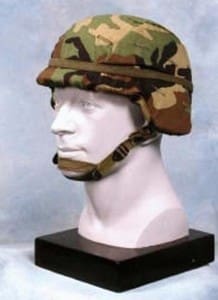

Some readers are undoubtedly familiar with the PASGT helmet of old. The “Dome of Obedience”, “K-Pot”, “Clay Beret”, “Brain Wave Deflector” or any other number of unflattering names might come to mind depending on when and where you had to wear one. It was hot in the summer, cold in the winter, didn’t sit still on your head leaving blisters, or if it did sit still you were getting a migraine. There was nothing good about the K-Pot that I can remember now. Maybe it’s because it’s been over a decade since I wore one, and I’m spoiled by newer, better helmets. Maybe it’s because that helmet truly sucked. Fortunately, we’ll never have to put much thought into it, because helmet design and technology has come so far that most professional users don’t have to dread the call to put their helmets on any longer.

Some readers are undoubtedly familiar with the PASGT helmet of old. The “Dome of Obedience”, “K-Pot”, “Clay Beret”, “Brain Wave Deflector” or any other number of unflattering names might come to mind depending on when and where you had to wear one. It was hot in the summer, cold in the winter, didn’t sit still on your head leaving blisters, or if it did sit still you were getting a migraine. There was nothing good about the K-Pot that I can remember now. Maybe it’s because it’s been over a decade since I wore one, and I’m spoiled by newer, better helmets. Maybe it’s because that helmet truly sucked. Fortunately, we’ll never have to put much thought into it, because helmet design and technology has come so far that most professional users don’t have to dread the call to put their helmets on any longer.

Around 2000, SOF Special Projects at Natick Labs developed the MICH (Modular Integrated Communications Helmet) as a replacement for the PASGT and other helmets in use by Special Operations units. It was of a French design (Gallet) and after being purchased by MSA, Berry compliant production began in the US in 2001 in a factory in VT, forever changing the way users looked at wearing a ballistic helmet. The MICH was a huge improvement over the PASGT, so much better in fact I have a hard time putting it into words because there’s not a metric to describe it. The MICH allowed users to finally stabilize night vision systems efficiently and conduct free-fall operations with its improved harness, remain comfortable and control perspiration with its 7-piece user configurable pad set, as well as fire from the prone and use integrated communications headsets (such as the Peltor or Sordin products) because of its interior and exterior profile.

Around 2000, SOF Special Projects at Natick Labs developed the MICH (Modular Integrated Communications Helmet) as a replacement for the PASGT and other helmets in use by Special Operations units. It was of a French design (Gallet) and after being purchased by MSA, Berry compliant production began in the US in 2001 in a factory in VT, forever changing the way users looked at wearing a ballistic helmet. The MICH was a huge improvement over the PASGT, so much better in fact I have a hard time putting it into words because there’s not a metric to describe it. The MICH allowed users to finally stabilize night vision systems efficiently and conduct free-fall operations with its improved harness, remain comfortable and control perspiration with its 7-piece user configurable pad set, as well as fire from the prone and use integrated communications headsets (such as the Peltor or Sordin products) because of its interior and exterior profile.  It’s around half a pound lighter than the PASGT. In addition, Soldier survivability was greatly increased due to a combination of the shell performance and the suspension system. The MICH allowed much less energy to be transferred to the wearer’s head in the event of a serious collision, be it with a bullet or a blunt impact from a fall or debris. Shortly after SOF adopted the MICH, it was adopted by the entire US Army as the ACH (Advanced Combat Helmet) program and still in use today. Safe to say, the MICH was an overwhelming success. Based on user driven requirements, the MICH design was further modified into the popular TC-2001 High Cut and TC-2002 Gunfighter Cut designs from MSA which are still widely in use around the world as well.

It’s around half a pound lighter than the PASGT. In addition, Soldier survivability was greatly increased due to a combination of the shell performance and the suspension system. The MICH allowed much less energy to be transferred to the wearer’s head in the event of a serious collision, be it with a bullet or a blunt impact from a fall or debris. Shortly after SOF adopted the MICH, it was adopted by the entire US Army as the ACH (Advanced Combat Helmet) program and still in use today. Safe to say, the MICH was an overwhelming success. Based on user driven requirements, the MICH design was further modified into the popular TC-2001 High Cut and TC-2002 Gunfighter Cut designs from MSA which are still widely in use around the world as well.

12 years after the arrival of the MICH/ACH and its variants, a few newer designs have gained a lot of attention. The Crye Precision AirFrame and Ops-Core FAST are the two we see primarily, both gaining lots of popularity in Special Operations and Law Enforcement communities. USSOCOM has begun fielding of the FAST helmet and can regularly be seen in media released by USASOC on the heads of Rangers and Special Forces Soldiers. Crye’s design is also in limited military use. Of note, Crye and Ops-Core seem to be the other’s stiffest competition but cooperate on numerous parts of their helmet systems. Both helmets are commonly seen shipped from the factory with Ops-Core’s excellent Head-Loc strap system, VAS Shroud, and ARC rails. In fact, the Ops-Core chinstrap system is the standard for the SOCOM issue MICH. Additionally, both helmets can be ‘up armored’ with additional armor pieces to increase the helmet’s ballistic coverage.

The FAST helmet uses Ops-Core’s OCC Dial technology, which is also available as a retrofit kit for MICH style helmets. The system uses a headband that is tightened to the wearer’s head with a dial on the rear for custom fit, in addition to dual-density foam pads on top of the head. The system is extremely stable with night vision systems, especially heavier dual tube I2 goggles or Fusion systems. Ops-Core also boasts a 20% reduction in weight over traditional helmet materials due to their carbon/polyethylene blend shell composition. The helmet has strategically placed loop tape panels for IFF marking and battery pack placement, and usually is seen with Ops-Core’s popular VAS Shroud for NVG integration. They also include the proprietary ARC Rail for attachment of lights, goggles, MFF 02 masks and communications systems. Excellent covers in a variety of colors and camouflage patterns are available through FirstSpear, and should be a must-have for any end-user, reducing the slight shine found on uncovered helmets and offering increased camouflage in a wider variety of environments. In addition to widespread fielding by US SOF, the FAST is the issued helmet for the entire Norwegian Army. Something that may appeal to buyers is the availability of non-ballistic FAST (Bump) helmets as well, replacing cobbled together skateboard helmets with a purpose designed impact protection helmet.

Crye’s AirFrame uses a similar carbon-backed shell technology, a special version of the Ops-Core ARC rail system designed specifically for the AirFrame and Head-Loc chinstrap. Depending on the user, it may be fitted with an Ops-Core VAS Shroud or a Wilcox mount. Crye opted to use the MICH style pad set as opposed to a dial system of some sort, but the big thing you’ll notice about the Airframe is it’s unique shell shape…most prominently the huge vent in the top. The rear half of the two-piece shell rests under the front piece with some overlap, creating a rear-facing vent in the top of the helmet. The vent allows heat and moisture to escape out the top of the helmet, and also allows the rear on the helmet to fit closer to the wearer’s head for improved mobility, protection and fit. Crye offers a mesh helmet cover that is custom fit for the Airframe, maintaining its unique passive cooling properties. The Crye AirFrame can be ordered full assembled with NVG mounts in various hole patterns, ARC rails, and a cover, or stripped with only the shell and suspension system. One word of advice, make sure you can try one on. Some people have found they need a size larger in the AirFrame.

Onwards to the subjective stuff. I wore a MICH for a long time, and I’m lucky enough to have an AirFrame now. If I had to wear my MICH again I would gladly do it but the AirFrame is a huge improvement in comfort for me. What’s a fact is the tremendous weight savings over a helmet of the same capability a few years ago. The reduction in fatigue and potential injury due to the AirFrame’s greatly decreased weight is worth the price of admission. Check it out:

State of the Art, 2008

MSA TC2000 helmet, medium

Ops-Core H-Nape

Ops-Core ARC rail

ITT ANVIS mount and low-pro battery pack with ground adapter plate

Norotos NVG plate

Oakley A-Frame assault goggles

MS2000 strobe

Peltor Comtac I

Crye Precision 1000D helmet cover

Total Weight: 6lb 4.6oz

State of the Art Today

Crye AirFrame, size Large

Ops-Core H-Nape

Ops Core Airframe ARC rail

Ops-Core VAS Shroud

Wilcox FO4949 mount

Smith Elite Boogie goggle

S&S V-Lite

Peltor Comtac IV in ARC adapter kit

Crye Airframe mesh cover

Total Weight: 4lb 2.0oz

The numbers don’t lie. Removing 2lb 2.6oz off of the wearer’s neck during extended combat operations, while improving fit, function, and protection is a huge gain. Both helmets above share the exact same capabilities, it’s just that one does it 68% of the weight of the other while offering better protection. While the raw weights are closer of the two helmets alone, the improvements on the things we mount on them have also played a huge part in load reduction as well and should be factored in. If you still use a MICH/ACH you can save weight and improve function by upgrading mounting systems, eye protection, and IFF marking products.

If you’re due up for an upgrade on your ballistic head protection, take a look at Crye or Ops-Core. At least find ways to make you current setup lighter and more functional, as the head is one of the best places to try and reduce your load.

www.cryeprecision.com

www.ops-core.com

Jon Canipe served on Active Duty with the US Army as a Special Forces Weapons Sergeant at 5th SFG(A) and was a Senior Instructor at the JFKSWCS, training SFQC students in planning, unconventional warfare, small unit tactics, CQB, and advanced marksmanship. He is a veteran of multiple combat tours, and still serves in the Army National Guard’s 20th SFG(A) in addition to working as an industry consultant and small arms instructor.