Überleben is offered in two sizes, 3″ and 6″. The hexagonal shape offers more contact surface during striking.

G-Shock has introduced the GBDH2000, their first watch with heart rate monitor. It also incorporates GPS to track your workout.

Casio describes the functions, “Using optical sensors to provide heart rate measurements, an accelerometer to count steps, and a gyroscope to improve swimming sessions, athletes can accurately monitor their training sessions.”

What’s more, it is rechargeable via USB or solar, the latter extending its use in the field.

Aside from the Black model with Red pop seen here but there is also a high viz Yellow band available as well as an Amazon exclusive murdered out version.