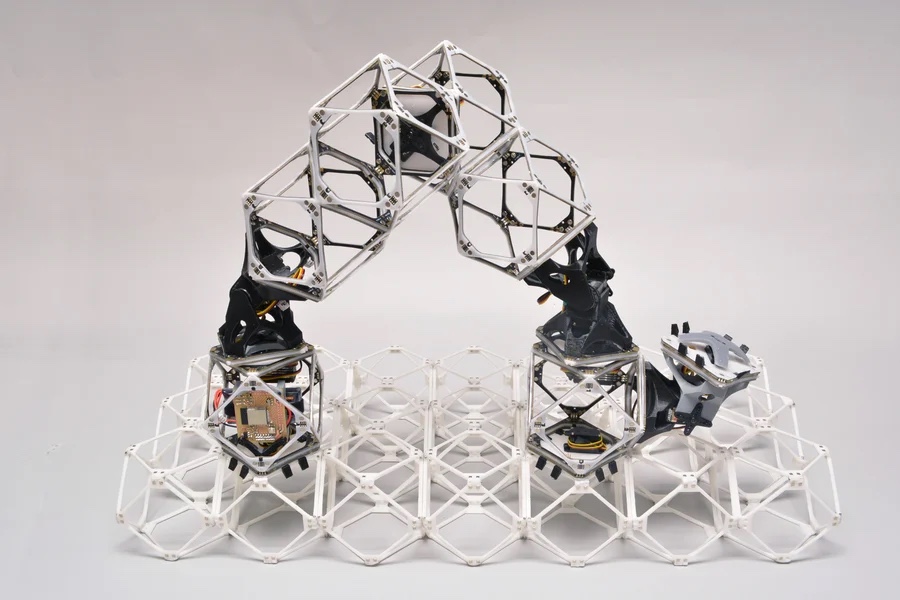

According to an article in Nature, Massachusetts Institute of Technology’s Center for Bits and Atoms (CBA) has developed self-replicating hierarchical modular robotic swarms. That sounds kind of ominous as so many of us are concerned with the use of robotic swarms to overwhelm defenses.

But there’s a word you need to add to your vocabulary and that’s “Voxel”. Some are familiar with the mathematical definition:

Voxel is an image of a three-dimensional space region limited by given sizes, which has its own nodal point coordinates in an accepted coordinate system, its own form, its own state parameter that indicates its belonging to some modeled object, and has properties of modeled region.

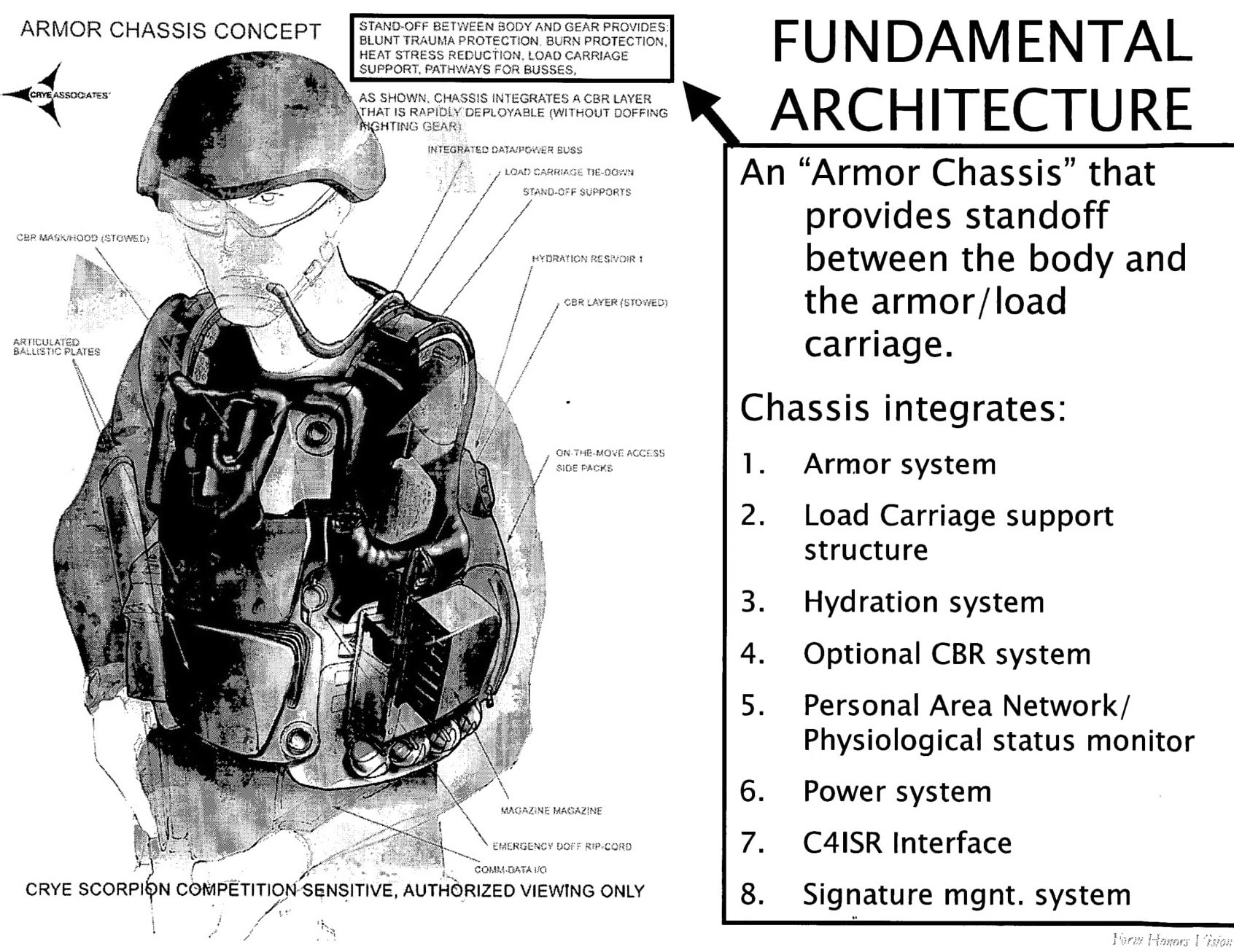

There’s another use of the term and that’s in regard to robotics. Voxels are also small robots, generally uniform in size and structure which can be used as components to build a larger robot: kind of like Lego or other construction sets you used as a kid. However, these voxels do so much more. They not only offer mechanical function but can now transit power and data to one another.

You can easily see how these robots can be used for assembly and that these structures will make us question what a robot is as its functionality becomes inherent in many new things which go beyond what we currently consider a robot.

The robots themselves consist of a string of several voxels joined end-to-end. These can grab another voxel using attachment points on one end, then move inchworm-like to the desired position, where the voxel can be attached to the growing structure and released there.

Assembler robots building bigger versions of themselves are just the beginning. Eventually, we will see systems which can reconfigure themselves, shapeshifters if you will, as their purpose changes.

What’s more, they could be capable of repairing themselves by replacing voxels as they are worn out or damaged. Let that sink in. The implications are enormous and may quite possibly change the order of things.