ARLINGTON, Va. — February 26, 2026 — AeroVironment, Inc. (“AV”) (NASDAQ: AVAV), a global leader in autonomous systems and precision strike solutions, today announced receipt of a $186 million delivery order from the U.S. Army for Switchblade® 600 Block 2 and Switchblade® 300 Block 20 explosively formed penetrator (EFP) loitering munition systems.

The order was issued under the Army’s existing five-year, $990 million Indefinite Delivery, Indefinite Quantity (IDIQ) contract for Lethal Unmanned Systems (LUS), which was awarded in August 2024. This delivery order marks the U.S. Army’s first procurement of AV’s next-generation Switchblade product line, underlining a significant step forward in fielding advanced, precision loitering munitions across infantry and maneuver formations. It is the Army’s first Switchblade order containing EFP payload, delivering enhanced lethality against armored threats.

“This delivery order reflects the Army’s confidence in the next evolution of the Switchblade family and its relevance to modern, contested battlefields,” said Brian Young, Senior Vice President of Loitering Munitions at AV. “Switchblade 600 Block 2 and Switchblade 300 Block 20 build on years of combat experience while delivering meaningful upgrades in autonomy, resilience, and lethality tailored to today’s operational demands.”

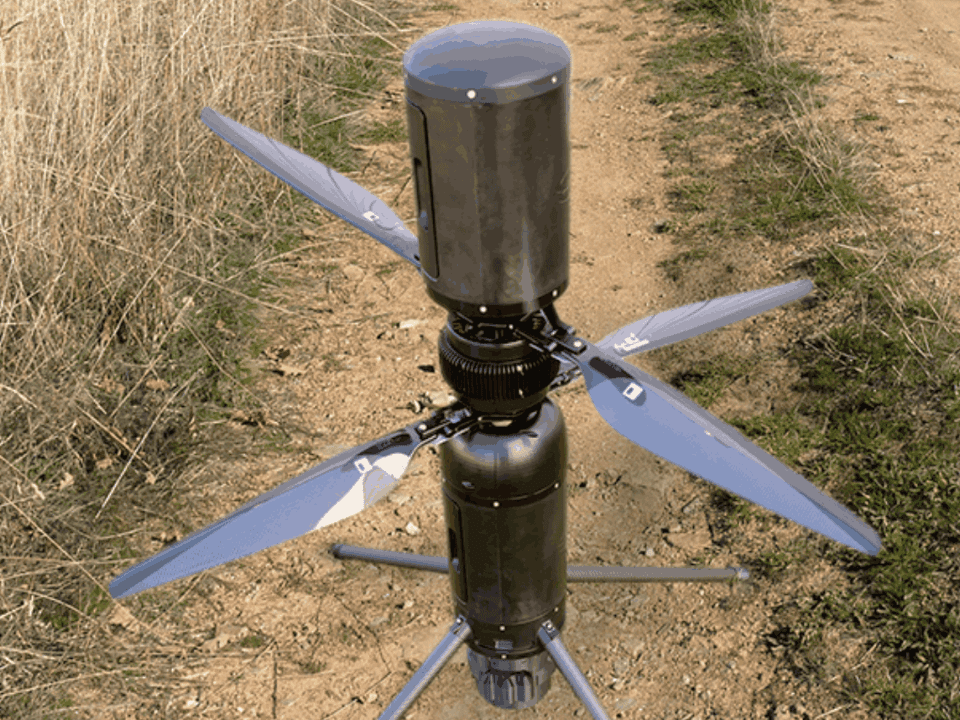

Switchblade 600 Block 2 is AV’s most advanced long-range loitering munition to date, designed for multi-domain operations and ruggedized for maritime and highly contested environments. Developed in collaboration with United States Special Operations Command (SOCOM), the system features upgraded avionics and advanced Automatic Target Recognition (ATR), enabling faster detection, identification, and engagement of threats. Integrated resilient communications, including Silvus MANET radios, support distributed operations and extended handoff ranges, while improved navigation and mission resilience allow effective employment in GPS-challenged environments. These upgrades provide commanders with increased reach, flexibility, and confidence against armored and high-value targets.

Switchblade 300 Block 20 introduces a new modular payload capability to the combat-proven, backpackable loitering munition. For the first time, the Army has procured the system with an Explosively Formed Penetrator (EFP) payload, delivering enhanced lethality against armored threats while retaining the speed, portability, and ease of use that have made Switchblade 300 a trusted solution at the small-unit level. The Block 20 configuration also includes sensor improvements, enhanced user interfaces, and extended range options, allowing rapid, precision effects beyond line of sight.

Together, the Switchblade 600 Block 2 and Switchblade 300 Block 20 provide the Army with a scalable family of precision loitering munitions—from lightweight, single-operator systems to long-endurance, multi-domain capabilities—designed to operate seamlessly across echelons and mission sets.

“This delivery order further advances the Army’s Lethal Unmanned Systems Directed Requirement and reinforces AV’s role as the leading provider of combat-proven loitering munition systems,” said Young. “As we continue to invest in expanding Switchblade manufacturing capacity and accelerating delivery timelines, we are continuing to meet the growing demand for these products from U.S. and allied forces.”

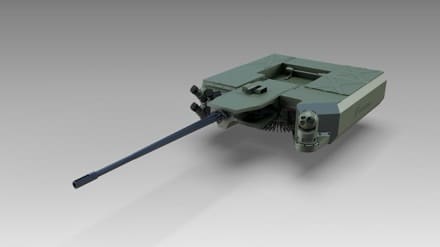

Rheinmetall is further expanding its role as a leading manufacturer of 120mm tank ammunition. The NATO Support and Procurement Agency (NSPA) has called off its first batch of ammunition, worth around €200 million, under a 2025 framework agreement for 120mm ammunition, a contract of substantial scope and value. The end customers are various NATO countries.

Rheinmetall is further expanding its role as a leading manufacturer of 120mm tank ammunition. The NATO Support and Procurement Agency (NSPA) has called off its first batch of ammunition, worth around €200 million, under a 2025 framework agreement for 120mm ammunition, a contract of substantial scope and value. The end customers are various NATO countries.