Tens of thousands of unsafe counterfeit pieces of apparel and gear were sold to the U.S. military to be issued to active duty airmen

PROVIDENCE – A Brooklyn, NY, clothing and goods wholesaler who directed the development, manufacture, and importation of $20 million worth of Chinese-made counterfeit U.S. military uniforms and gear that were passed off as genuine American-made products has been sentenced to forty months in federal prison and ordered to forfeit the $20 million in proceeds that he obtained from the sale of the counterfeit goods, announced United States Attorney Zachary A. Cunha.

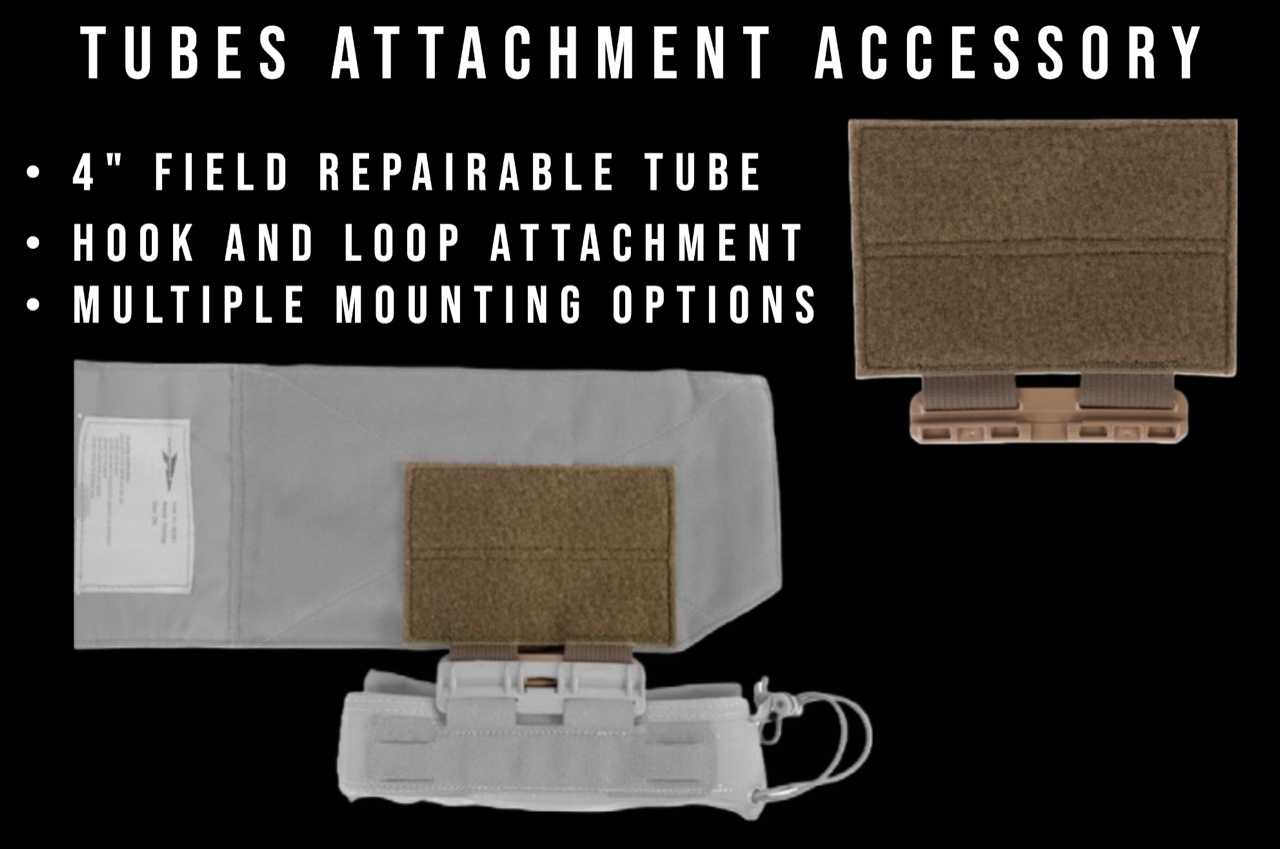

Ultimately, substandard, counterfeit goods manufactured in China were sold to the U.S. government to be worn or carried by Airmen in the U.S. Airforce. Some of these products lacked crucial safety features or failed to meet safety specifications, endangering the health and safety of the military personnel who wore them. At least 13,332 counterfeit jackets not resistant to enemies’ night vision goggles and 18,597 non-flame resistant hoods were among the counterfeit products that entered the military supply chain destined for U.S. Air Force bases around the world.

Ramin Kohanbash, 52, sentenced on Wednesday to forty months in federal prison, pleaded guilty in June 2019 to conspiracy to commit wire fraud and trafficking in counterfeit goods. Kohanbash will also be required to make restitution to the individual companies victimized by his conduct, including a Rhode Island company that reported a loss of more than $639,000 in profits and significant damage to its relationships with long-standing military clients due to the distribution of counterfeit products distributed by Kohanbash. The specifics of his restitution obligations will be determined at a later date.

“American servicemen and women risk their lives every day in defense of the nation,” said U.S. Attorney Cunha. “But the risks they face should never come from the uniforms they wear, and the equipment they carry. In this case, Defendants’ actions did exactly that, substituting substandard, foreign-made knockoffs for American products. I am tremendously pleased that the defendants charged in this matter are being held accountable for their actions.”

“The Defense Criminal Investigative Service (DCIS), the law enforcement arm of the Department of Defense (DoD) Office of Inspector General, is fully committed to protecting the integrity of the DoD supply chain,” said Patrick J. Hegarty, Special Agent in Charge of the DCIS Northeast Field Office. “Supplying counterfeit products to the DoD endangers the lives of American service members and betrays the public’s trust. This investigation and subsequent prosecution demonstrate DCIS’ ongoing commitment to working with its law enforcement partners to hold individuals who defraud the DoD accountable.”

A co-defendant in this matter, Bernard Klein, 41, of Brooklyn, was sentenced in April 2021 to eighteen months of incarceration to be followed by three years of federal supervised release; ordered to pay a fine of $15,000; and to pay restitution in the amount of $400,000. In tandem with the criminal case, Klein also entered into a civil settlement agreement under which he has paid $348,000 to resolve liability to the United States under the federal False Claims Act for goods sold to certain government purchasers.

A third defendant, Terry Roe, 49, of Burlington, North Dakota, is scheduled to be sentenced on October 20, 2022. He pleaded guilty in February 2022 to conspiracy to commit wire fraud and traffic in counterfeit goods.

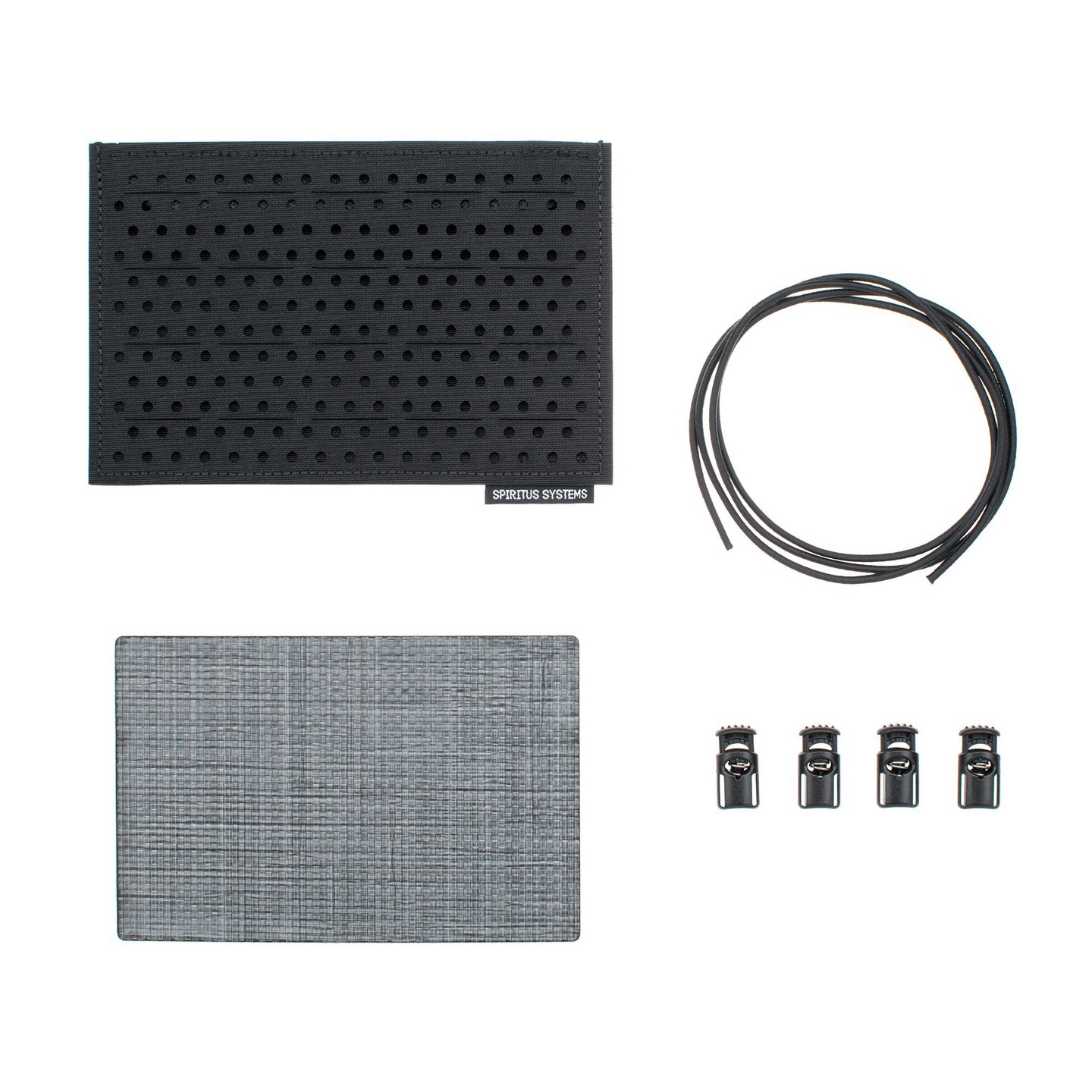

According to information provided to the court, Kohanbash worked collaboratively with Roe and Klein to provide samples of actual military uniforms and gear to manufacturers in China, including sample tags and labels that depicted trademarks of fifteen companies who make products for the military in the United States. The Chinese manufacturers then counterfeited the products, tags, and trademarks. The counterfeit products were shipped to Kohanbash’s New Jersey warehouse and sold to the United States military and its suppliers, including a North Dakota supplier where Roe was employed.

According to court filings, Kohanbash and Klein strategized on how to subvert Chinese and American customs to ensure that the counterfeit military uniforms and gear were successfully imported from China into the United States and received at Kohanbash’s New Jersey warehouse. The bogus goods were then sold to the United States military and its suppliers. Additionally, Kohanbash and Roe deceived personnel at military Base Supply Centers by including false certification letters claiming that the goods were manufactured in the United States. U.S. laws require that products sold to the U.S. military and certain other government buyers be manufactured in the United States or certain other designated countries; China is not one of those countries.

The Kohanbash, Klein, and Roe prosecutions are part of a group of parallel criminal and civil enforcement actions undertaken by the United States Attorney’s Office to bring to justice individuals and companies involved in the production, marketing, and sale of counterfeit goods to military and government purchasers.

As part of this effort, the United States has also reached three separate settlements under the federal False Claims Act in connection with this conduct. These civil settlements, with Klein, Kohanbash, and the Dakota Outerwear Company of Minot, ND, have recovered a total of $2,042,398 for these defendants’ roles in a scheme to procure and sell counterfeit, and in some cases, defective and nonconforming goods, to federal purchasers.

The cases were prosecuted by Assistant U.S. Attorneys Sandra R. Hebert, Richard B. Myrus, and Lee H. Vilker.

The matter was investigated by the U.S. Defense Criminal Investigative Service, Northeast Field Office; General Services Administration Office of Inspector General, New England Regional Investigations Office; Army Criminal Investigation Division, Major Procurement Fraud Field Office; the U.S. Air Force Office of Special Investigations, Office of Procurement Fraud Detachment 6, Joint Base Andrews, MD; Homeland Security Investigations, Newark, NJ; and Customs and Border Protection, New York Field Office.