See Litefighter’s new display in booth number 8262. They would like to extend an invite for everyone to stop by for a visit.

See Litefighter’s new display in booth number 8262. They would like to extend an invite for everyone to stop by for a visit.

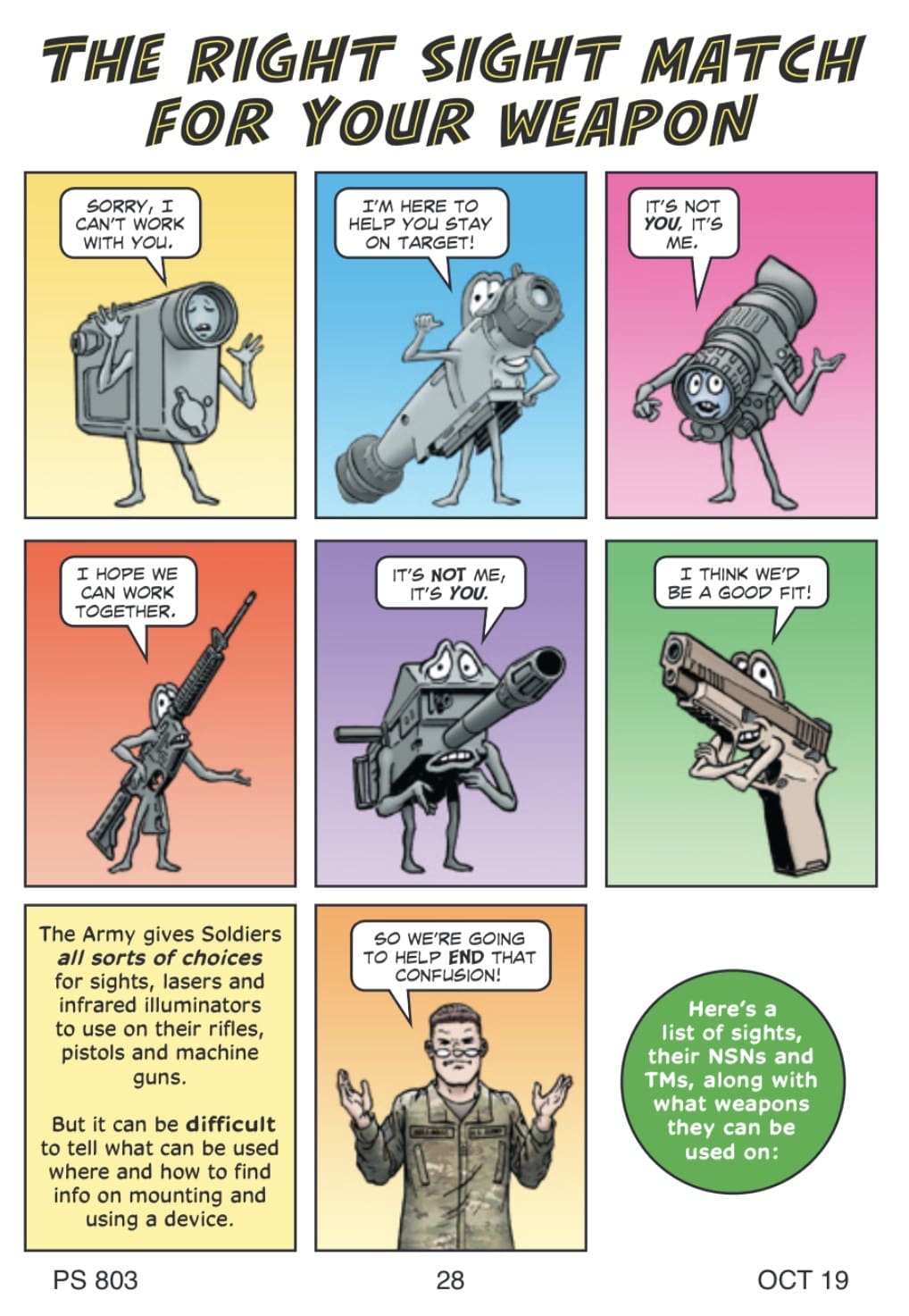

The Army gives Soldiers all sorts of choices for sights, lasers and infrared illuminators for their rifles, pistols and machine guns. But it can be confusing trying to sort out which sight is right for which weapon. This issue of PS Magazine focuses on on the problem.

Read PS online: www.aschq.army.mil/home/psmag

Get the new Mobile App to read PS on your phone or tablet, see maintenance videos and catch the latest maintenance updates.

Download free from the app stores:

Point Blank is exhibiting several new products at this year’s AUSA.

Carbondale, PA, October 11, 2019. Gentex Corporation, a global leader in personal protection and situational awareness solutions for defense forces, emergency responders, and industrial personnel announced today that its new Ops-Core® FAST SF Carbon Composite Helmet System has been chosen by the U.S. Special Operations Command (USSOCOM) to fulfill their contract for Special Operations Forces Personal Equipment Advanced Requirements (SPEAR) Family of Tactical Headborne Systems (FTHS) — Coxswain Helmet System. The five-year Indefinite Delivery Indefinite Quantity (IDIQ) Firm Fixed Price (FFP) production contract carries a maximum value of $95M.

Gentex Corporation has been supplying products to USSOCOM since its activation in 1987 and is focused on designing and delivering solutions driven by end user input. Just recently, the company was awarded contracts for the USSOCOM SPEAR FTHS Ballistic and Non-Ballistic Helmets, as well as the USSOCOM Communication Accessory Suite Land (CASL) program for it’s Ops-Core Adaptive Mission Platform (AMP™) Communication Headset.

“We’re extremely pleased to have been chosen to provide the Coxswain Helmet System for USSOCOM,” said Tom Short, vice president of Ground Systems, Gentex Corporation. “The FTHS Coxswain contract validates our design process and helmet system innovations while bringing the FTHS Ballistic/Non-Ballistic and FTHS Coxswain Helmets together as one family of headborne systems with interchangeable accessories, common parts and simplified logistics.”

The FTHS Coxswain Helmet System consists of the Ops-Core FAST FTHS Carbon Composite Helmet with modular Ops-Core accessories: Step-In Visors with clear and tinted lenses, NVG Snap Shields, FAST Ballistic and Carbon Composite Mandibles, and FAST Low Profile Ballistic Appliques. Additionally, the helmets will come with a variety of Ops-Core VAS shroud options, helmet covers, ARCTM rails, pads, exterior Velcro and will be available in four sizes with various color/camouflage options. The Ops-Core FAST FTHS Carbon Composite Helmet is available today and commercial versions of the Coxswain Helmet System accessories will be available later this year.

Part of Gentex Corporation’s portfolio of helmet systems for defense, emergency response, and security forces, the focus and dedication of the company’s Ops-Core brand remains the same – protecting elite forces. The modular, scalable, open-architecture design of Ops-Core products allows for the seamless integration and true system level performance.

shop.gentexcorp.com/ops-core-fast-sf-carbon-composite-helmet

CHASE TACTICAL COLUMBUS DAY SALE

20% OFF through 10/14

Coupon Code: COLUMBUSDAY20

GRINNELL, Iowa (October 8, 2019) – The Brownells Retro 4X Carry Handle Optic – designed with fans of the Brownells Retro Rifles in mind – is now in-stock and shipping to customers.

Announced during the 2019 SHOT Show, the Retro 4X Carry Handle Optic closely replicates the look and performance of the original Colt scope made for early models of AR-15-style rifles and carbines.

Manufactured with high-quality Japanese glass to the original factory specifications, it comes with the correct mounting clamp, and as an added touch, the correct inspection sticker on its underside.

Listed as #080-001-373 and retailing for $299.99 at Brownells.com, the Retro 4X Carry Handle Optic fits Brownells Retro Rifles chambered in 5.56 with a mounting hole in the carry handle.

It will not fit on .308 Retro Rifles such as the BRN-10A or BRN-10B, or the 5.56 Brownells Proto rifle, none of which have the required mounting hole in the carry handle.

The Retro 4X Carry Handle Optic quickly and easily attaches to the AR-style carry handle as found on the BRN-16A1, XBRN-177, BRN-601 and similar rifles.

Calibrated for the trajectory of modern 5.56 ammunition, it has elevation adjustments marked in 100-yard increments out to 500 yards.

To see the Brownells Retro 4X Carry Handle Optic, visit www.Brownells.com.

Fountain Valley, CA—SureFire, LLC, manufacturer of the world’s finest—and most innovative—illumination tools and tactical products, will be exhibiting at the 2019 Association of the United States Army’s (AUSA) Annual Meeting & Exposition in Washington D.C. October 14-16. The AUSA Annual Meeting & Exposition is the largest land power exposition and professional development forum in North America. SureFire will be displaying brand new weapon lights, suppressors, flash hiders and much more. Stop by booth #8337 in Hall E to see the latest illumination tools, suppressors, and tactical products from SureFire.

RESEARCH TRIANGLE PARK, N.C. — Antibiotic resistance is a one of the world’s most pressing public health problems. Army scientists have developed a new weapon to combat super-bugs, which could protect Soldiers and fight resistance.

Bacteriophage, a virus that infects and replicates within bacteria, kill bacteria through different mechanisms than antibiotics, and they can target specific strains, making them an appealing option for potentially overcoming multidrug resistance. However, quickly finding and optimizing well-defined bacteriophages to use against a bacterial target is challenging.

Researchers at the MIT Institute for Soldier Nanotechnologies, identified a way to do just that. The U.S. Army established the institute in 2002 as an interdisiciplinary research center to dramatically improve protection, survivability and mission capabilities of the Soldier and of Soldier-supporting platforms and systems.

“This is a crucial development in the battle against these superbugs,” said Dr. James Burgess, program manager, Institute for Soldier Nanotechnologies, Army Research Office, an element of the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory. “Finding a cure for antibiotic-resistant bacteria is particularly important for soldiers who are deployed to parts of the world where they may encounter unknown pathogens or even antibiotic-resistant bacteria. Wounded Soldiers are even more susceptible to infections, and they may come home carrying these drug-resistant bugs.”

In this study, published in Cell, MIT biological engineers showed that they could rapidly program bacteriophages to kill different strains of E. coli by making mutations in a viral protein that binds to host cells. The results showed that these engineered bacteriophages are also less likely to provoke resistance in bacteria.

“As we’re seeing in the news more and more now, bacterial resistance is continuing to evolve and is increasingly problematic for public health,” said Timothy Lu, an MIT associate professor of electrical engineering and computer science and of biological engineering and the study’s senior author. “Phages represent a very different way of killing bacteria than antibiotics, which is complementary to antibiotics, rather than trying to replace them.”

The researchers created several engineered phages that could kill E. coli grown in the lab. One of the newly created phages was also able to eliminate two E. coli strains that are resistant to naturally occurring phages from a skin infection in mice.

The Food and Drug Administration has approved a handful of bacteriophages for killing harmful bacteria in food, but they have not been widely used to treat infections because finding naturally occurring phages that target the right kind of bacteria can be a difficult and time-consuming process.

To make such treatments easier to develop, Lu’s lab has been working on engineered viral scaffolds that can be easily repurposed to target different bacterial strains or different resistance mechanisms.

“We think phages are a good toolkit for killing and knocking down bacteria levels inside a complex ecosystem, but in a targeted way,” Lu said.

The researchers wanted to find a way to speed up the process of tailoring phages to a particular type of bacteria. They came up with a strategy that allows them to rapidly create and test a much greater number of tail fiber variants.

They created phages with about 10 million different tail fibers and tested them against several strains of E. coli that had evolved to be resistant to the non-engineered bacteriophage. One way that E. coli can become resistant to bacteriophages is by mutating LPS receptors so that they are shortened or missing, but the MIT team found that some of their engineered phages could kill even strains of E. coli with mutated or missing LPS receptors.

The researchers plan to apply this approach to target other resistance mechanisms used by E. coli and to develop phages that can kill other types of harmful bacteria.

“Being able to selectively hit those non-beneficial strains could give us a lot of benefits in terms of human clinical outcomes,” Lu said.

The Institute for Soldier Nanotechnologies engages in fundamental, multidisciplinary nanoscience research relevant to the Soldier. In collaboration with Army and industrial partners, this focused nanoscience research creates opportunities for new materials, properties and phenomena that will directly advance modernization efforts. As an Army University-Affiliated Research Center, the institute’s contract is administered and overseen for the U.S. Army by the Army Research Office.

______________________________

The CCDC Army Research Laboratory is an element of the U.S. Army Combat Capabilities Development Command. As the Army’s corporate research laboratory, ARL discovers, innovates and transitions science and technology to ensure dominant strategic land power. Through collaboration across the command’s core technical competencies, CCDC leads in the discovery, development and delivery of the technology-based capabilities required to make Soldiers more effective to win our Nation’s wars and come home safely. CCDC is a major subordinate command of the U.S. Army Futures Command.