Leaning into the Teutonic theme, Galvion is giving away this helmet during this year’s Enforce Tac.

FULDA, GERMANY (19.02.2026)

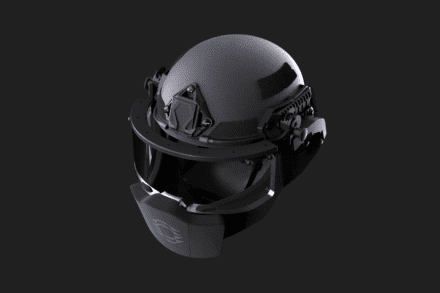

With the “Omega Jaw” mandible guard, Mehler Protection is introducing a new generation of face and jaw protection specifically designed for threats from AK47 MSC projectiles in accordance with VPAM 6, while fully maintaining system compatibility with Mehler Protection’s ultra-lightweight high-cut helmets. “This development underlines our ambition to drive innovation in our industry. Our products are based on operational requirements and are designed to provide optimum protection and genuine reliability,” explains Dr Mario Amschlinger, CEO Mehler Systems.

Homogeneous head protection against rifle ammunition

With Omega Jaw, Mehler Protection is transferring its long-standing expertise in ballistic body armour to face and jawprotection. Whereas conventional helmet/face protection combinations generally provide only limited protection against handgun ammunition and basic fragmentation protection, the system achieves a maximum protection level against AK47 MSC projectiles at a velocity of 720 m/s (VPAM 6 level) with minimal frontal deformation. This closes a critical protection gap and, for the first time, enables logically coordinated, complementary face protection.

The ballistic high-cut helmet of the Omega series can be upgraded to protection level VPAM 6 by attaching ultra-lightweight plates made from ultra-high molecular weight polyethylene (UHMWPE). These ugradeable plates are an essential component of the holistic VPAM 6 protection architecture. In combination with the mandible guard, the reinforced helmet provides homogeneous all-round head protection.

“In line with the current trend towards enhanced protection for face and head areas, Omega Jaw is a real game changer,” say the mandible guard designers, Dr Christian Rödel and Marie Schmidt. “For the first time, operators have access to a face and jaw protection solution that provides protection against AK47 rounds, integrates seamlessly into our ultra-lightweight high-cut helmets and at the same time maintains compatibility with mission-critical accessories. This is a decisive step towards homogeneous head protection for highly critical operational environments.”

Seamless integration into high-cut helmets with no design modifications

Omega Jaw is attached to the high-cut helmet shell via a specially developed U-profile that locks onto the helmet rim. This ensures secure and rapid system integration without altering the basic helmet design. The three-piece plate structure deliberately incorporates overlaps both between the plates and at the helmet interface in order to minimise vulnerabilities and ensure the most continuous protective surface possible. Despite the extended protection area, Omega Jaw is engineered for full compatibility with common hearing protection and communication headsets such as Peltor systems and can be used in combination with the Mehler Protection helmet visor.

Modular textile and plate concept with tactical interfaces

The textile cover concept allows the integration of different protective plates, supporting scalable protection levels as well as future material upgrades. At the same time, the design offers valuable mounting options on Picatinny rails, enabling users to attach tactical equipment without compromising protection. The system can be quickly donned and doffed using hook-and-loop straps and is designed for compact stowage during transport or when not in use.

Stop by to experience the complete product line including the FAST® helmet system, the global standard trusted by Global Special Operations Forces and Nation Police SWAT teams worldwide. Ops-Core’s fully integrated system seamlessly combines optics, respiratory protection, and AMP® communication headsets to deliver lightweight protection, enhanced situational awareness, and uncompromised performance.

Available through the NSPA contract, Ops-Core solutions simplify procurement and accelerate fielding for allied forces.

Visit Us in Booth 7-747 alongside our German partner IEA MIL-Optics GmbH in Nuremberg to see how we continue to define the future of integrated headborne capability!

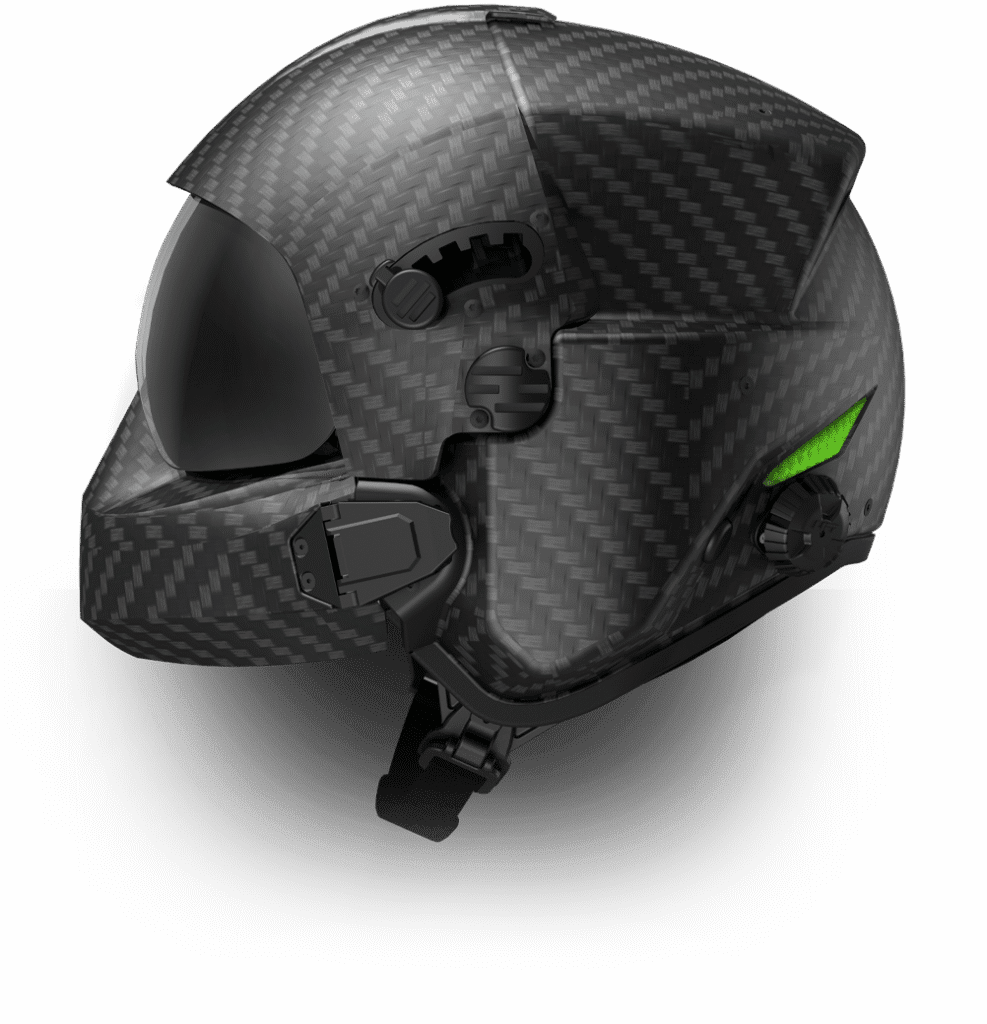

Carson City, NV – LIFT Aviation and LIFT Airborne Technologies proudly announce the launch of the AV3 Assault, a Next-Generation Rotary Wing Helmet, engineered for Department of War personnel, Military Contractors, and General Aviation helicopter pilots. Designed from the ground up for modern rotary wing operations, the AV3 Assault delivers a powerful combination of advanced protection, mission adaptability, and all-day comfort.

Designed for uncompromising performance, the ALSE/DOI-certified AV3 Assault features a lightweight carbon fiber shell paired with a next-generation EPS impact frame integrated with Koroyd® impact protection plates. This advanced construction delivers exceptional impact protection while enhancing airflow for sustained comfort in demanding operational environments. A Quick-Adjust Nape Fit System and two-piece DriFire® Airmesh Comfort Linerwork together to provide a secure, breathable, and moisture-wicking fit, with precise adjustability across a wide range of head sizes.

The AV3 Assault is engineered for mission versatility and advanced system integration, including:

Optimized weight distribution and a refined center of gravity reduce neck fatigue without compromising protective performance, allowing pilots to stay focused during demanding rotary wing operations.

Whether operating in combat zones or executing the most demanding flight profiles,. the AV3 Assault sets a new standard for Rotary Wing Helmet protection, comfort, ventilation and performance. Meeting the evolving demands of today’s aviation professionals across military, contractor, and civilian applications.

The AV3 Assault will make its official debut at Verticon 2026.

www.liftairborne.com/av3-rotary-wing-helmet

Galvion, a world leader in the design and manufacture of innovative head systems, power and data management solutions, and integrated soldier systems, unveils the Batlskin Hellbender™ UL (Ultra-Light) helmet — a new ultra-lightweight ballistic head system developed to meet the evolving needs of modern armed forces operating at scale and seeking force-wide standardization without compromising performance. Galvion’s Hellbender™ UL launch coincides with EnforceTac 2026, taking place in Nürnberg, Germany, from 23–25 February. The new Hellbender UL, along with Galvion’s wider range of head systems and power and data solutions, will be on display at booth 9-556.

Galvion’s Hellbender™ platform has been fielded across multiple international programs to meet a variety of requirements. Notably, in August 2025, Galvion announced the award of a USD 130 million contract by the United States Marine Corps (USMC), having selected a variant of Galvion’s Hellbender platform for their Integrated Helmet System (IHS) program. This latest variant, the Hellbender UL, benefits from insights and feedback from a broad range of users over multiple years of development and in-field use across a wide range of operational theatres.

Engineered as a complete head system, the Hellbender™ UL is designed to deliver superior protection through enhanced shell geometry. Using an innovative manufacturing process that offers increased ballistic performance while reducing overall weight, the design results in exceptional structural rigidity and impact resistance. The helmet is available in four sizes (S–XL) and two cuts, including a Mid/Full cut that provides the ideal balance between maximum coverage and effortless communications integration. Featuring a low-profile, rattle-free shroud, ballistic hardware, and integrated cable channels and pass-throughs to minimize snag hazards, the helmet is designed to provide optimized coverage and stability while maintaining compatibility with face shields, night-vision devices, chem/bio masks, and other mission-critical systems. With Galvion’s best-in-class Apex™ liner system, which combines full-coverage impact protection with a highly adjustable fit architecture, Hellbender UL offers stability, comfort, and endurance over extended wear. Designed with future integration in mind, Hellbender™ UL provides a scalable foundation capable of supporting Galvion’s Cortex™ advanced computing and digital capabilities as operational requirements evolve.

Galvion’s approach to helmet system development is underpinned by proven regional production and delivery at scale. The company has invested significantly in localized manufacturing and supply-chain capability in Europe, including the establishment of its European Production Hub in Poland to support the delivery of 250,000 Caiman® helmets ordered to date through its NATO Support and Procurement Agency (NSPA) framework contract. As European forces continue to modernize their soldier systems, Galvion is committed to extending this regionalized model to support expanded adoption of its helmet platforms, including Hellbender™ UL.

Jonathan Blanshay, Executive Chairman of Galvion, said: “The Hellbender UL is an ultra-lightweight platform that is a high-performing solution aligned with the evolving needs of NATO and European forces, particularly those who require a full cut system. This is a milestone addition to our lightweight helmet portfolio, complementing our widely fielded Caiman® system, and exemplifies our system-level approach that considers not only protection, but also integration, sustainment, and future capability growth. This helmet is designed for forces that expect their equipment to evolve with them, without compromise.”

The innovative plate is based on a unique ceramic pressing and plate-construction technology, delivering high-level ballistic protection while incorporating a curved chest area in multiple sizes. This design eliminates weak seams and expands protection in the critical chest area, ensuring maximum coverage without compromising ballistic integrity.

When combined with SOURCE’s contoured soft ballistic panel, the system provides maximum coverage and improved fit. Flat hard plates paired with flat or partially contoured soft armor leave gaps around the chest and abdomen, while the integration of a contoured hard plate with a curved soft panel fully closes these gaps, offering enhanced ballistic coverage, improved ergonomics, and greater operational confidence.

This development builds on SOURCE’s proven experience in female soft armor solutions, already fielded by operational forces including the Italian Carabinieri, and reflects the company’s continued investment in women-specific protection driven by real-world operational requirements.

Beyond ballistic armor, SOURCE Tactical Gear continues to expand its capabilities across additional domains. The company has established a dedicated helmet manufacturing facility. Produced using advanced materials and innovative manufacturing technologies, the helmets are designed to deliver uncompromising ballistic performance while reducingweight compared to existing solutions on the market. Built to support the development and integration of advanced and disruptive technologies, the facility is already operating at high capacity, with innovative helmet solutions expected to be introduced to customers worldwide.

“Effective ballistic protection depends on precise anatomical fit and advanced materials engineering,” said Dovik Gal, Marketing Manager at SOURCE Tactical Gear. “By combining a first-of-its-kind contoured hard armor plate with curved soft ballistic panels and proprietary ceramic pressing technologies, we eliminate critical coverage gaps and deliver higher ballistic performance for women in operational environments, while continuing to invest in next-generation protective systems.”

In parallel, SOURCE continues to advance its operational gear portfolio, including its ACS rapid-access pouches, designed to improve speed, safety, and efficiency for modern military and law-enforcement forces.

Coming soon from Shaw Concepts is their ARC Helmet Cover.

The team went over it with me during SHOT Show and it will fit both the USMC issue ECH as well as USSOCOM’s FAST SF from Gentex. They’ve designed it so that it will fit different sized helmets as well.

The ARC Cover will be available in The cover will be available in various camouflage patterns, including MARPAT Woodland, MARPAT Desert, MultiCam, Woodland, MultiCam Tropic, and MultiCam Arid. As you can see from the photos, it’s well laid out for cable routing and accessory attachment.

The BRAIN or Balance, Retention & Anchoring Integrated Node Pouch is available now and seen above in Black. More than just a counterweight pouch, it also offers space for spare batteries

The ARC Helmet Cover is coming soon from Shaw Concepts.

WARQ exhibited their new GEN 2 Force-on-Force Helmet.

Enhancements:

• EN 1385 bump certified: The only bump-certified force-on-force helmet on the market.

• D3O Halo 7 pad system: Advanced blunt impact absorption.

• Reinforced fiberglass shell.

• Improved sizing ratchet and retention system.

These are on top of the existing features of the helmet:

• Complete anti-fog ventilation system

• Extra-wide 210° visor for enhanced situational awareness

• One-size-fits-all adjustability

• Made in Europe

• EN 166A and ASTM F1776 certified protection standards

• Industry leading 5 year warranty

Available through Rampart USA.