JOINT BASE ELMENDORF-RICHARDSON, Alaska — Team members with the U.S. Army Medical Materiel Development Activity joined a multinational military and government contingent to test developing medical technologies and treatments at Joint Base Elmendorf-Richardson, March 4-6, 2024.

As part of the U.S. Northern Command’s Arctic Edge 24 exercise, USAMMDA developers partnered with frontline military medical providers to conduct below zero medicine exercises and experiments and assess the progress of the U.S. Army’s freeze-dried plasma and extreme cold weather shelter programs.

Arctic Edge 24 is a premier venue to demonstrate how USAMMDA’s programs fit into the Army and Department of Defense’s future operating concepts, including a focus on the Arctic regions of the globe, according to U.S. Army Col. Andy Nuce, commander of USAMMDA.

“Exercises like Arctic Edge 24 are a great touchpoint for USAMMDA’s development teams because they give us a chance to interface with potential end users of devices and treatments during the development process,” said Nuce, who has helmed the activity since June 2022. “This is important for two reasons. One, it gives our teams a chance to see devices in real-world environments that we cannot fully replicate at Fort Detrick. Two, the Soldiers who are using the devices during these types of training give us incredible insight into where products are in development within the acquisition pipeline, and how we can improve the process going forward to deliver the best possible products for eventual fielding.

“In short, the Soldiers in the field are critical to our understanding of what is needed and how we can improve the development process going forward to meet their future needs in order to save lives.”

Exercises like Arctic Edge 24 align with the wider Army preparedness doctrines outlined in the forthcoming Army publication “Arctic and Extreme Cold Weather Operations” and showcase how Army medical development commands are refining their focus to meet the challenges of Arctic warfighting, including medical readiness.

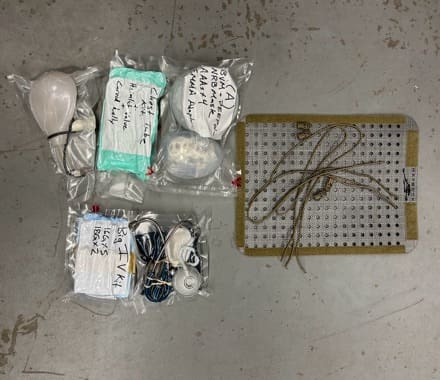

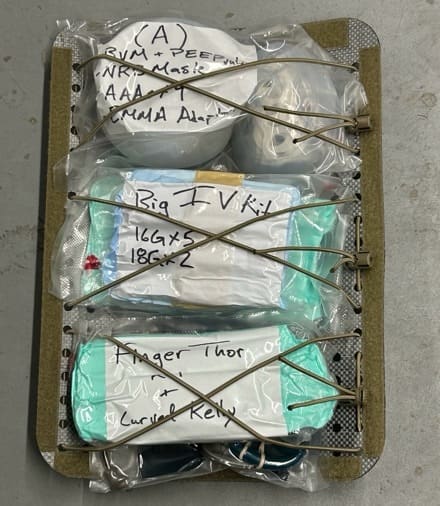

The first of two USAMMDA teams attending the exercise, the freeze-dried plasma — known as FDP — developers, are working with combat medics and medical officers to continue the years-long adaptation of blood plasma in freeze-dried form for far-forward use. The lightweight and expeditionary FDP under development by USAMMDA’s Warfighter Protection and Acute Care Project Management Office is a critical advancement in blood replacement capabilities for frontline troops, according to Michelle Mason, a logistics specialist with the WPAC PMO who attended the exercise.

“The FDP program is a significant step forward to equip military medical personnel to provide urgent care at and near the front lines,” said Mason. “When Warfighters are injured, every moment is critical to improving their chances of survival.”

Blood plasma is a lifesaving tool that helps boost a patient’s blood volume to help prevent shock and aid with blood clotting, according to the American Red Cross. WPAC is developing both human and canine FDP to give future military medical providers another option when treating critically injured servicemembers and military working dogs.

For the past several years, the U.S. Army has been focusing on modernizing its forces to meet the challenges of 2030, 2040 and beyond. A main component of this wider strategy is improving lifesaving care for wounded and injured Warfighters at and near the front lines. The U.S. Department of Defense’s focus on dispersed operations, with logistics lines crossing thousands of miles of open ocean and barren tundra, makes building frontline care capacities imperative to joint force readiness, according to Mason.

“During previous conflicts, like in Iraq and Afghanistan, U.S. forces had unparalleled abilities to treat and evacuate the wounded to higher echelons of care, due to wide accessibility of medevac aircraft and relative proximity of secured bases with advanced medical treatment facilities and devices,” said Mason. “Those advances greatly improved survivability compared to previous U.S. wars. Today’s warfighters are preparing to fight in areas of the world that are much more austere and rugged, where the ‘front line’ will be geographically isolated, dispersed and harder to reach by air and seacraft to evacuate the critically wounded.

“This is why developing treatments like FDP is so important to the DoD’s modernization efforts,” she added. “The advantages of longer shelf life, reduced logistical burden, safety and efficacy that are built into these types of materiel solutions will be vital during future conflicts to enable medical personnel to sustain life until medevac transportation can be arranged to higher levels of care.”

The second USAMMDA contingent participating in Arctic Edge 24 works with commercial partners to assess the development of rugged, extreme cold weather treatment shelters for use in Arctic environments. When a servicemember is wounded or injured, a complex series of actions begins. Frontline medical personnel initially work to stabilize the patient by keeping airways open, applying pressure to limit blood loss and treating for shock. Next, triage priorities determine the order for movement to higher echelons of care, with the most severely wounded or injured given highest priority.

During dispersed operations in extreme climates, when medevac transportation could be limited, the need to shelter casualties in a safe, dry, and warm environment while waiting for further care is imperative to ensure the patient remains stable. The Warfighter Readiness, Performance, and Brain Health PMO team attended Arctic Edge 24 to assess the worthiness of their shelter program in the most extreme climate imaginable, according to Emily Krohn, an assistant product manager with the team.

“Extreme cold weather is a different sort of enemy to our Warfighters when they are injured or wounded,” said Krohn, who attends a dozen Army and joint force exercises each year in her role as a product manager. “The climate can be a huge challenge during combat operations because it not only limits evacuation options, but it can compound and worsen the effects of serious wounds and injuries.”

USAMMDA relies on many partners to accomplish its mission, according to Krohn. Its development experts work with others across the Army, special forces community and medical industry to conceive, research, develop and test the technologies and treatments that future Warfighters will rely on to fight and win. Exercises like Arctic Edge 24 are a perfect platform to measure the effectiveness of USAMMDA’s development programs, including extreme cold weather shelters that are rugged, expeditionary and designed to meet the needs of warfighters during future conflicts.

“The shelters we are developing with the U.S. Army Combat Capabilities Development Command Soldier Center and our commercial partners are designed to enable frontline medics to safely evacuate casualties and provide tactical combat casualty care in a temperature-controlled environment while arranging for movement to higher echelons of care,” said Krohn. “These types of technologies are being developed to answer the challenges servicemembers and frontline providers may face in extreme cold weather.”

By T. T. Parish