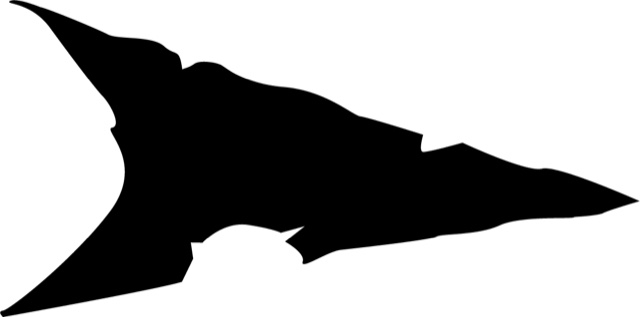

MIDDLETOWN, Pa. – The 193rd Special Operations Wing became the first Air National Guard unit to receive an MC-130J Commando II aircraft Feb. 2 as part of its mission conversion to a flagship mission of Air Force Special Operations Command.

“This is a monumental day for the 193rd, ANG, and AFSOC. The Commando II mission will ensure the 193rd SOW remains not only relevant but also at the forefront of the battlespace for years to come,” said Col. Edward Fink, 193rd SOW commander.

Led by the efforts of Lt. Col. Benton Jackson, unit conversion officer, the wing has been preparing for its mission conversion since 2021. Jackson believes the hard work of 193rd SOW Airmen and the support of the community led to the completion of this first step.

“Seeing the Commando II on our flight line is a tangible symbol of the progress we’ve made as a wing in bringing this versatile mission to central Pennsylvania,” Jackson said. “It’s an exciting time to be a part of this team, and I have the utmost confidence we have the right culture and people to continue with a successful mission conversion.”

For decades, the wing operated the EC-130J Commando Solo as part of the only airborne Military Information Support Operations broadcasting platform in the U.S. military. Col. Jaime Ramirez, 193rd Special Operations Maintenance Group commander, sees the move to the Commando II as a major shift in the unit, AFSOC and ANG.

“The Commando II is the special operations workhorse in that it performs many different types of missions and performs them well,” Ramirez said. “There is no doubt in my mind the aircraft that landed here today will be integral in any future conflict.”

Ramirez said the wing maintained the full operating capabilities of the outgoing aircraft while simultaneously preparing for the arriving mission.

“We were ready to maintain the Commando II well before it arrived, all while never losing a step in maintaining and launching EC-130s,” Ramirez said. “That only happens if you have the best people. I’d put our maintainers up against anyone.”

While the 193rd SOMXG is prepared to maintain the aircraft, the 193rd Special Operations Group is postured to fly them immediately. Col. Gordon Frankenfield, 193rd SOG commander, said his Airmen are very familiar with the aircraft and mission set.

“We’ve executed similar mission sets for years, which likely contributed to AFSOC trusting us with this critically valuable aircraft,” Frankenfield said. “Our goal from Day One has been to operate the Commando II with the same potency as an active duty unit, and our aircrews are trained and ready to make that a reality.”

Frankenfield sees the Commando II’s arrival in Pennsylvania as an important strategic move domestically and abroad.

“The 193rd now offers something the U.S. military didn’t have before,” Frankenfield said. Special Operations Forces based in the Northeast now have a crucial air asset in their backyard to build their combat readiness. Combatant commanders have a much more robust and versatile capability to project air power in different geographic regions.”

The aircraft’s arrival at night was perhaps appropriate given the nature of its mission. The Commando II flies clandestine – or low visibility – single or multi-ship, low-level infiltration, exfiltration and resupply of special operations forces by airdrop or air land and air refueling missions for special operations helicopters and tiltrotor aircraft, intruding politically sensitive or hostile territories.

“The Commando II is the embodiment of Agile Combat Employment and will present complex dilemmas to our adversaries. It’s a shadow in the dark and sends a clear message that the U.S. military owns the night,” Fink said. “The 193rd is ready today to add to the impressive lineage of the Commando II.”

By MSgt Alexander Farver, 193rd Special Operations Wing