W.L. Gore & Associates has announced it will be featuring its expanded line of FR military apparel, consisting of several jackets. The Improved EWOL now features Pyrad face fabric rather than the Nomex fabric on the current model. I have long been a fan of Gore’s Pyrad technology which retains the performance of the base fabric yet adds FR capability.

The full release can be read below:

ELKTON, MD, OCTOBER 13, 2014 – – W. L. Gore & Associates, Inc., will be featuring its expanded line of flame-retardant (FR) military apparel at the 2014 AUSA Exposition in Washington, D.C., October 13-15, in Booth 2719. The portfolio includes: Gore’s FR Lightweight Loft (LWL) Jacket; GORE® PYRAD® Hardshell Jacket; EWOL (Extreme Weather Outer Layer) Jacket; and an IWOL (Intermediate Weather Outer Layer) Jacket. All products meet or exceed industry standards for flammability and thermal protective performance. Standards include, where applicable: PYROMAN™ – ASTM F 1930; Thermal Protective Performance (TPP) – ISO 17492; Flammability – Folded Edge Flame Test Method – ASTM F 1358; and Vertical Flame Test Method – ASTM D 6413.

The GORE® PYRAD® Hardshell Jacket incorporates a self-extinguishing fabric technology that offers protection in heat and flash-fire incidents. The fabric increases thermal protective performance and reduces potential for burn injury. It provides increased thermal stability and maintains physical integrity in the event of exposure to heat and flames. Further, the jacket is waterproof/windproof/breathable due to its GORE-TEX® fabric construction, making it not only protective but comfortable to the wearer in extreme environments, as well.

Gore’s FR Lightweight Loft (LWL) Jacket, which features GORE® PYRAD® Flame Retardant, provides proven heat and flame protection against battlefield hazards without sacrificing protection from the elements, especially cold temps. Gore’s FR Lightweight Loft Jacket provides heat and flame protection, is highly breathable, dries fast and packs quickly.

Gore’s next generation Extreme Weather Outer Layer (EWOL) jacket provides weather protection utilizing a waterproof, windproof, and breathable GORE-TEX® membrane combined with GORE® PYRAD® Flame Retardant. It is comfortable, provides antistatic protection, and offers penetration resistance against JP-8, DEET, petroleum, oils, and lubricants.

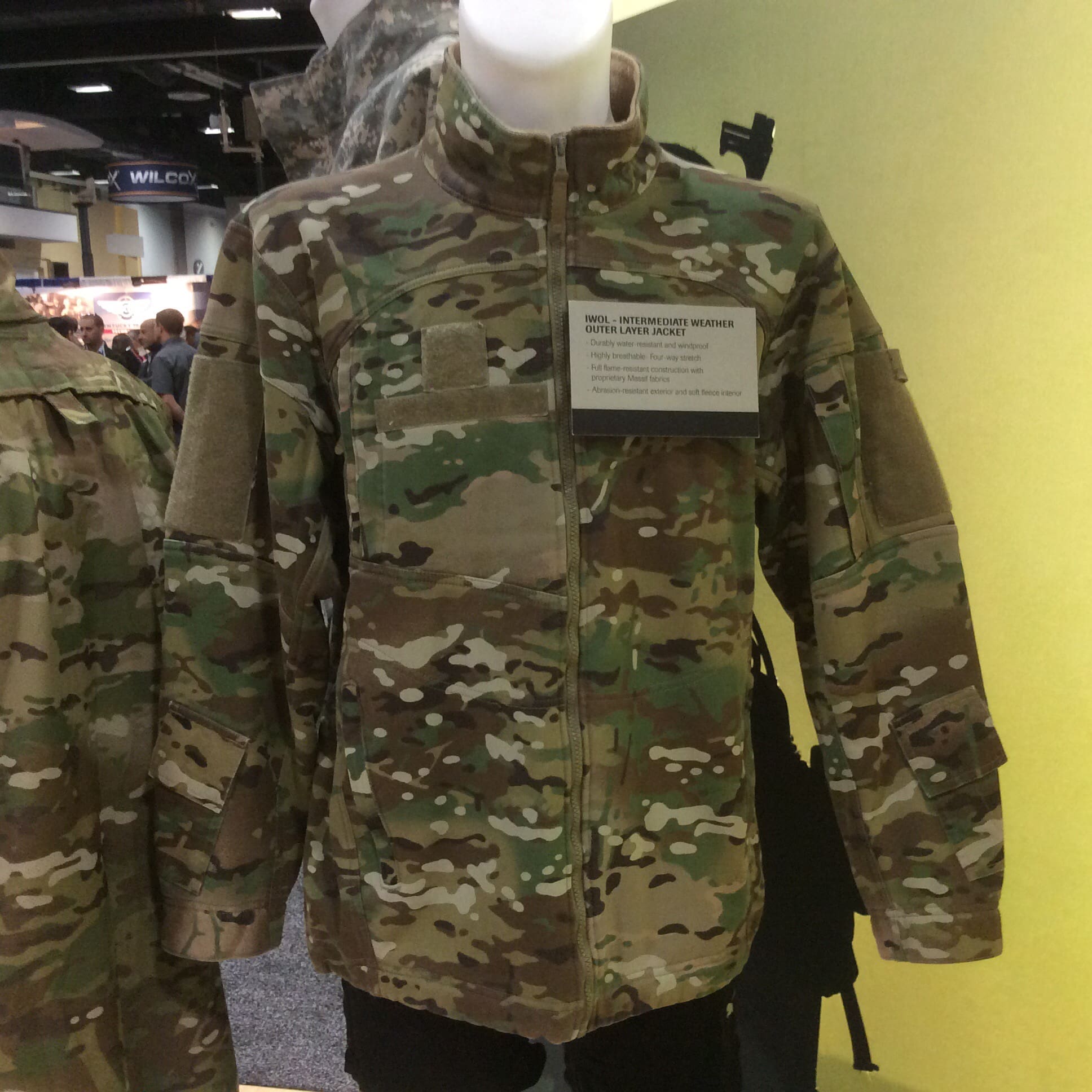

The Intermediate Weather Outer Layer (IWOL) jacket is constructed from a MASSIF® fabric featuring GORE® FR Stretch technology in a revolutionary nylon-faced, flame resistant, water resistant laminate. This extremely durable, highly breathable fabric offers a superior warmth-to-weight ratio. GORE® membrane technology provides weather protection from rain and wind. The result is a high quality, comfortable, softshell jacket with heat and flame protection.

GORE® PYRAD® Flame Retardant is an advanced laminate technology that offers an optimal combination of thermal / flashover burn protection, environmental protection, and comfort. This unique technology self-extinguishes flames so that the fabric does not continue to burn. Traditional non-FR textiles will continue to propagate flame, exhibit melting and dripping, and increase the potential of burn injury to the skin. GORE® PYRAD® Flame Retardant increases thermal protective performance and reduces potential for burn injury.

For more information on Gore’s line of FR garments, visit Gore at the 2014 AUSA Exposition in Washington, D.C., October 13-15, in Booth 2719.