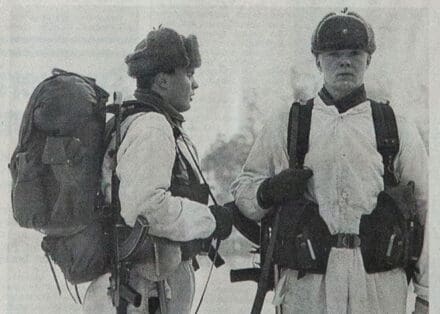

MEADOWS OF DAN, Va. — Project Manager Soldier Survivability (PM SSV), under Program Executive Office Soldier (PEO Soldier), marked the Full-Rate Production (FRP) kickoff of the Aircrew Combat Equipment (ACE) vest at the Aerial Machine and Tool Corp. manufacturing facility, June 4, 2025, in Meadows of Dan, Virginia. The ACE vest represents a major milestone in rotary-wing protection, delivering the Army’s most significant upgrades in more than two decades.

During the kickoff, Maj Caleb Hughes, assistant product manager for PM SSV’s Air Warrior, (AW) Air Soldier Systems and ACE vest program lead, provided a technical overview of ACE program objectives to senior PM SSV leadership focusing on showcasing the vest’s core deliverables, reducing the physical weight borne by the air warrior while enhancing Soldier protection and survivability.

Developed as a Preplanned Product Improvement (P3I) under the Air Soldier System, the ACE vest replaces the legacy Generation III Air Warrior Personal Survival Gear Carrier (PSGC), delivering a 19% lighter system, with a 10% reduction in bulk from the legacy carrier.

“The improvements to form, fit, and function dramatically increase mission effectiveness and survivability,” Maj. Hughes said. “Reducing body-carried weight is key to lowering fatigue and increasing aircrew sustainment during long-duration aviation missions.”

To achieve these efforts, the ACE vest integrates components from the Modular Scalable Vest (MSV) developed under the Soldier Protective Equipment (SPE) portfolio. The MSV’s low-profile soft armor replaces heavier legacy materials while streamlining compatibility with other ACE protective elements.

“The ACE vest is a strong example of cross-platform integration,” said Neal Nguyen, lead systems engineer for SPE. “The MSV’s upgraded soft armor reduces core areal density from 1.8 to 0.78 lb/ft², with a drop in carried weight from 9.3 pounds to 5.61. This transformational capability results in significant improvements to aircrew mobility.”

By aligning the MSV across platforms, PEO-Solider ensures proven ballistic technologies are fielded faster without requiring separate testing or validation from each system team, Nguyen added.

During the kickoff, Maj. Hughes also introduced the laser-cut Pouch Attachment Ladder System (PALS), a modernized textile solution replacing the traditional MOLLE system.

“The PALS eliminates unnecessary bulk from excess stitching and cloth and supports a more flexible gear configuration,” Maj. Hughes said. “This modular capability allows aircrews to tailor the vest based on mission and environmental factors, reducing equipment load without compromising protection.”

The ACE vest includes additional survivability features such as the advanced Personal Restraint Tether (PRT), an attenuating safety line designed to control deceleration during a fall from a rotary-wing platform.

“The tether helps reduce the jolt a crew member might otherwise experience during a fall,” Maj. Hughes said. “Instead of a hard stop that could cause secondary injuries, the design absorbs energy and enhances recovery safety.”

Another notable upgrade to Aircrew survivability is the repositioned Life Preserver Unit (LPU-42/P) floatation device, now mounted at the abdomen. The configuration increases the head’s range of motion, reducing fatigue and enhancing situational awareness during flight operations and water egress scenarios. The LPU-42 redesign also increases buoyancy by nearly 39%, a critical survivability improvement delivered through the ACE vest.

Following the technical presentation, senior leaders toured the production facility, observing elements of the ACE vest manufacturing line and Aerial’s recent technology upgrades implemented to support product development. The event concluded with a complete product layout, offering a firsthand look at the ACE vest’s fielded components and marking the milestone in the program’s transition to full-rate production.

“Today’s event highlights the culmination of hard work and collaboration across the Army to deliver the first update to Aircrew protection in more than 20 years,” said Col. James Lindh, Project Manager of Soldier Survivability. (PM SSV) “This dramatic increase in protection and comfort will make our Aircrews more lethal and survivable. This milestone reflects our commitment to delivering the best kit for our Aircrews available today, while supporting Army-wide modernization.”

Limited procurement for the ACE system began in fiscal year 2022, followed by initial fielding in FY24 to the 25th Combat Aviation Brigade and rapid delivery to elements of the 101st Airborne Division (Air Assault) at Fort Campbell, Kentucky, earlier this year. The ACE vest and modular component fielding will continue through FY32 based on aviation unit priorities.

“Supporting the Air Warrior mission means ensuring these systems are fielded where they are needed most,” said Maj. Hughes. “What this event means for the Aviator, is delivering the best equipment to the field faster.”

Story by Khylee Woodford

PEO Soldier