The U.S. Army Contracting Command – New Jersey (ACC-NJ), on behalf of Project Manager Soldier Weapons, is seeking proposals in regards to a Prototype Opportunity Notice (PON) for Next Generation Squad Automatic Rifle (NGSAR). The NGSAR is the first variant of the Next Generation Squad Weapons. The NGSAR will address operational needs identified in various capability based assessments and numerous after action reports. The NGSAR is the planned replacement for the M249 Squad Automatic Weapon (SAW) in Brigade Combat Teams (BCT). It will combine the firepower and range of a machine gun with the precision and ergonomics of a rifle, yielding capability improvements in accuracy, range, and lethality. The weapon will be lightweight and fire lightweight ammunition, improving Soldier mobility, survivability, and firing accuracy. Soldiers will employ the NGSAR against close and extended range targets in all terrains and conditions. The NGSAR support concept will be consistent and comparable to the M249 SAW involving the Army two-level field and sustainment maintenance system.

Significance

NSGAR promises to be the most significant change to small arms technology since the 1960s. In one program, they hope to replace both the M4 carbine and M249 SAW. Hopefully, this won’t prove to be another Individual Carbine program where industry spends millions of Dollars and offers significant improvement, but institutional momentum gets in the way of progress. Fortunately, the Chief of Staff of the Army supports this initiative, but the program schedule will take it out long past his tenure. Hopefully, it will remain an Army priority.

Acquisition Methodology

The US government is trying to speed up the way it procures material for the Department of Defense. This program’s means of acquisition is a lot more like how the military procured the Joint Light Tactical Vehicle than how they purchased Modular Handgun System.

The Army’s schedule for NSGAR is also very aggressive. Lots of time and money has been spent on the Lightweight Small Arms Technology development effort which has been used to inform this effort. It’s gotten them this far, but the fact that they are moving forward with NSGAR tells me that at least someone realizes it’s still not yet ready for prime time. That means we are going to see a lot of new ideas with NSGAR.

Deliverables

The purpose of this PON is to award up to five Prototype OTAs with the goal of developing, within 12 months, a system demonstrator representative to include a functional prototype weapon, 2,000 rounds ammunition(s), fire control (day and night), bipod, suppressor, enablers (optional), spare part(s) to support firing 2,000 rounds, special tools, and operator manuals capable of firing and demonstrating the proposed capabilities to meet the lethality requirements. The goal is to develop system demonstrator representative of a Technology Readiness Level (TRL) 6 and Manufacturing Readiness Level (MRL) 6.

A system Demonstrator refers to a functional prototype weapon, 2,000 rounds ammunition(s), fire control (day and night), bipod, suppressor, enablers (optional), spare part(s) to support firing 2,000 rounds, special tools, and operator manuals capable of firing and demonstrating the proposed capabilities to meet the lethality requirements.

Follow-On

Following these efforts, a full and open competitive PON for a follow-on system integration prototype project may be announced. Participation in this system demonstrator PON is not required for participation in the follow-on system integration prototype project.

This Future Follow-On System Integration Prototype Project may be initiated with a new competitive PON requiring a system demonstrator (minimum TRL 6, MRL 6) bid sample and proposal. The combined evaluation of bid sample test results and proposal may result in the award of up to three independent OTAs. The OTAs may include decision points (e.g. Critical Design Review (CDR), Test Readiness Review (TRR), Product Qualification Test (PQT), and other critical tests) to continue or discontinue the OTA throughout the acquisition cycle. The system integration prototype project may include a full system integration, ensure a producible product that is safe, interoperable, affordable and sustainable through modeling, simulation, user evaluation and testing with a goal of delivering production representative systems achieving a TRL 8 and MRL 8. OTA deliverables may include 350+ weapons with fire control and other enablers, over 1,500,000 rounds of ammunition, spares, special tools, and manuals. Successful completion of the system integration prototype project may qualify Awardees for continuation into a follow-on production and deployment (P&D) effort without further competition.

Although the government states that a vendor need not participate in this go around to bid on the next, past experience has shown that participants in the initial effort glean a great deal of feedback, giving them an obvious advantage.

After that, the government may pursue a Future Follow-On P&D Effort(s), awarding up to two independent follow-on production OTAs or up to two independent Federal Acquisition Regulation (FAR) based contracts with a period of performance up to ten years. The P&D effort may include low rate initial production, operational test and evaluation, full rate production, fielding, and sustainment capability. Deliverables may include over 15,000 weapons with fire control and other enablers, over 30,000,000 rounds of ammunition with planned transition to Government run production (pending intellectual property if required), spares, special tool, manuals, and depot support.

Industry Challenges

Teams must be formed which include Weapon, Ammunition, and Electronics manufacturers. Due to the fast pace of this program, if they aren’t already working together on a strategy, both they and the government will miss out. Additionally, as I’ve critiqued in the past, the insistence on classifying program data has served as a bar to entry for many potential solution providers who cannot access program data.

To participate, offerors must meet at least one of the following conditions:

(A) There is at least one nontraditional defense contractor or nonprofit research institution participating to a significant extent in the prototype project.

(B) All significant participants in the transaction other than the Federal Government are small businesses or nontraditional defense contractors.

(C) At least one third of the total cost of the prototype project is to be paid out of funds provided by sources other than other than the Federal Government.

That means, all of the large, traditional defense contractors who were anticipate will be paying quite a bit out-of-pocket to participate.

Weapon

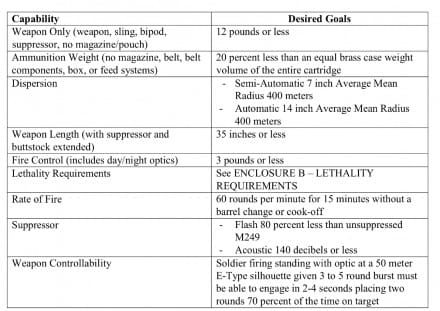

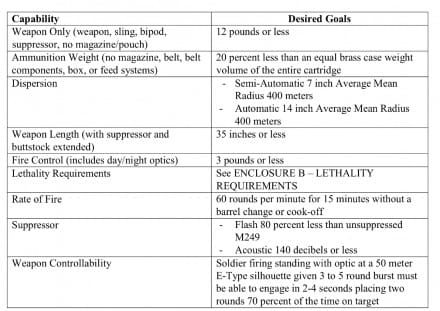

NSGAR prototype candidates should be 35” overall length including a suppressor which must offer 140 dB performance. NSGAR will feature Safe, Semi-Automatic and Automatic modes, with 400m dispersion.

Although the desired rate of fire is 60 rpm, this initial go around is to define trade space. That rate of fire is going to be a challenge with a box fed weapon, although rumor has it the government prefers a magazine over beltfed.

Ammunition

The ammunition must be “20% less than an equal brass case weight volume of the entire cartridge.”

Fire Control

Fire control is a critical component of this program. It’s inclusion alone will keep many firearms manufacturers from participating due to the costs and unique technical expertise required to produce these components. Likewise, Electronics manufacturers will lack the know how to produce firearms.

The system demonstrator is encouraged to include additional capabilities such as: advanced fire control (direct view optic with variable magnification, laser range finder, ballistic calculator, environmental data, disturbed reticle, etc.), powered/intelligent rail (including data transfer), ammunition capacity (belt or box fed), and other enablers which enhance military utility.

Submissions

Offerors have until April 9th to make their submission. PON proposals will be evaluated on Concept, Feasibility and Price with all three

having equal weight.

Read all of the details here.

www.fbo.gov

Some of this information is derived from the NSGAR Industry Comments.