NP Aerospace, the global armour manufacturer and vehicle integrator, has formed a strategic partnership with ITEN Defense, a US-based specialist in opaque and transparent armour technologies. The partnership brings together two highly complementary businesses to deliver an enhanced, locally supported specialist armour and survivability engineering offering to the US market, alongside selected wider global opportunities.

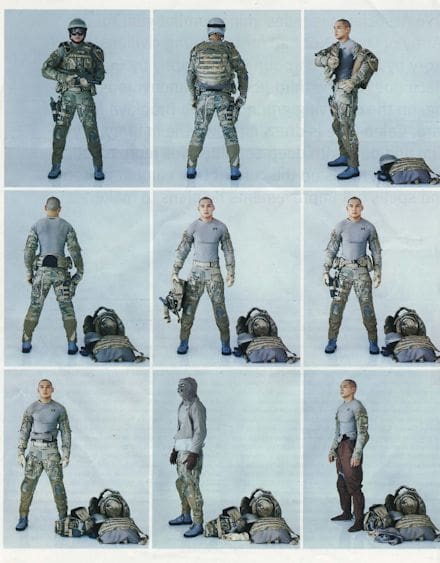

Over the last seven years, NP Aerospace has significantly expanded its global survivability and protection portfolio, establishing itself as a mid-tier defence business with a strong international footprint. The company provides turnkey survivability solutions across land, maritime, and aerospace platforms, underpinned by a comprehensive platform armour product range. This includes advanced composite vehicle armour systems, mission-specific platform protection kits, and a leading personal protection portfolio encompassing proprietary helmet shell technologies and high-end specialist ballistic plates designed to meet demanding military requirements.

ITEN Defense is a US-based armour manufacturing specialist with advanced materials processing and integration capabilities across both opaque and transparent armour. The company has built a strong reputation for process engineering expertise, rapid prototyping, and the delivery of high-volume, high-performance armour solutions optimised for US defence and law enforcement programs, with a particular focus on domestic manufacturing, quality assurance, and responsive customer support.

The partnership announcement, which coincides with SHOT Show in Las Vegas, USA, this week (20-23 January 2026), establishes a framework for both companies to explore joint manufacturing and market access opportunities. NP Aerospace and ITEN Defense will collaborate across a range of upcoming US platform armour opportunities spanning land, maritime, and aerospace domains. In parallel, the partnership will extend into personal protection programs for military customers and OEMs, combining NP Aerospace’s deep expertise in composite armour systems engineering, vehicle survivability, helmet shell and specialist body armour plate technologies with ITEN Defense’s advanced materials design and large-scale production capabilities.

James Kempston, Chief Executive Officer of NP Aerospace, said: “This partnership brings together the complementary strengths of both companies and reflects a shared intent to explore how, together, we can support our customers. By working with ITEN Defense, we are seeking to strengthen our US market access, enhance manufacturing resilience, and respond to increasing demand for locally supported high-performance protection solutions for military platforms and the individual soldier.”

Damon Walsh, Chief Executive Officer of ITEN Defense, added: “NP Aerospace is a highly respected partner in the global survivability and protection space and we’re looking forward to working closely with them to continue our collective tradition of protecting those in harm’s way. We’re proud to have established this partnership as it brings together two highly skilled and experienced businesses to improve market access for both parties while delivering best-in-class capability, innovation, and value to our customers.”