*Soldier Systems Daily Exclusive*

We received an excerpt of the 2009 Natick report “PHOTOSIMULATION CAMOUFLAGE DETECTION TEST” in order to determine the origin of the so-called “Syrian” pattern.

The internet has been aflame with concern and indignation that a “Syrian” camouflage pattern is out performing UCP. Still others have taken recent articles printed on other websites as an indication that the Army is considering this pattern for issue but nothing could be further from the truth.

In an effort of clearing the air, Soldier Systems Daily offers these quotes taken directly from the report followed by some analysis. A couple of tidbits from the report:

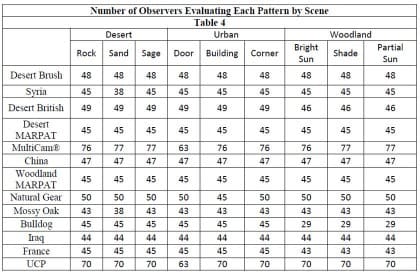

“Eighteen patterns were included in the imagery collection and observer data collection.

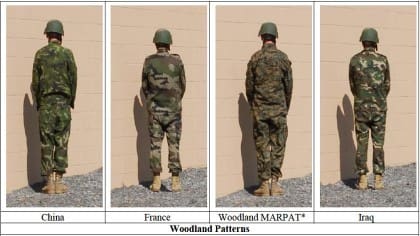

Guidance for pattern selection was given by BG Brown, PEO-Soldier in March 2007. Guidance included patterns of foreign countries, patterns presently available on the commercial market and the UCP. Final pattern selection was controlled by pattern availability. The Woodland and Desert Battle Dress Uniforms (BDU) were not included in this evaluation because, at the time of pattern selection, they were not being worn by the U.S. Army.

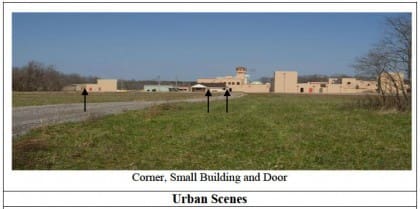

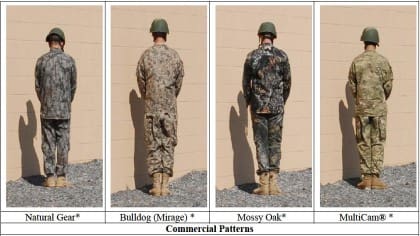

All targets wore desert combat boots and a green Advanced Combat Helmet (ACH). Helmet covers were not worn because of the lack of availability of covers for most patterns. Deployment and training schedules limited the availability of observers during the short data collection period. Therefore, to focus data collection on the patterns of greatest interest, the patterns were prioritized into two tiers. When a complete data set was collected on the Tier 1 patterns, which are annotated in Figures 6-10 with an asterisk, observer data collection then began on the Tier 2 patterns.

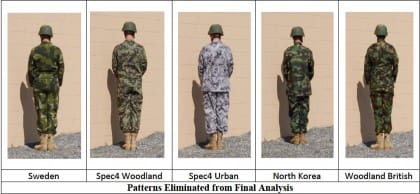

Although detection data were collected on 18 patterns, five patterns (i.e., Sweden, Spec4 Woodland, Spec4 Urban, North Korea, and Woodland British) were eliminated from the final data analysis. The two Spec4 patterns were not available for desert image collection; therefore, they did not have a complete data set. Sweden, North Korea and Woodland British were eliminated, due to being the worst performers in two out of the three environments. Their similarity to other woodland patterns was further justification, although it must be noted that detection data are available for further analysis, if desired.”

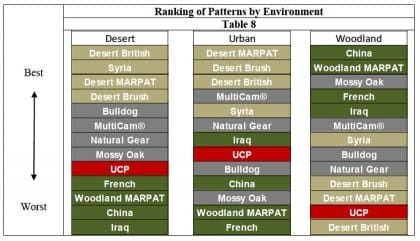

“Given these environment-specific results, five patterns consistently performed better than UCP – Syria, Desert MARPAT, Desert Brush, MultiCam®, and Natural Gear.

Although the performance of the Natural Gear pattern was consistently better than UCP, it is not a viable pattern to consider for possible near-term military use because it does not have military near-infrared properties and the Government has no rights to the pattern. Natural Gear was also the lowest performer of this group of five patterns. Therefore, further discussion is focused on the remaining four uniforms – Desert MARPAT, Desert Brush, MultiCam® and Syria. Syria, although a foreign uniform and not practical for U.S. military use, yielded very favorable results in the environments tested and may be useful in future research on pattern / color effectiveness in multiple environments.“

italics added for emphasis (mine)

As you can see from the study, the now infamous “Syrian” pattern is not under consideration for issue to US troops but rather considered a “lab pet” to be used during future camouflage study.

This is the photograph of the “Syrian” camo from the Natick report. Unfortunately, we still do not know the true origin of this pattern. International camouflage experts have reviewed that photo and determined that it is not on general issue to Syrian forces. Furthermore, it has been suggested that it closely resembles the German Sumpfmuster (Marsh Pattern) issued to the Bundes Grenz Schutz from the late 50s on. This pattern in particular was based on a WW II German Army Marsh pattern and has been also worn by the Libyan military.

Notice that “British Woodland”, beloved Temperate DPM was eliminated due to being among the worst performers in the study but on the flip side, Desert DPM fared pretty well. Interestingly, this will be very big news across the pond as the British military struggles with PECOC and their efforts to field a more effective pattern for operations in the Middle East.